Assembling fixture for water cutter decoration bar

A technology for decorative strips and jigs, which is applied in the field of assembly jigs for water-cut trim strips. It can solve the problems of missing end caps, low assembly efficiency, and no prompts on whether the end caps are installed, so as to achieve smooth assembly of buckles and improve assembly efficiency. , to avoid the effect of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

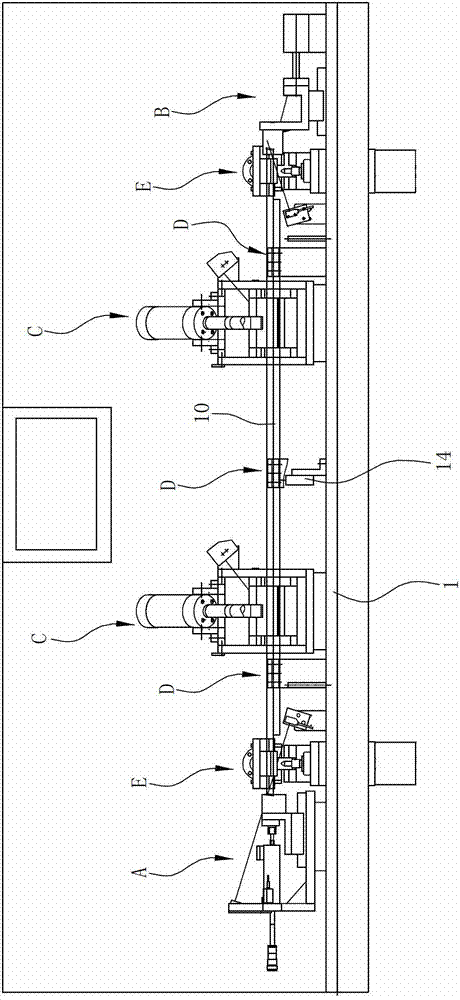

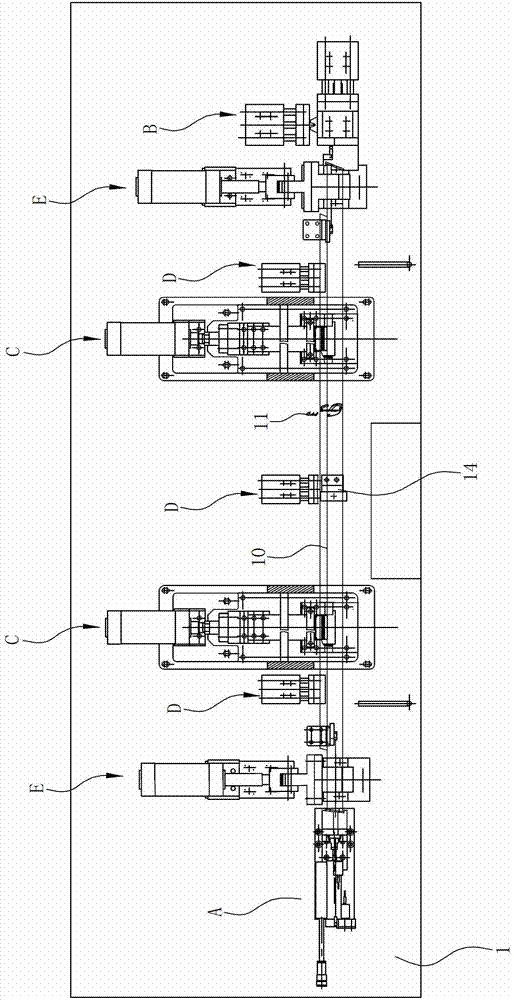

[0042] like Figure 1-21 Shown is a preferred embodiment of the present invention.

[0043] A water-cut decorative strip assembly jig, including a left end cover detection and assembly device A located at the left and right ends for installing the left end cover 10a on the water-cut decorative strip 10, and for installing the right end cover 10b on the water-cut decorative strip 10. The right side end cover detection assembly device B on the water-cut trim 10, and multiple snap-fit assembly devices C and multiple pusher devices D located in the middle.

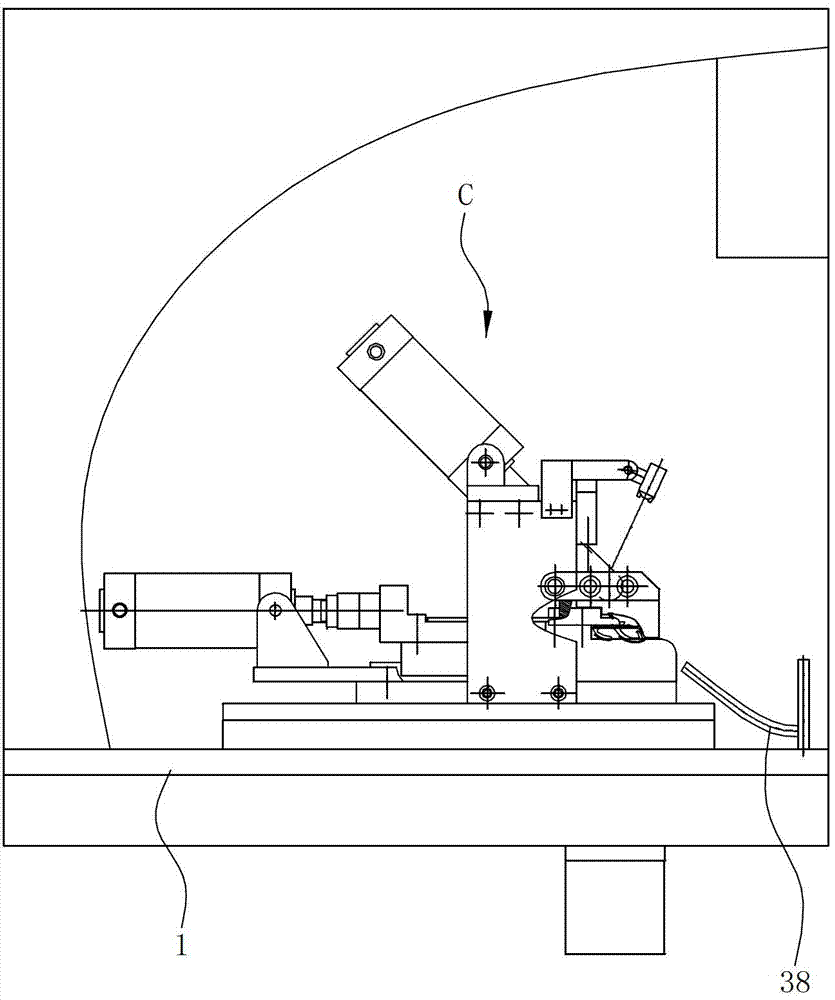

[0044] like Figure 15-20 As shown, the buckle assembly device C includes a spacer 2 fixed on the frame platen 1. The spacer 2 is in the shape of a ladder. Two inserts 3 are fixed on the front and rear sides of the top of the spacer 2. The two inserts 3 The top of the spacer is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com