Semiconductor laser aging method and fixing clamp

A technology for fixing fixtures and lasers, used in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of no automatic device and little application significance, and achieve the effect of easy operation, convenient operation and reduced burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

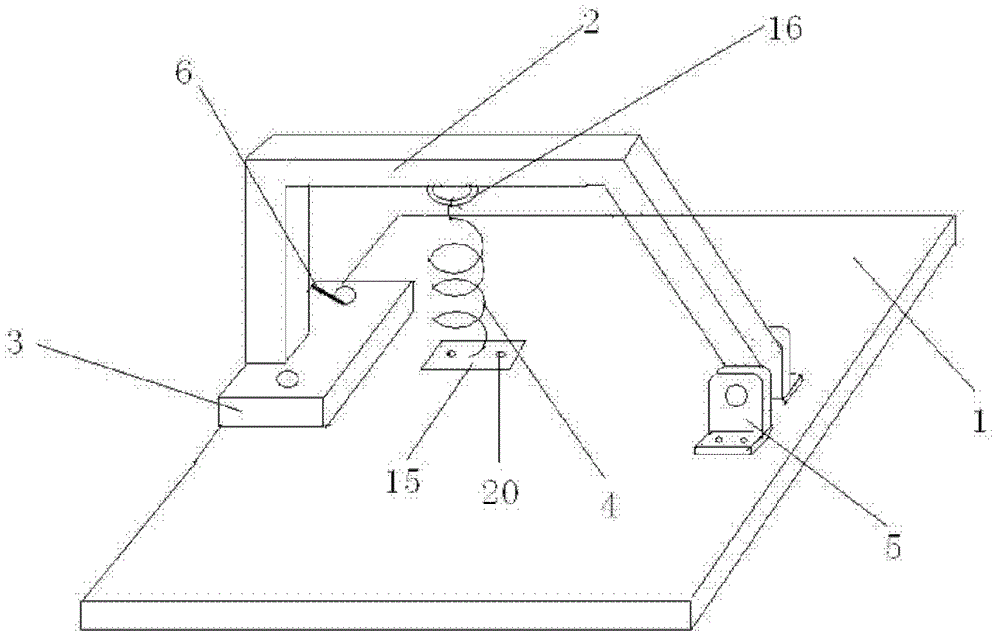

[0038] Embodiment 1: A kind of laser aging jig, the structure is as follows figure 1 -5 shown.

