Composite swing type joint bearing service life testing machine

A joint bearing and life test technology, applied in the direction of mechanical bearing testing, etc., can solve the problem of low test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

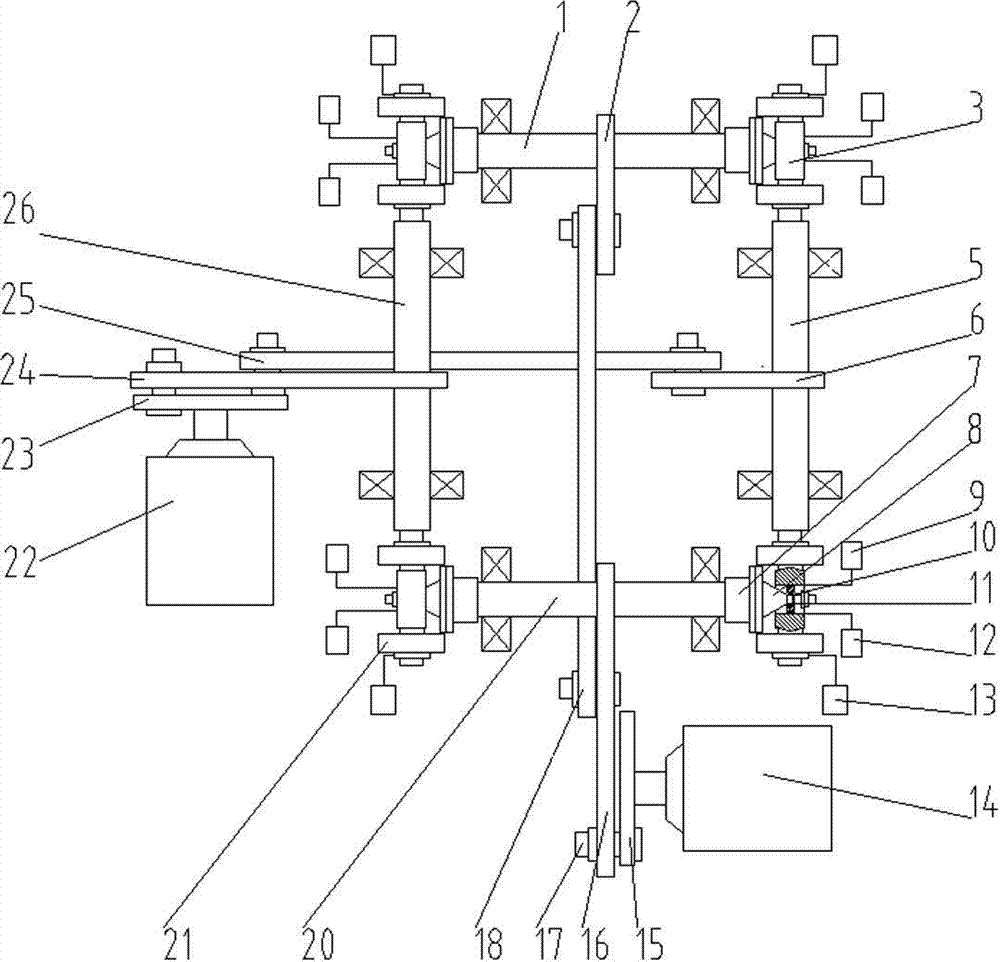

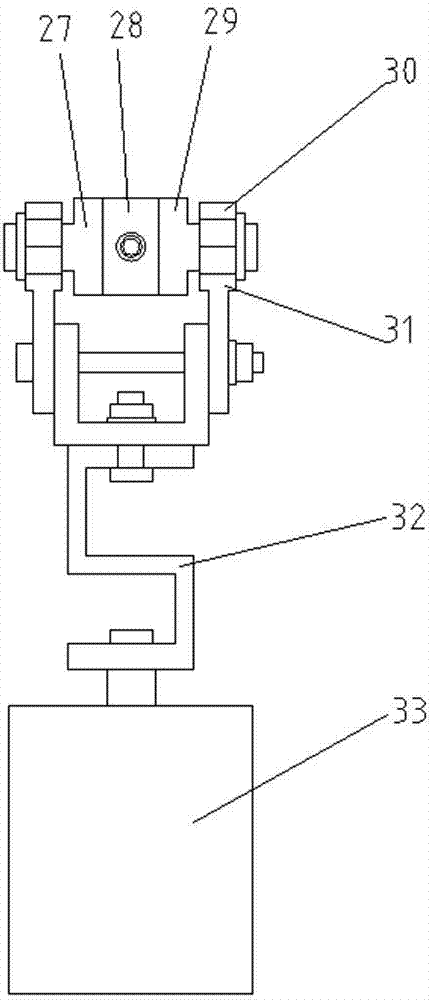

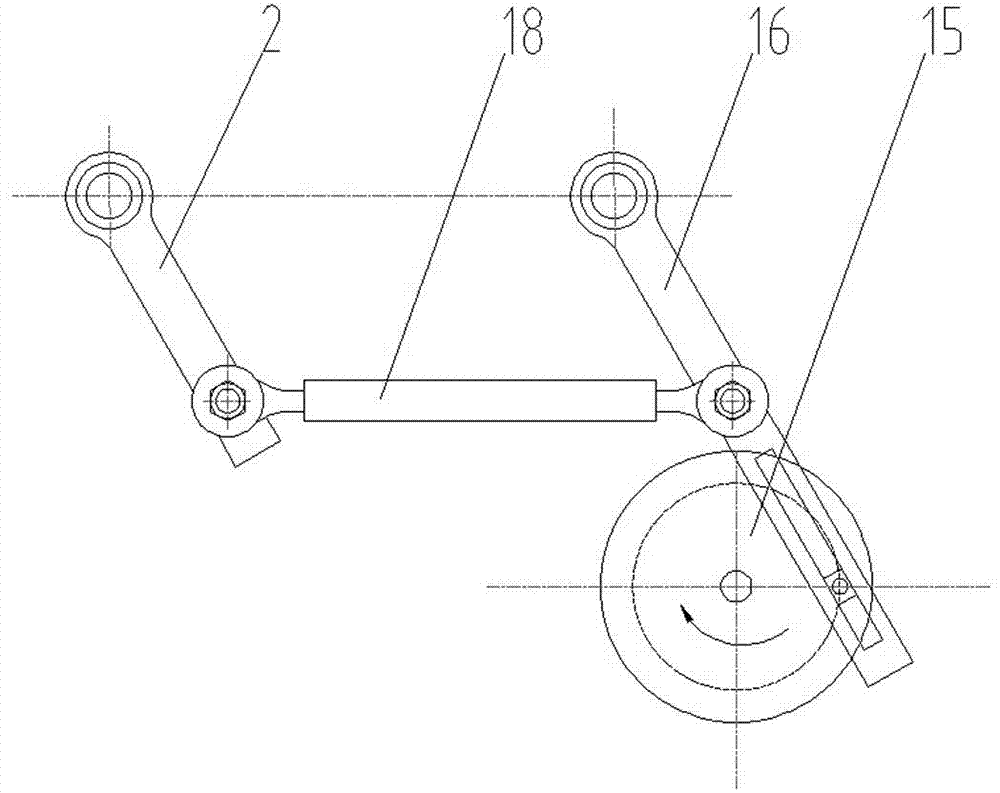

[0017] Such as Figure 1 to Figure 3 As shown, an embodiment of a composite swing type joint bearing life testing machine, the testing machine in this embodiment includes a first axial transmission shaft 1 and a second axial transmission shaft 20 arranged in parallel, and the two axial transmission shafts are used for The inner ring of the joint bearing to be tested is connected by coaxial transmission, and each axial transmission shaft is rotatably assembled in two bearing seats. The two ends of each axial drive shaft here are respectively installed with two flanges through a key connection structure. The flange 7 is equipped with a pin shaft 8 through the end face positioning, and the flange 7 is connected by bolts. The pin shaft 8 is fixedly connected to the pin shaft plate 8. The side of the pin shaft plate 8 away from the flange plate 7 is convexly provided with a pin shaft arranged coaxially with the axial drive shaft for assembling the joint bearing 10, when the joint be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com