Blade of direct-current electric gasoline pump

A fuel pump, direct current technology, applied to pumps, rotary piston type/oscillating piston type pump components, pump components, etc., can solve problems such as rapid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

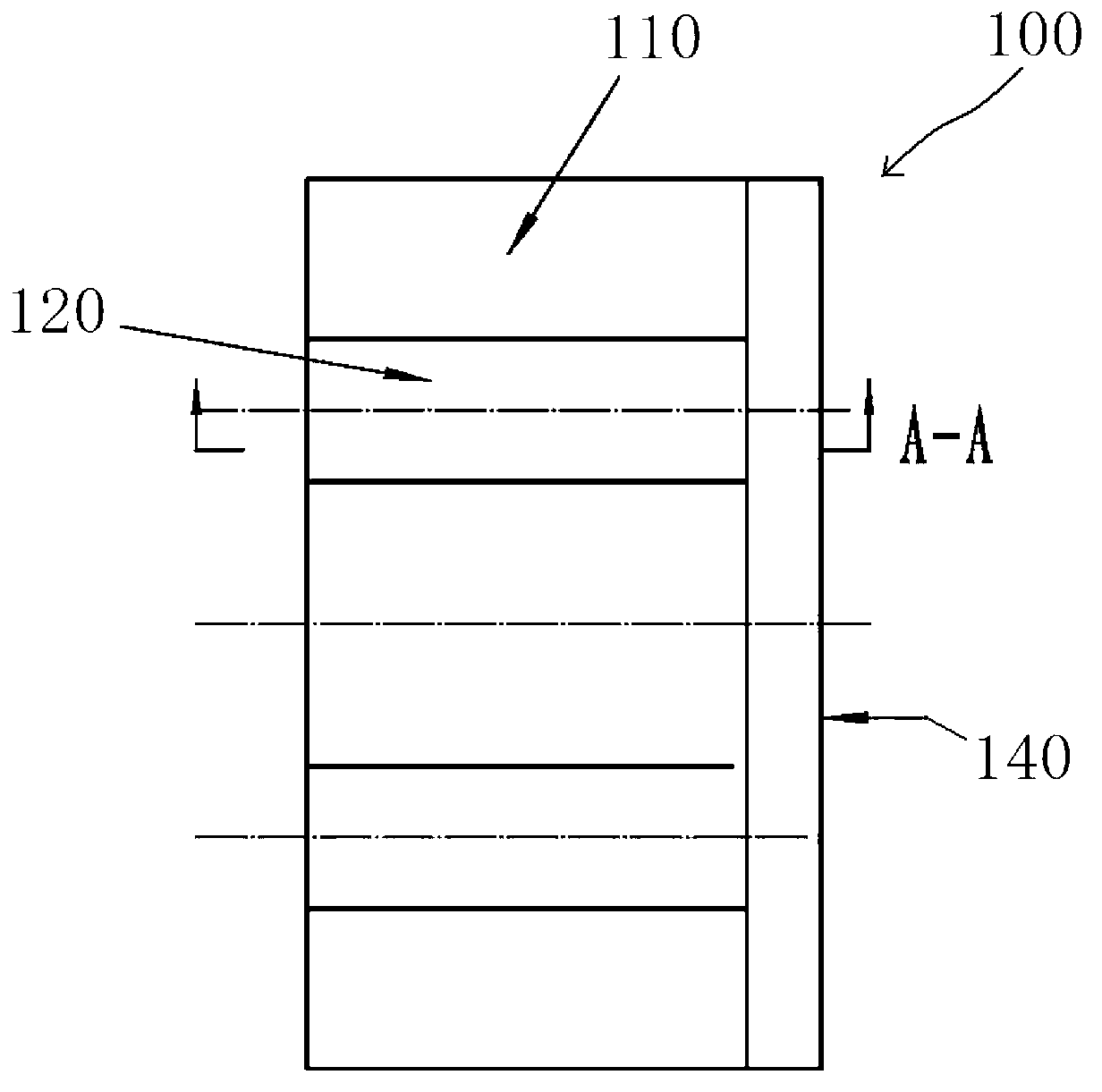

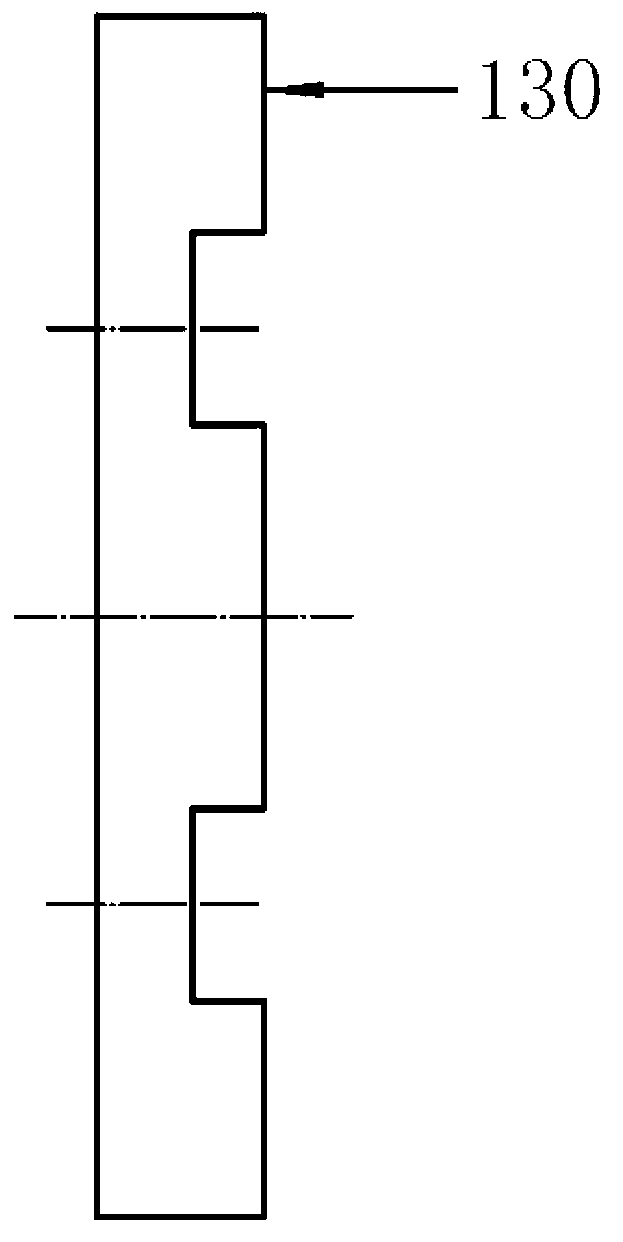

[0016] see Figure 2 to Figure 4 , the vane 100 of a DC electric fuel pump shown in the figure is a cuboid structure, the front side 130 of the cuboid structure is arranged with ribs 110 at