Active or passive combined acoustic testing and seepage testing combined system for rock triaxial test

A technology of triaxial test and acoustic test, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc., can solve the problems of high cost and accuracy, and achieve guaranteed accuracy, low cost, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

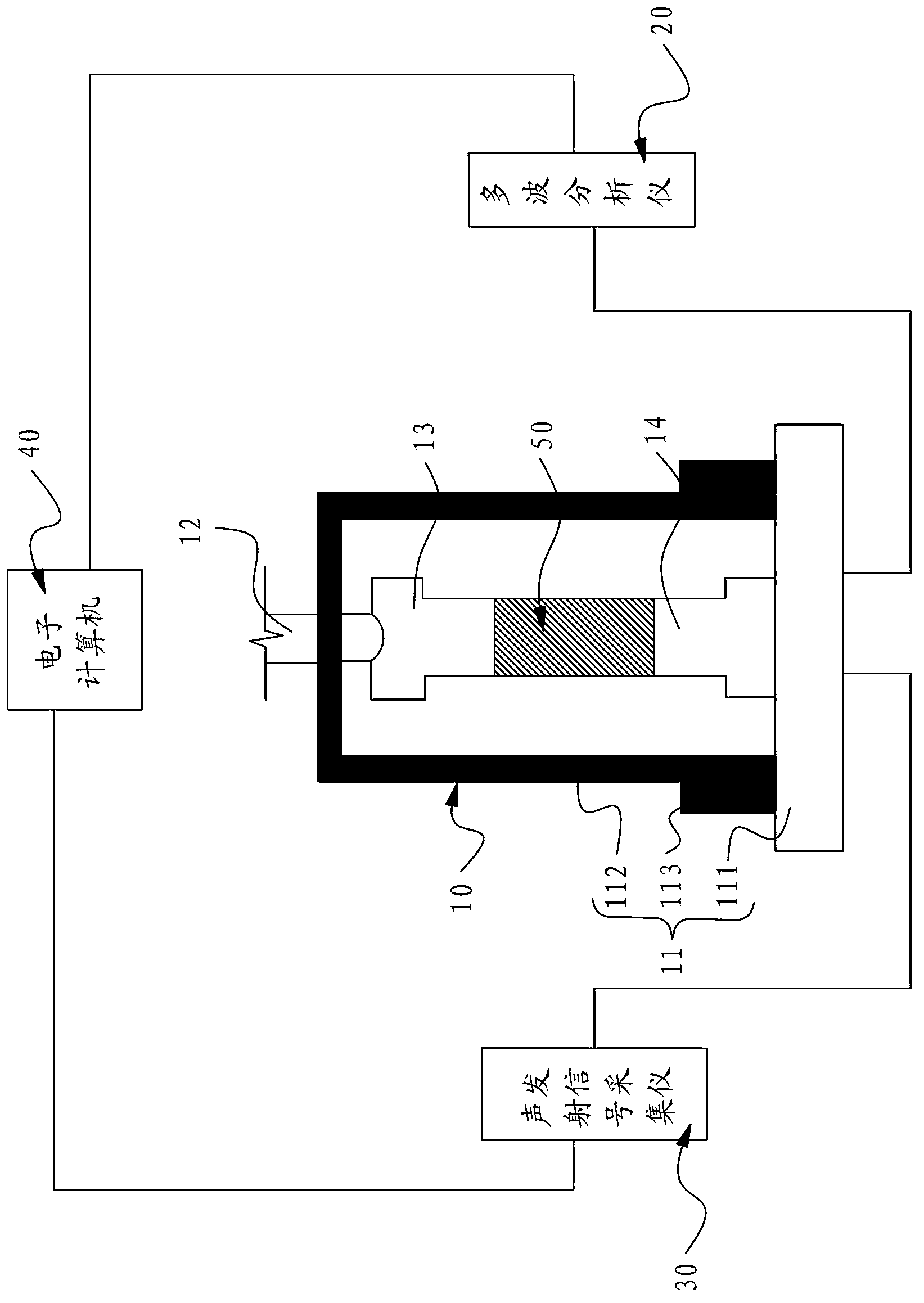

[0048] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a rock triaxial testing machine 10 , a multiwave analyzer 20 , an acoustic emission signal acquisition instrument 30 and an electronic computer 40 .

