Device for filling a container with solid particles comprising a diaphragm

A technology of solid particles and equipment, which is applied in the field of container filling solid particles, can solve problems such as difficult filling parameters, suboptimal filling, blockage of concentric tubes, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

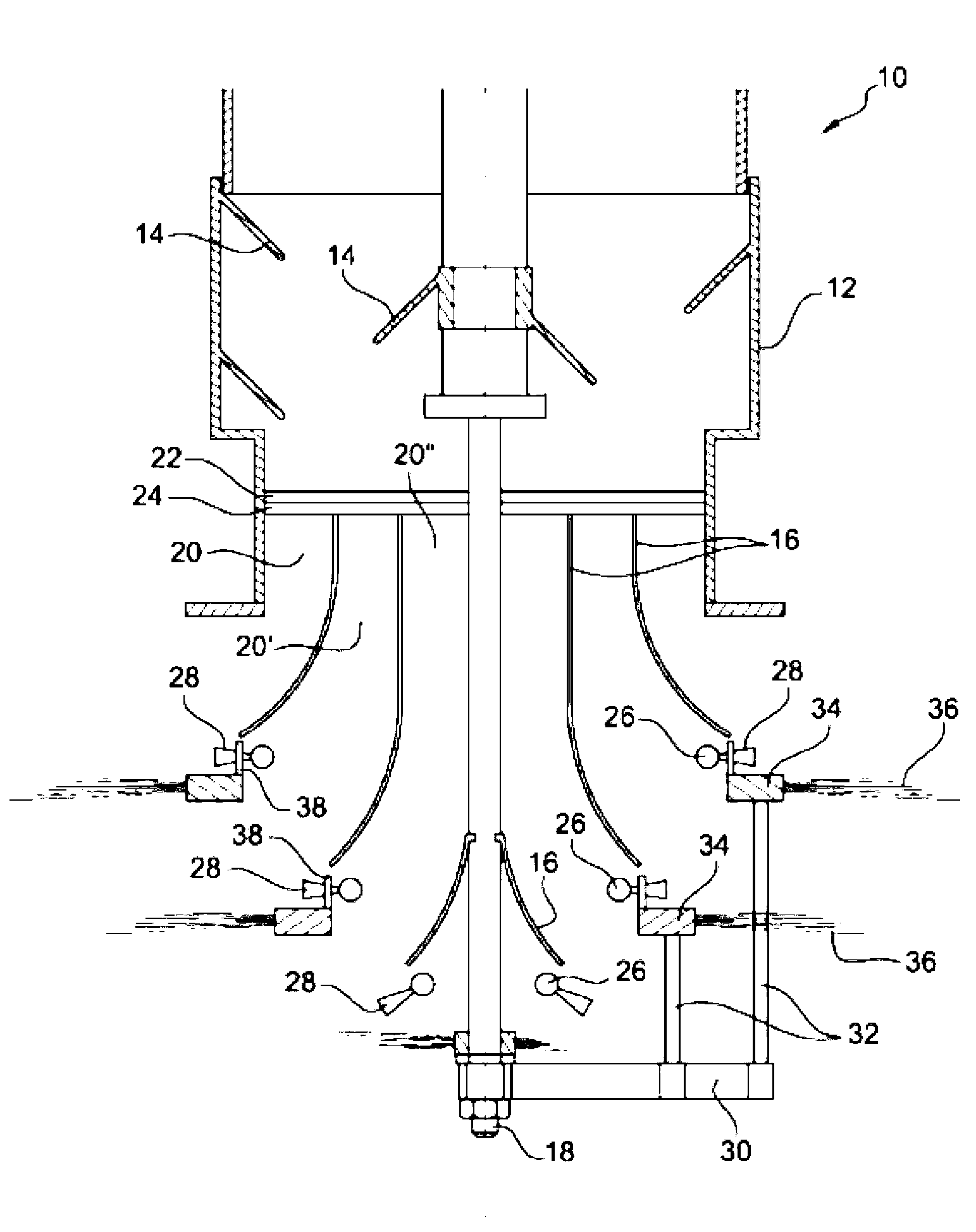

[0037] exist figure 1An apparatus 10 for filling a container (not shown) with solid particles is shown, the apparatus 10 comprising a reservoir 12 which receives solid particles in bulk. In this example, the particles are catalyst pellets for petrochemical reactors. It is to be noted that the diameter of the container to be filled with solid particles may be relatively large compared to the diameter of the device. Thus, the diameter of the container to be filled can vary between 0.5 and 15 meters, while the external diameter of the device can be comprised between 0.1 and 2.5 meters.

[0038] In the embodiment shown here, the reservoir 12 includes a brushed deflector 14 which allows distribution by deflecting the flow and causing the solid particles to mix with each other before they are dispensed into the container. Solid particles. In fact, the flow of solid particles in the reservoir tends to cause separation of the particles: longer particles tend to flow towards the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com