Pendulum slide pump

A pendulum type and hammer type technology, applied in the field of inner rotor, can solve the problem of high stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

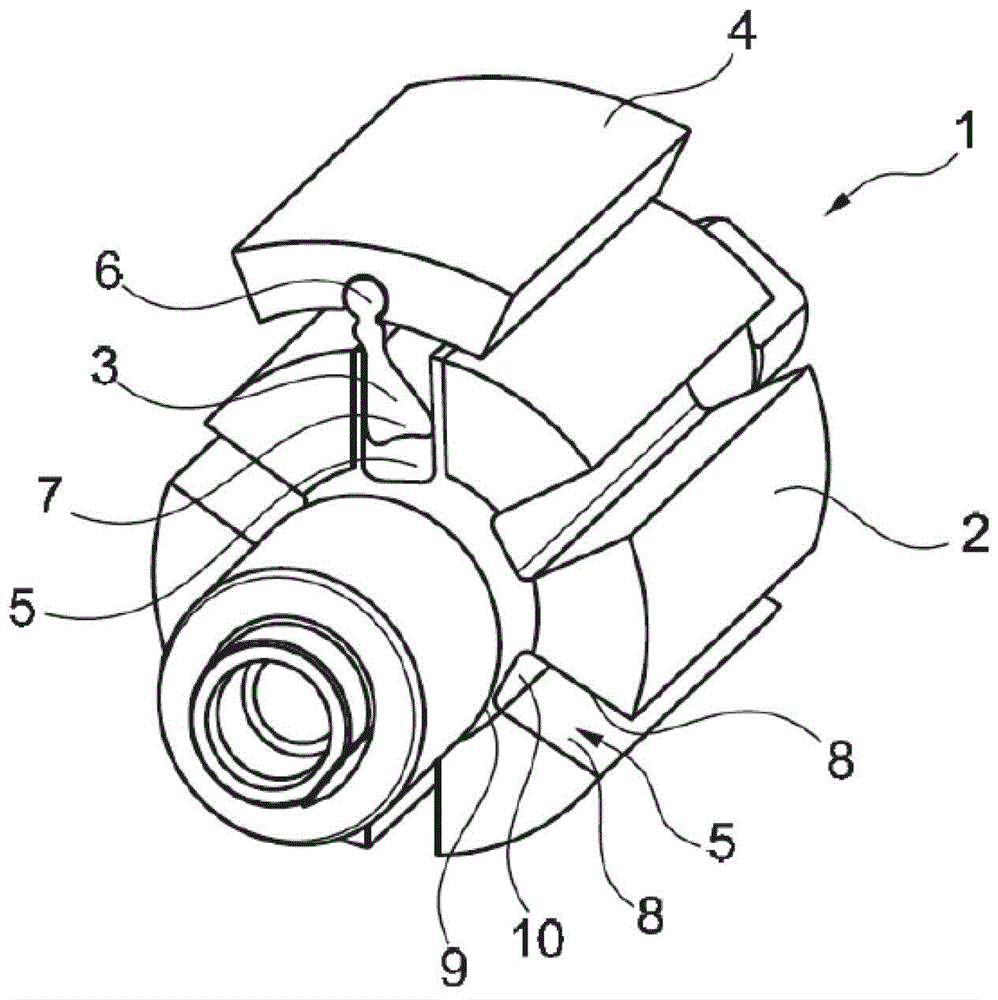

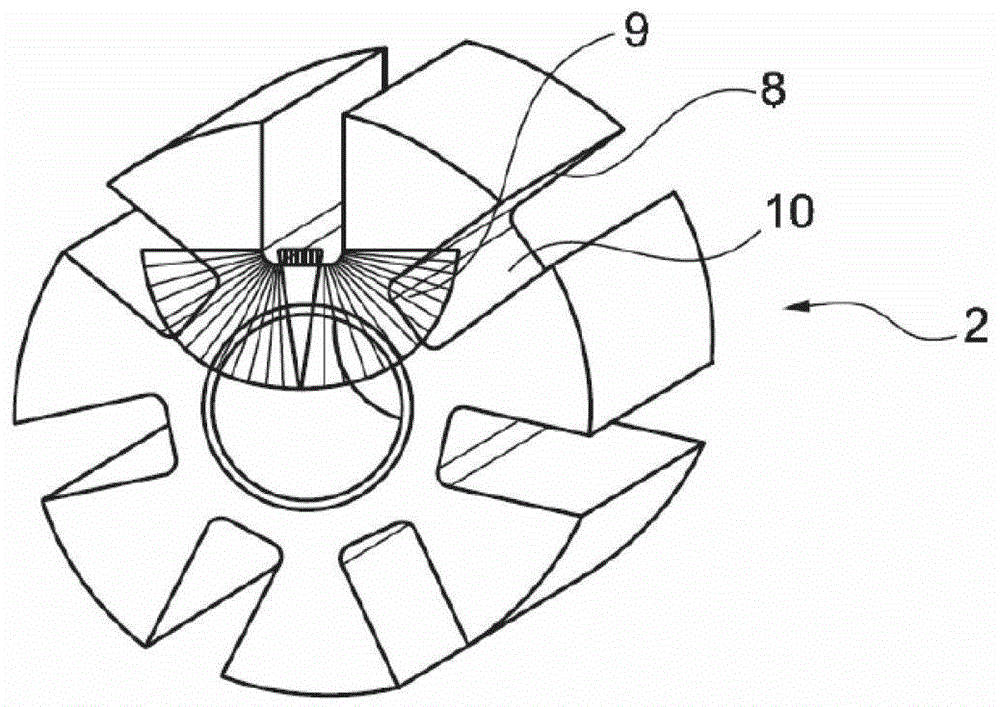

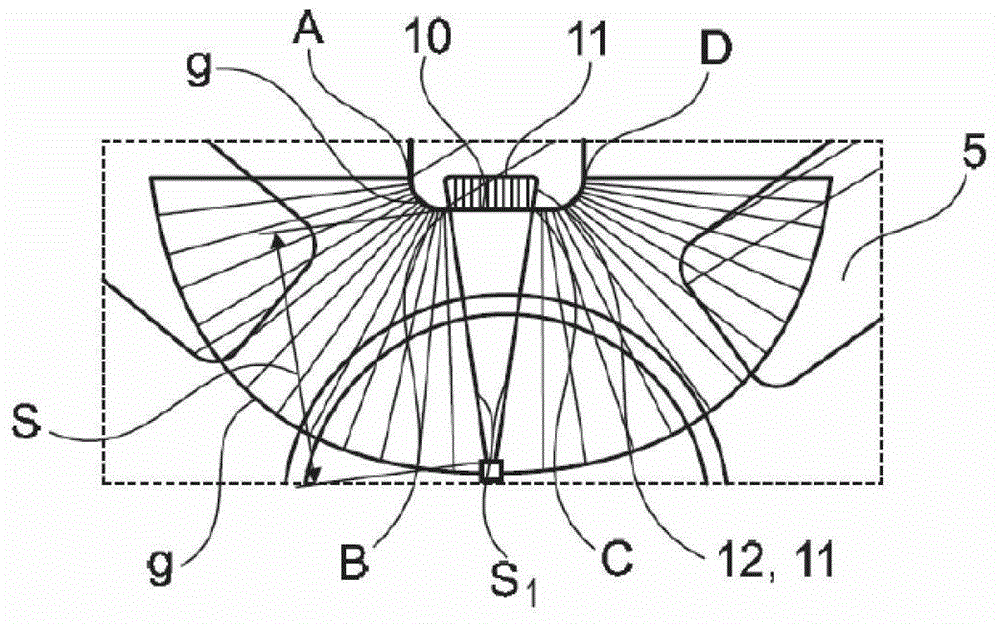

[0021] according to figure 1 , the pendulum-type sliding pump 1 according to the invention has a rotatably mounted inner rotor 2 which is connected to an outer rotor 4 via a pendulum 3 . For the sake of simplicity, only the sheared part of the outer rotor 4 and a single pendulum 3 are shown. The illustrated pendulum 3 is articulatedly mounted on the outer rotor 4 and is guided radially in an associated groove 5 of the inner rotor 2 . Generally, the pendulum 3 is composed of a pendulum head 6 and a pendulum leg 7, wherein the pendulum head 6 is rotatably mounted on the outer rotor 4, and the pendulum leg 7 is installed so as to be able to fit inside the groove 5 of the inner rotor 2. Move in translation. Of course, the opposite embodiment is also conceivable, in which the pendulum head 6 of the pendulum 3 is mounted in rotation on the inner rotor 2 and the pendulum legs 7 are able to move in a translational manner in grooves arranged on the outer rotor 4 move. The inner rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com