intervals, and oil drain grooves 120 are arranged between the ribs 110 . The thickness A1 of the cuboid structure is greater than 1 mm, and the distance B1 between the top of the rib 110 and the top 140 of the cuboid structure is greater than 1 mm.

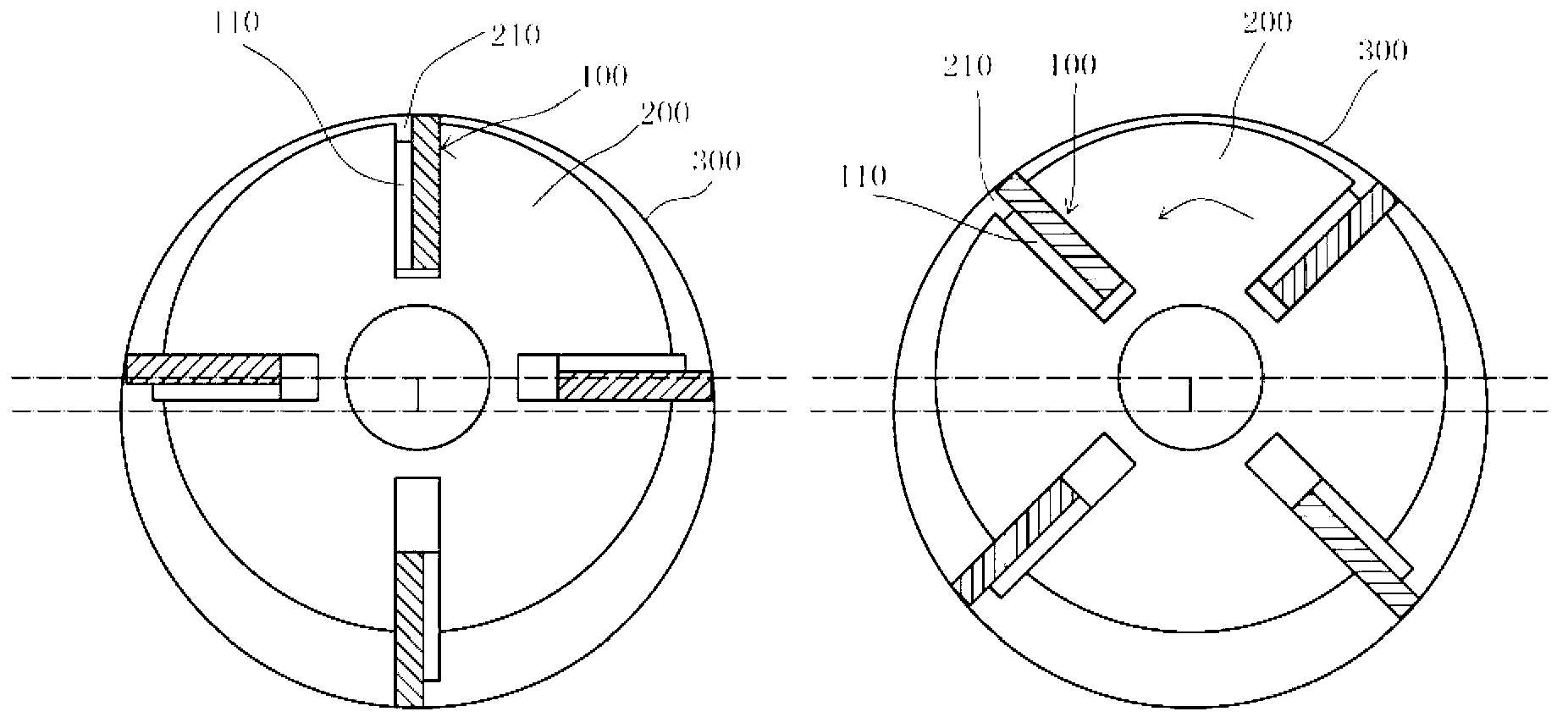

[0017] see figure 1 , the vane 100 is disposed in the slot 210 of the vane pump rotor 200 , and the vane 100 can reciprocate in the slot 210 . When the rotor 200 rotates, the blade 100 is always in contact with the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com