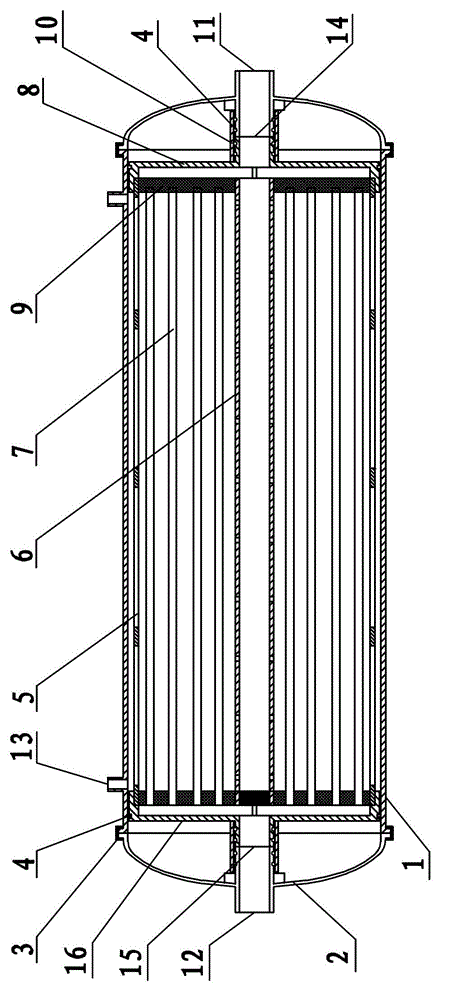

Ultrafiltration membrane component

A technology of ultrafiltration membranes and components, applied in ultrafiltration, membrane technology, semipermeable membrane separation, etc., can solve the problems of material cost waste, difficult cleaning, scrapping of ultrafiltration membrane filaments and membrane shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] Embodiment 1, the diameters of the water outlet 15 and the water inlet 14 are set to be consistent with the diameters of the clean water outlet 12 and the raw water inlet 11 , and the openings with the same diameters can be docked during implementation.

Embodiment approach 2

[0022] Embodiment 2, the diameter of the mouth of the water outlet 15 and the water inlet 14 is set to be larger than the diameter of the mouth of the purified water outlet 12 and the raw water inlet 11, so that the water outlet 15 and the water inlet 14 can be sleeved on the purified water outlet 12 and the raw water inlet 11, and the front end of the water outlet 15 and the water inlet 14 is against the fixed block provided in the end cover 2, and in specific implementation, the water outlet 15 and the water inlet 14 are set outside the clean water outlet 12 and the raw water inlet 11, and the outlet The front ends of the water inlet 15 and the water inlet 14 are respectively against the fixed blocks on the end cover 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com