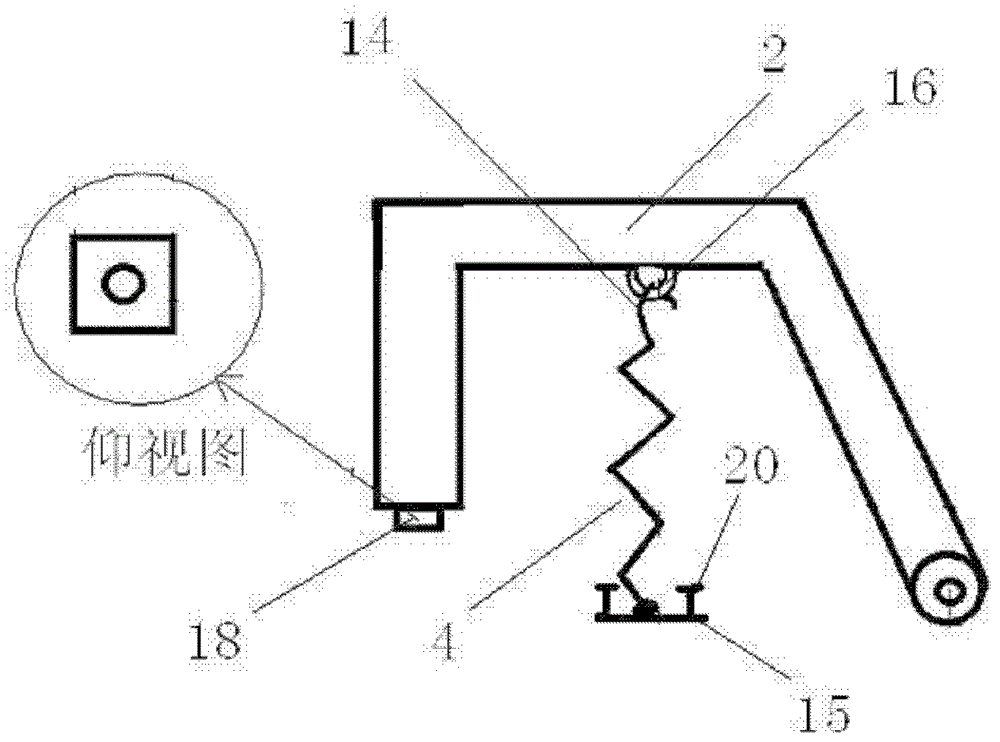

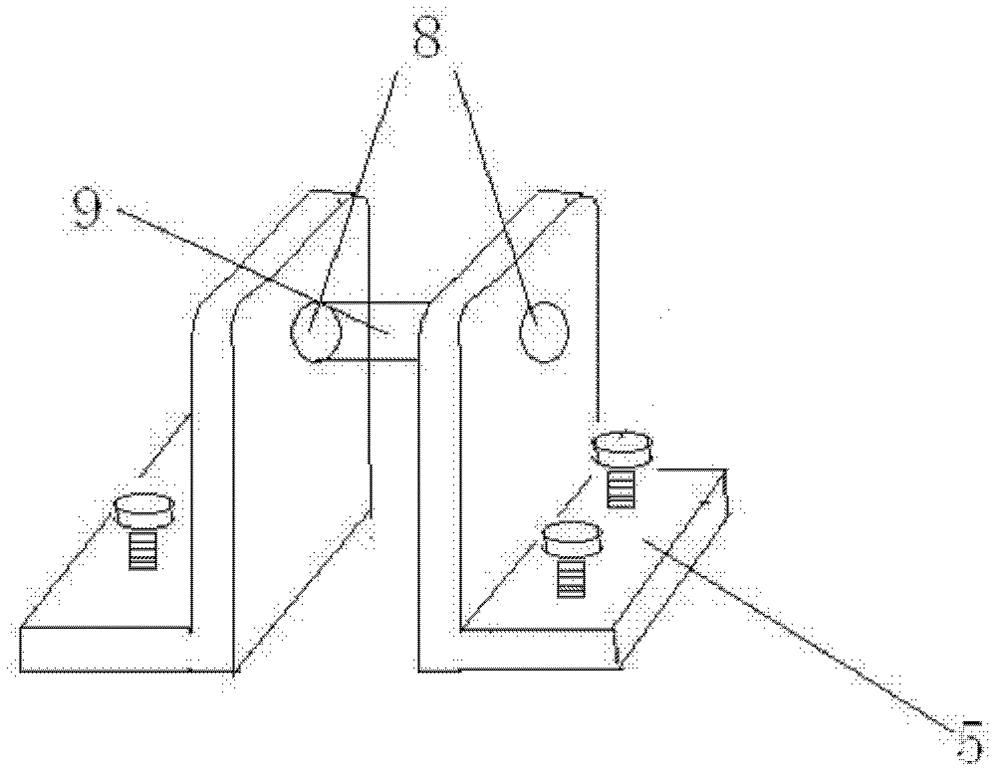

[0039] The laser aging fixture is mainly composed of a base 1, a fixed rod 2, a base 3, and a spring 4. The base 1 is used for fixing the base 3 , the fixing rod 2 and the spring 4 . The base 3 is fixed on the base by screws 7; the fixed rod 2 is a bow-shaped cross-arm structure, which is composed of a vertical arm, a horizontal arm and an oblique strut. In 9, the fixing piece includes two L-shaped angle irons 5, and there are shaft holes 8 on the L-shaped angle irons 5, and the fixed rod 2 is connected with the L-shaped angle irons through a circular shaft 9, and the L-shaped angle irons are fixed on the base On, whole fixed rod 2 can rotate up and down; Fixed rod 2 horizontal arms are provided with hanging ring 16, and the base just below this hanging ring 16 is fixed with cylindrical spring 4, and spring 4 upper end is provided with hook 14, is used for spring 4 is hung on t...

Embodiment 2

[0043] Embodiment 2. A semiconductor laser aging method, using the laser aging jig in Embodiment 1.

[0044] The structure of the laser is as Figure 6 As shown, the main structure includes heat sink 12 , transition electrode sheet 11 , screw hole 13 , and tube core 19 .

[0045] Proceed as follows:

[0046] (1) if Figure 7 As shown, the heat sink 12 equipped with the laser is placed in the groove 10 of the base 3, and then the transition electrode sheet 11 of the laser is fixed on the negative electrode sheet 17 of the base 3 with a clip bar 6, and then the fixing rod The bottom surface of the end of the vertical arm of 2 is pressed on the laser heat sink 12, and the hook 14 of the spring 4 is hung in the hanging ring 16 on the cross arm of the fixed rod 2, and the spring 4 provides downward pressure for the vertical arm of the fixed rod 2, The end of the vertical arm of the fixing rod 2 is pressed against the heat sink 12 of the laser.

[0047] (2) The negative electrod...

Embodiment 3

[0049] There are several working units on one base at the same time. When making the aging fixture, the size of the base can be increased, and then multiple sets of aging devices consisting of bases, fixing rods and springs as described in Embodiment 1 can be installed on one base. The working unit mechanism increases the actual utilization value of the fixture and is more conducive to industrial production. The specific aging method is then the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com