A hole box type floating breakwater with built-in buoyancy unit

A floating breakwater and buoyancy unit technology, applied in the directions of breakwaters, embankments, jetties, etc., can solve the problems of incompatible distribution rules, water circulation restrictions, water pollution in the port, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

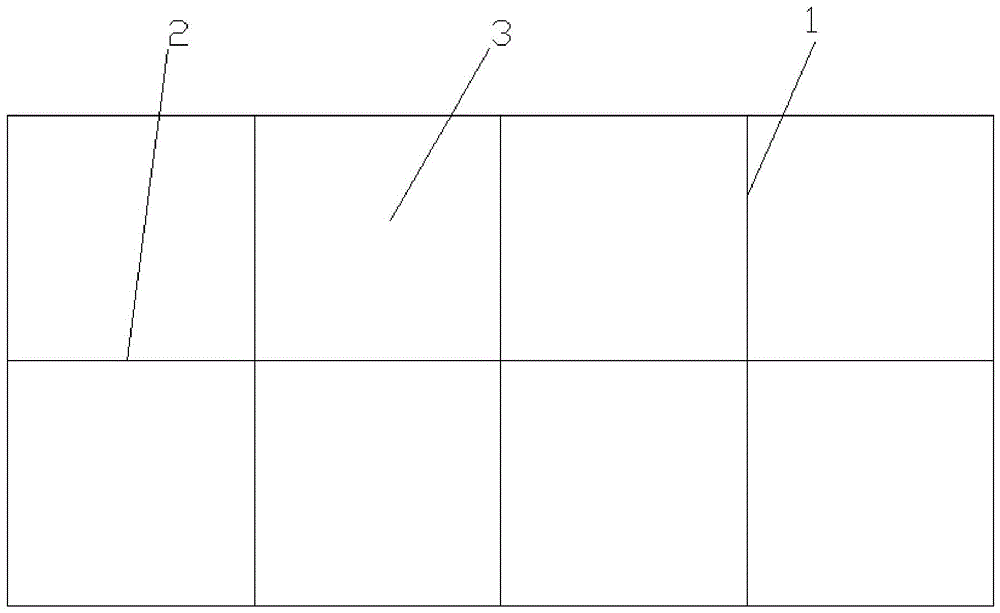

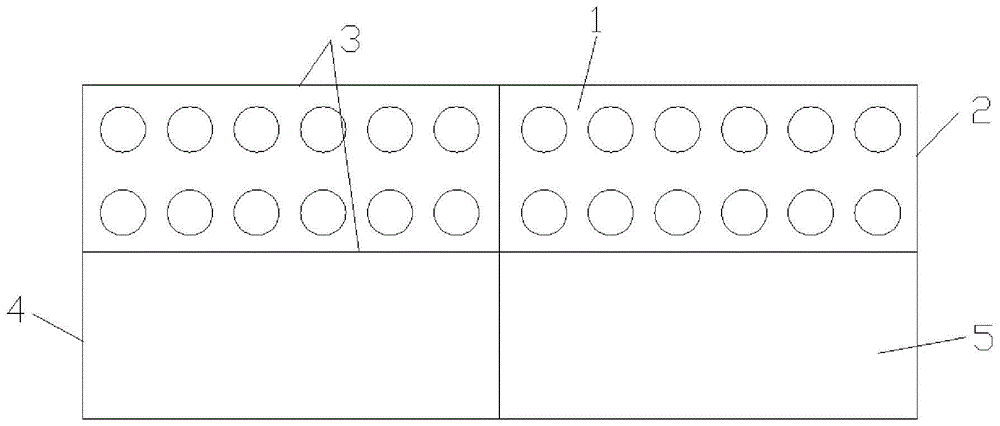

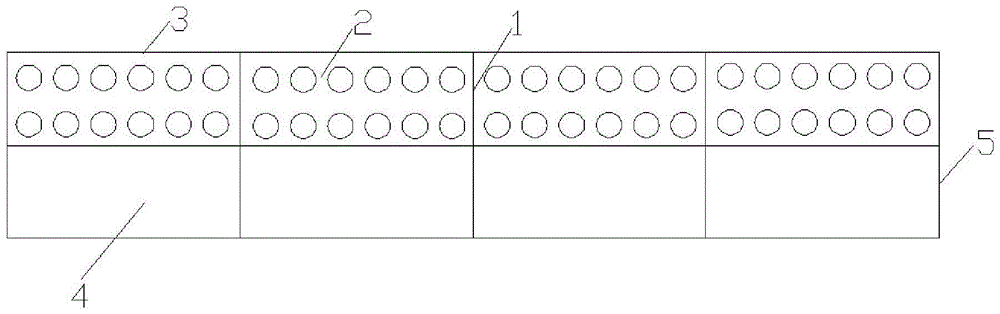

[0026] Such as Figure 1 to Figure 8 As shown, a perforated box-type floating breakwater with a built-in buoyancy unit of the present invention includes an open-hole box structure, a buoyancy unit and an anchoring device; the buoyancy unit is placed inside the open-hole box structure, and the anchoring device is symmetrically arranged on On both sides of the open-hole box structure; the open-hole box structure includes a number of porous rigid plates, a number of rigid plates and a number of rigid support columns 6, and the porous rigid plates and rigid plates are vertically arranged in pairs and rigidly connected to form an open-hole box body structure, the rigid support columns 6 are installed in parallel at the bottom of the perforated box structure; the upper half of the perforated box structure is located on the waterline, and the lower half is located below the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com