Three-cylinder direct-current miniature pump

A technology of micro-pumps and cylinders, which is applied to pumps, pumps with flexible working elements, liquid variable capacity machines, etc. It can solve the problems of unsatisfactory impact resistance and elasticity, affect the normal operation of motors, and limit the application of micro-pumps, etc., and achieve compact structure , low cost, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

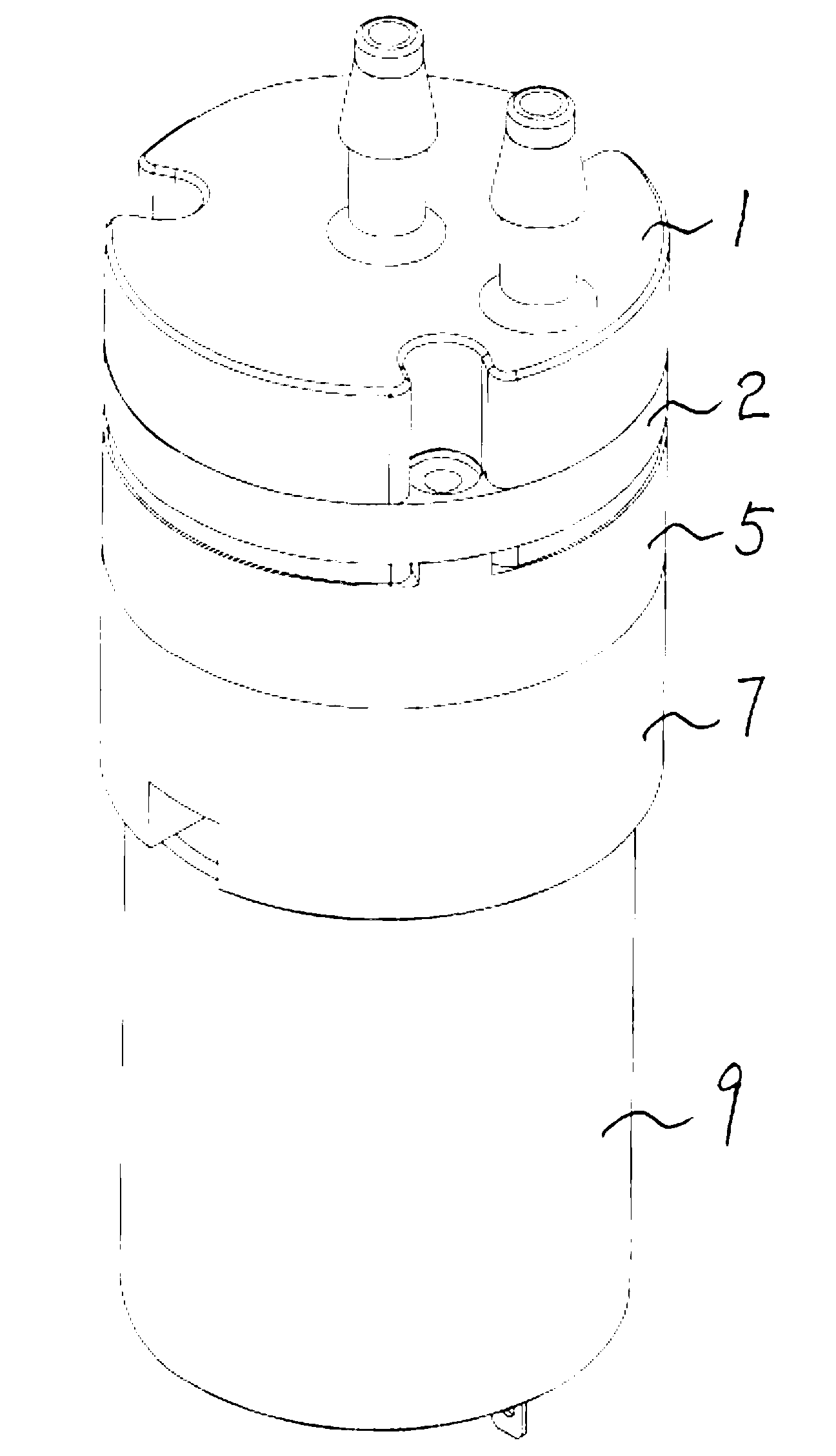

