Boiler control and combustion optimization method

A combustion optimization and boiler control technology, which is applied in the control of combustion, control system, steam generation, etc., can solve the problems of difficult control of the boiler system, and achieve the effect of ensuring stability, high economic benefits, and solving difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Thinking of the present invention is as follows:

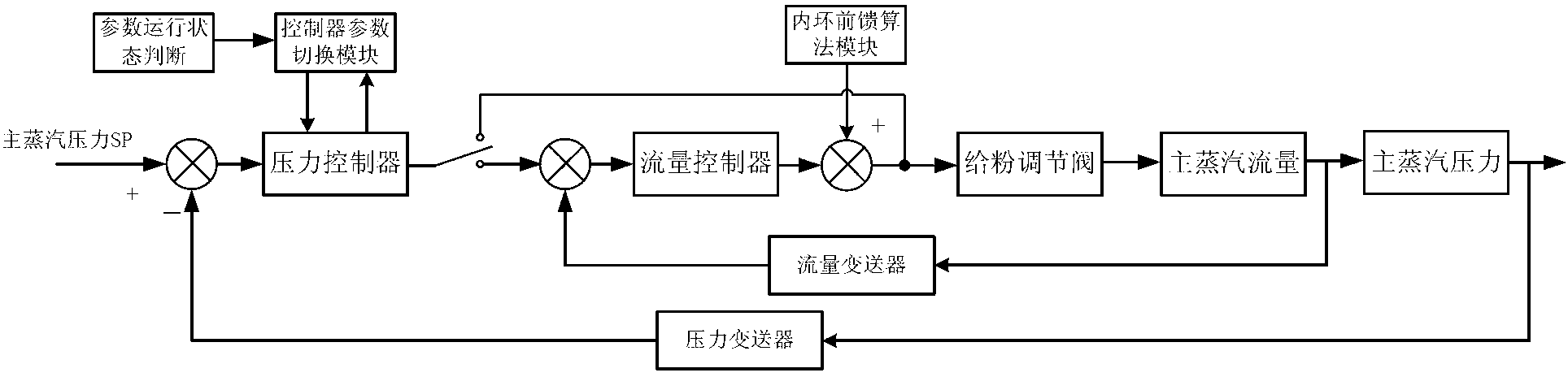

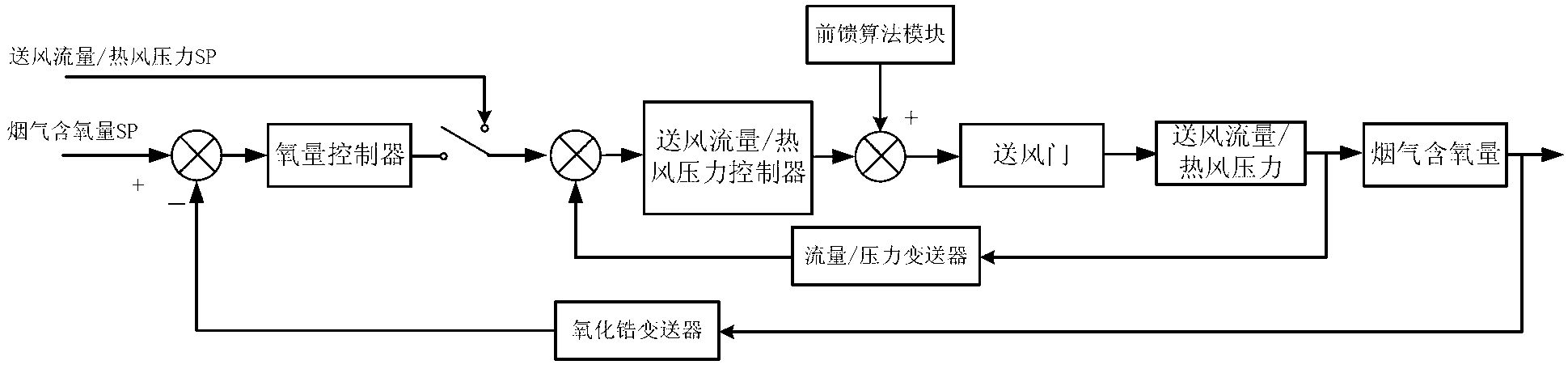

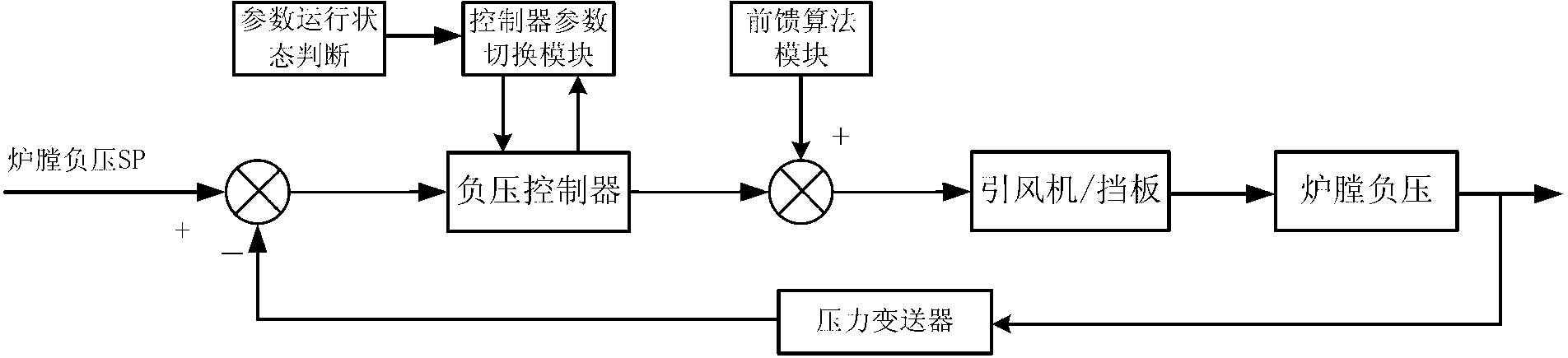

[0039](1) The control strategy combining conventional control and advanced control is adopted to realize the automatic control of boiler main steam pressure (or flow), main steam temperature, flue gas oxygen content, furnace negative pressure, and steam drum water level, so as to ensure boiler control and Stability of the combustion optimization system;

[0040] (2) Taking the boiler efficiency as the optimization target, real-time optimization of the operating parameters during the boiler combustion process is carried out to ensure that the system operates in the best combustion zone;

[0041] (3) Add a control and optimization station to the monitoring layer of the distributed control system to realize online calculation of boiler efficiency, control algorithm, combustion optimization algorithm, and fault diagnosis of boiler control and combustion optimization process.

[0042] The application method of the boiler co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com