Assembling method of quayside with low posture

An assembly method and low-profile technology, applied in the directions of transportation and packaging, walking bridge cranes, cranes, etc., can solve the problems of reducing the overall height of the quay crane, unable to use the conventional quay crane assembly technology for assembly, etc., to ensure the installation size, The effect of reducing high-altitude boring operations and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

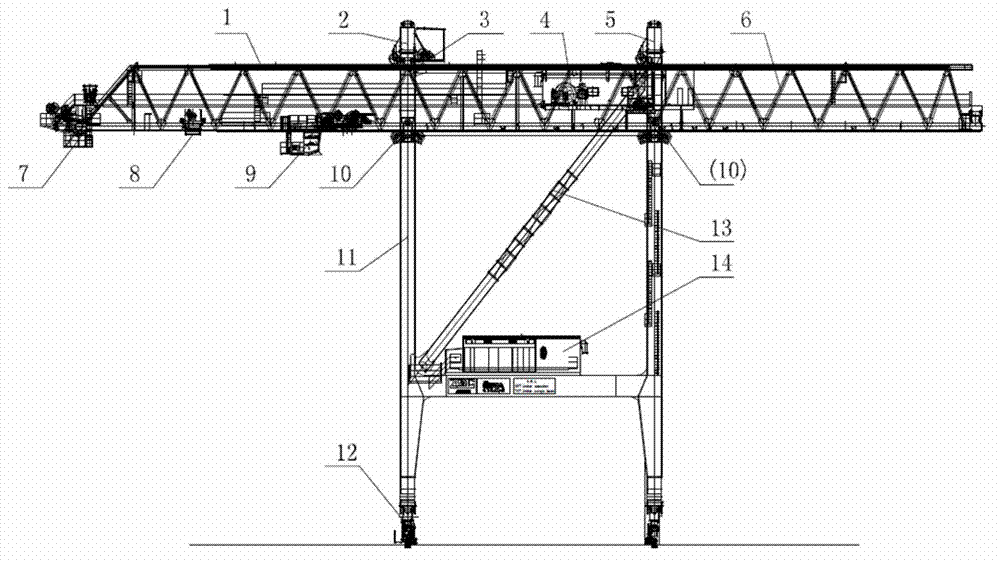

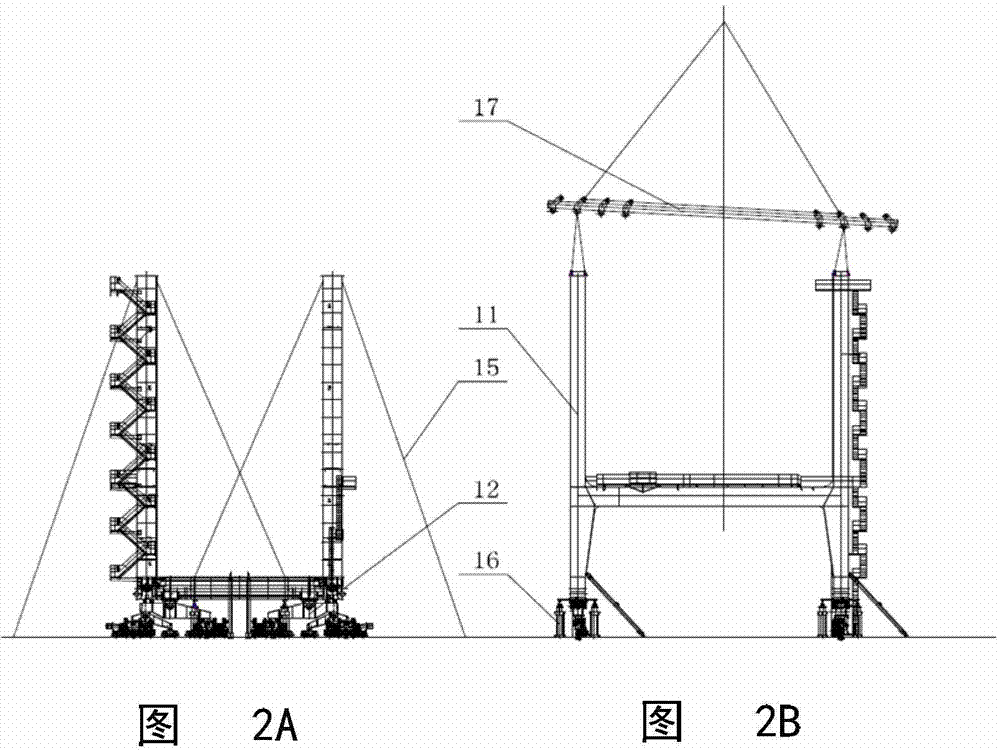

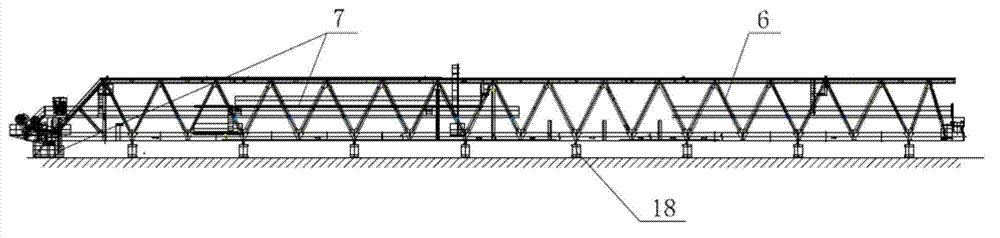

[0057] figure 1 A general structural diagram of the low-profile quay bridge according to the present invention is shown. like figure 1 As mentioned above, the entire low-profile quay bridge is mainly composed of main components such as the traveling mechanism of the cart, the door frame structure, the truss type girder, the suspension device, the three major driving and winding systems, the electrical system, the trolley and the trolley structure of the land side bracket, and the ladder platform. .

[0058] The truss-type girder has four welded rails and two trolley rails, which are supported by the suspension device, and the driving mechanism is used to make it run in the direction of sea and land, reducing the overall height. The conventional quay crane has only one machine room, but this quay crane preferably has three machine rooms, namely: the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com