RFID-based automatic time optimization method for work piece in production line

A workpiece and time technology, applied in computer parts, instruments, induction record carriers, etc., can solve problems such as heavy workload, inability to accurately calculate production efficiency, affecting production line work efficiency and process management, etc., to improve production efficiency and improve automation. The effect of data collection management level

Inactive Publication Date: 2013-09-18

SHANGHAI AVANT PORT INFORMATION TECH

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, one of the disadvantages of this method is that the employees must collect all the work tickets at the end of a specific fixed period according to the week or month or a fixed period of time, and the work recorded by the factory through these work tickets data to account for their salaries and other expenses

These have affected the work efficiency of the production line and the management of the process.

In addition, the existing production line cannot provide real-time status information of all the workpieces currently being produced, as well as other data in various processes, resulting in the inability to monitor the production status, manage the production process, and identify production bottlenecks and effectively monitor them. Targeted process adjustment and redeployment, let alone accurate calculation of current production efficiency

Moreover, in the process of calculating employee salaries and other expenses, it is necessary to process a large number of invoices provided by employees, which is a rather heavy work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

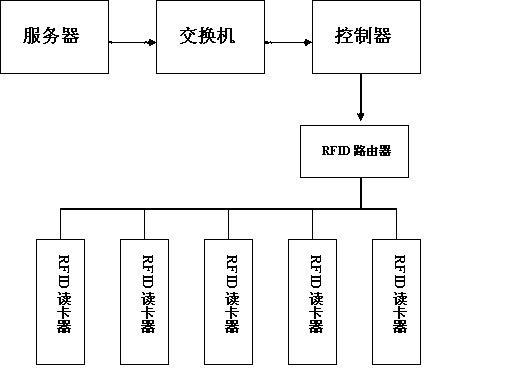

The invention discloses an RFID-based automatic time optimization method for a work piece in a production line. The method comprises the following steps: a worker users a card reader corresponding to a distributed operating post thereof to read an employee identity radio frequency identification card; the worker puts a work piece radio frequency identification card distributed on a work piece in a reading range of the card reader before a distributed work piece is processed and takes the work piece radio frequency identification card out of the reading range of the card reader after processing is finished; information in the employee identity radio frequency identification card and the work piece radio frequency identification card is read by the card reader and sent to a server; and the server calculates an average processing time used as a standard completion time for the work piece according to statistical analysis on time for different workers to process the work piece. The RFID-based automatic time optimization method can be used for scientifically determining the best production time of the work piece so as to provide a reference basis for effective improvement of the management level of the production line.

Description

technical field [0001] The invention relates to an automatic measurement method, in particular to an RFID-based automatic optimization method for workpiece time in a production line. Background technique [0002] In the current large-scale industrial production, especially in the manufacturing process, there are many problems such as inaccurate collection of production data and difficult management of the process. For example, in garment production operations, at present, garment workers still generally use a work ticket bound on the cut semi-finished product workpiece to record production data. Those job descriptions related to the production process, as well as other information, are pre-printed on these work tickets, which are then performed on multiple workstations after a specific part of the work or task is completed, cut by the employee performing the work or task and Sign your name. However, one of the disadvantages of this method is that the employees must colle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06Q50/04G06K7/00

CPCY02P90/30

Inventor 周志勇

Owner SHANGHAI AVANT PORT INFORMATION TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com