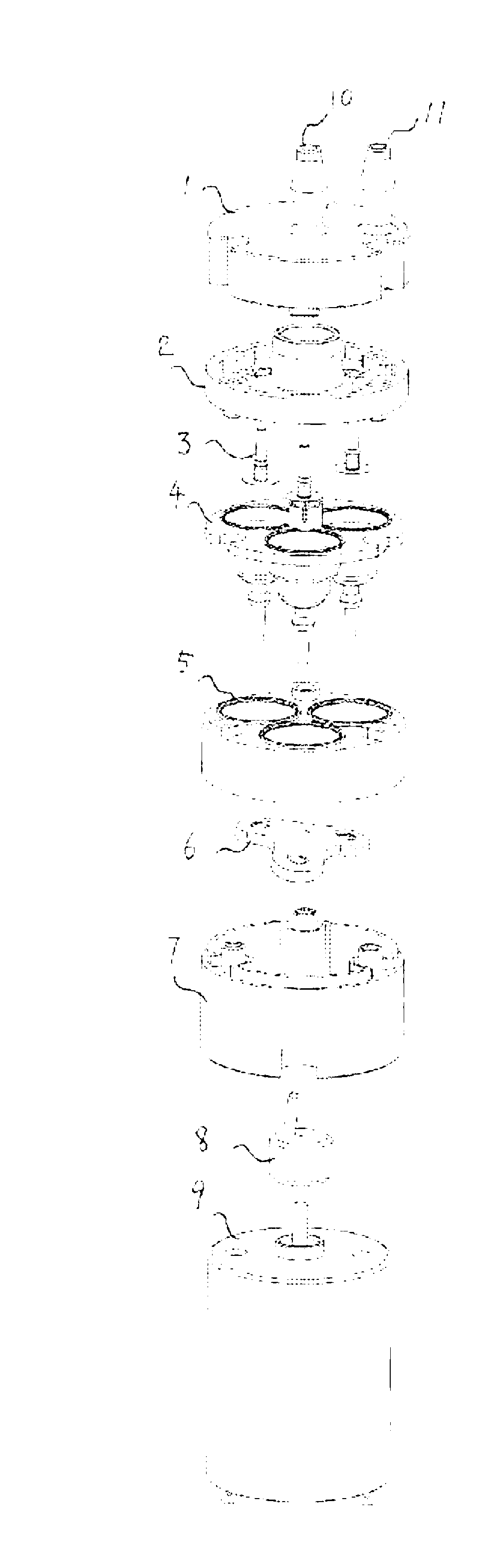

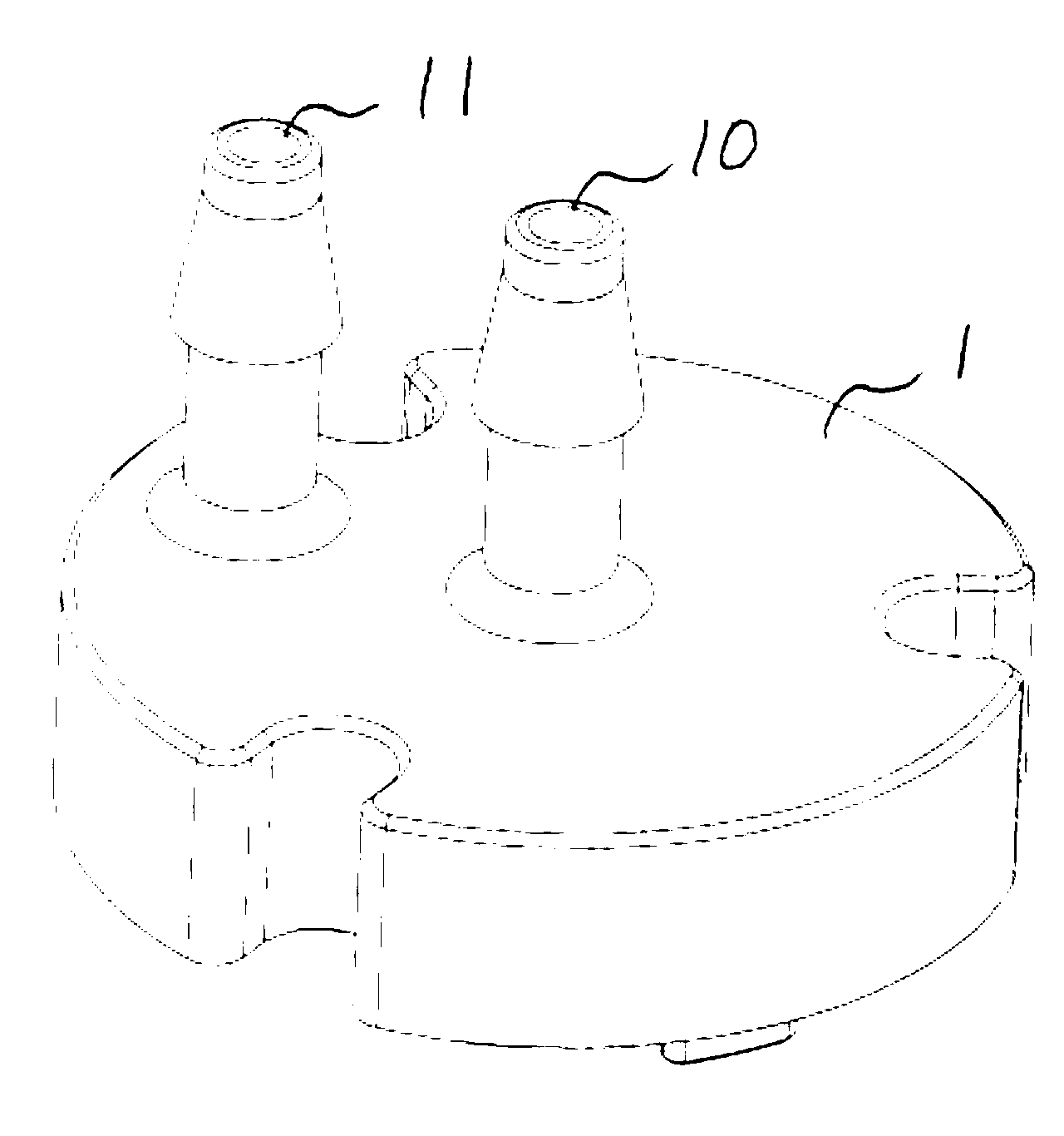

[0034] Such as Figures 1 to 12 , a three-cylinder DC micro-pump is characterized in that it includes a sound-absorbing cover 1, an upper cover 2, an umbrella head 3, a cylinder 4, a middle cover 5, an eccentric frame 6, a lower cover 7, an eccentric seat assembly 8 and a drive motor 9, The muffler cover 1, upper cover 2, middle cover 5, lower cover 7 and drive motor 9 are sequentially connected from top to bottom, the eccentric seat assembly 8 is connected to the output shaft of the drive motor 9, and the eccentric seat assembly 8 is connected to the eccentric frame 6 connection, the eccentric seat assembly 8 and the eccentric frame 6 are set in the lower cover 7, the eccentric frame 6 is connected with the cylinder 4, the cylinder 4 is set in the middle cover 5, the upper cover 2 is set above the cylinder 4, and the umbrella head 3 is fixed on the upper cover 2 Above, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com