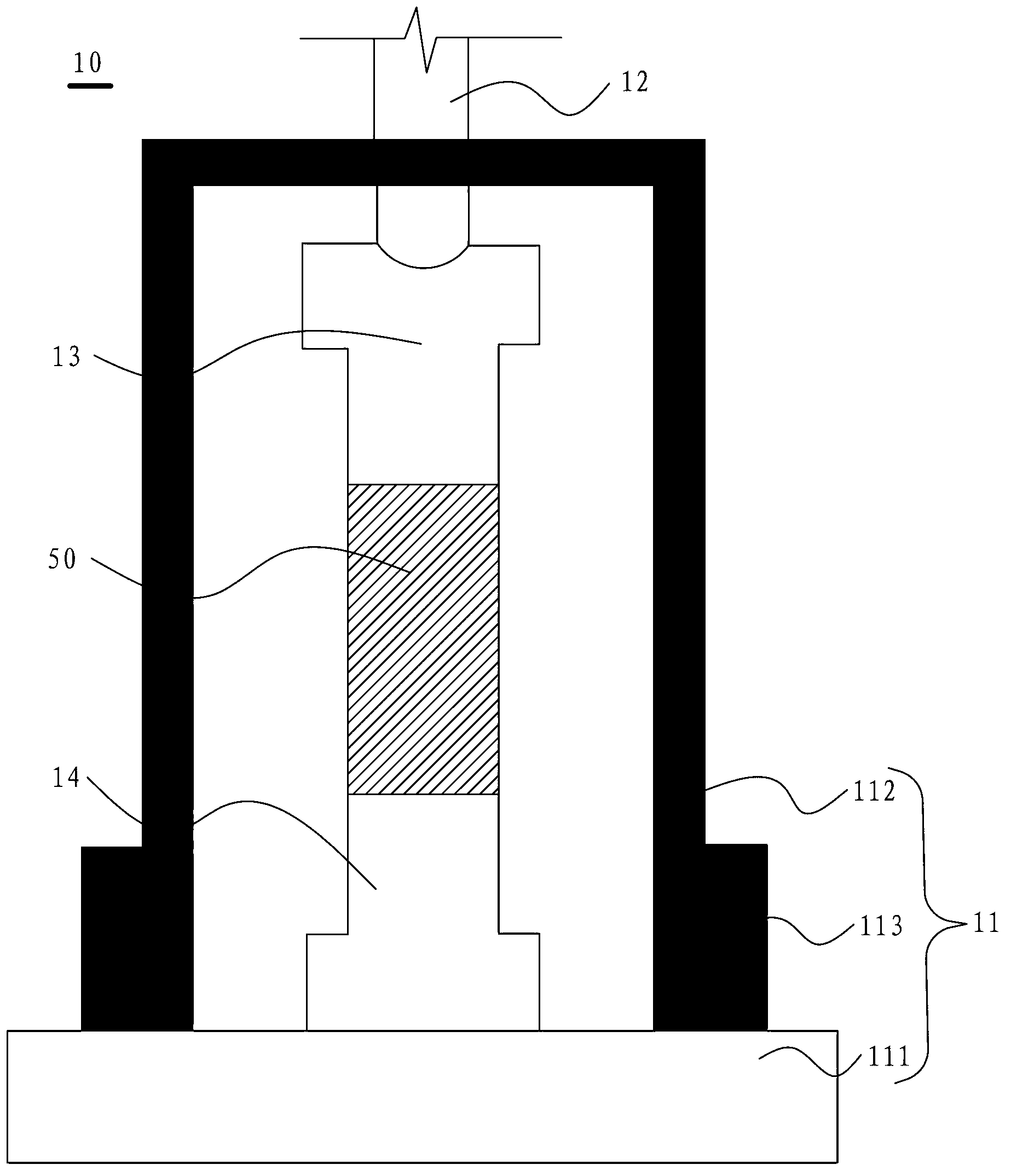

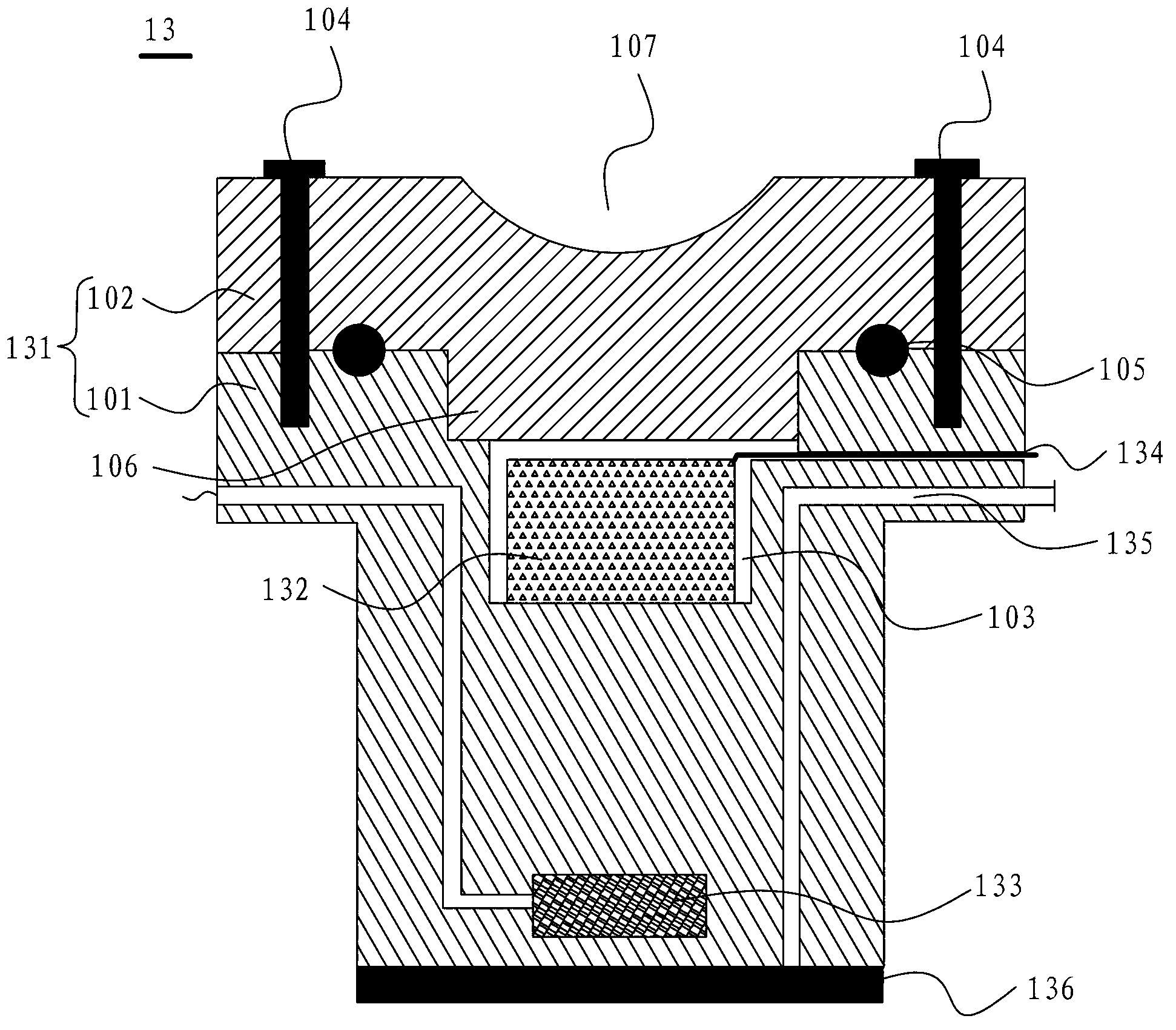

[0049] Wherein, the rock triaxial testing machine 10 includes a sealed pressure chamber 11, an axial pressure guide rod 12, and an upper pressure-bearing probe 13 and a lower pressure-bearing probe 14 arranged in the sealed pressure chamber 11 for clamping the rock sample 50; The multiwave analyzer 20 , the acoustic emission signal acquisition instrument 30 and the electronic computer 40 are located outside the sealed pressure chamber 11 .

[0050]Specifically, in this embodiment, the sealed pressure chamber 11 includes a base 111 and a main body cover 112, the main body cover 112 is fixed on the base 111, and the outside of the joint between the main body cover 112 and the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com