Handle folding device of double line plastic bag folding machine

A technology of folding device and plastic bag, applied in the direction of folding thin materials, thin material handling, transportation and packaging, etc., can solve the problems of occupying a large workshop space, increasing manufacturing costs, unstable machines, etc., and achieving a small occupied workshop area and saving The effect of manufacturing cost, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

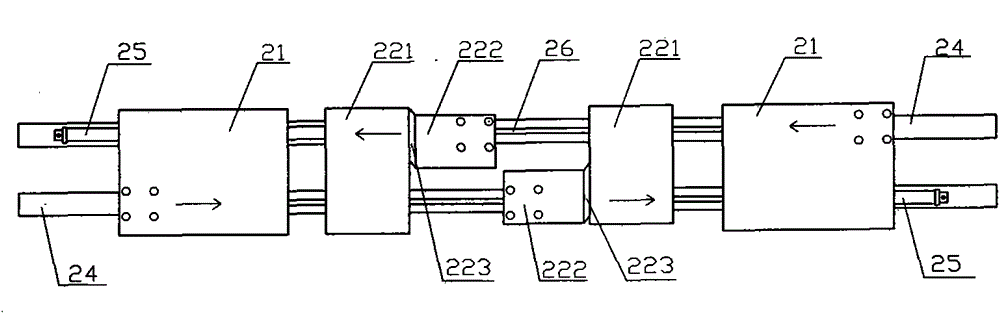

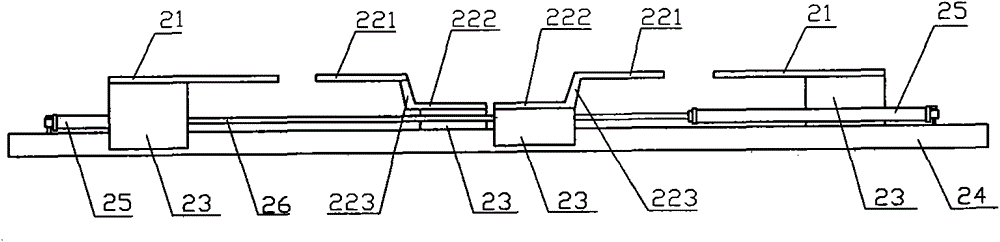

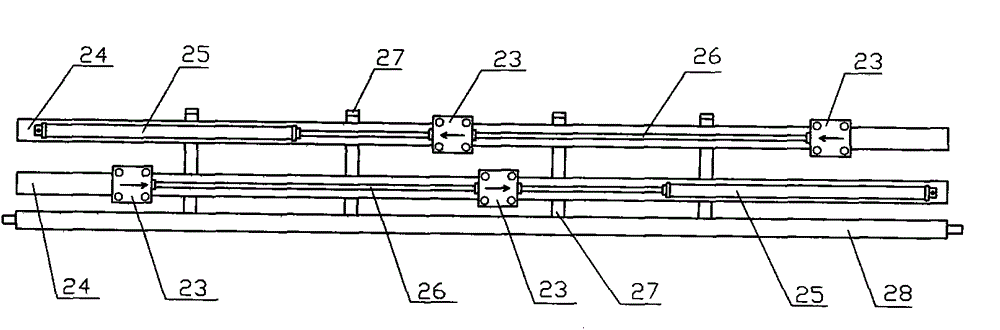

[0021] Below in conjunction with accompanying drawing, further elaborate the present invention. Such as Image 6 As shown, the handle folding device of the double-line plastic bag folding machine includes a frame 1, on which the supporting plate turning shaft 28 is rotated and installed, and one end of the supporting plate turning shaft 28 is connected with the turning shaft driving device 2; A bracket 27 is installed on the shaft 2, and two linear guide rails 24 are installed in parallel on the bracket 27; two sliding bodies 23 are respectively installed on each guide rail, and the two sliding bodies 23 are connected by a connecting rod 26, and one of the sliding bodies 23 is connected Cylinder 25, the afterbody of cylinder 25 is installed on the carriage 27; In two sliding bodies 23 on every linear guide rail, a handle folding push plate 21 is installed on one sliding body 23, and a handle folding push plate 21 is installed on the other sliding body 23 Staggered hidden tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com