Double-layer bidirectional pre-tensioned track plate

A track board, double-layer technology, applied in the field of track boards, can solve the problems of increasing the number of board factories and labor costs, low production efficiency, and no independent intellectual property rights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

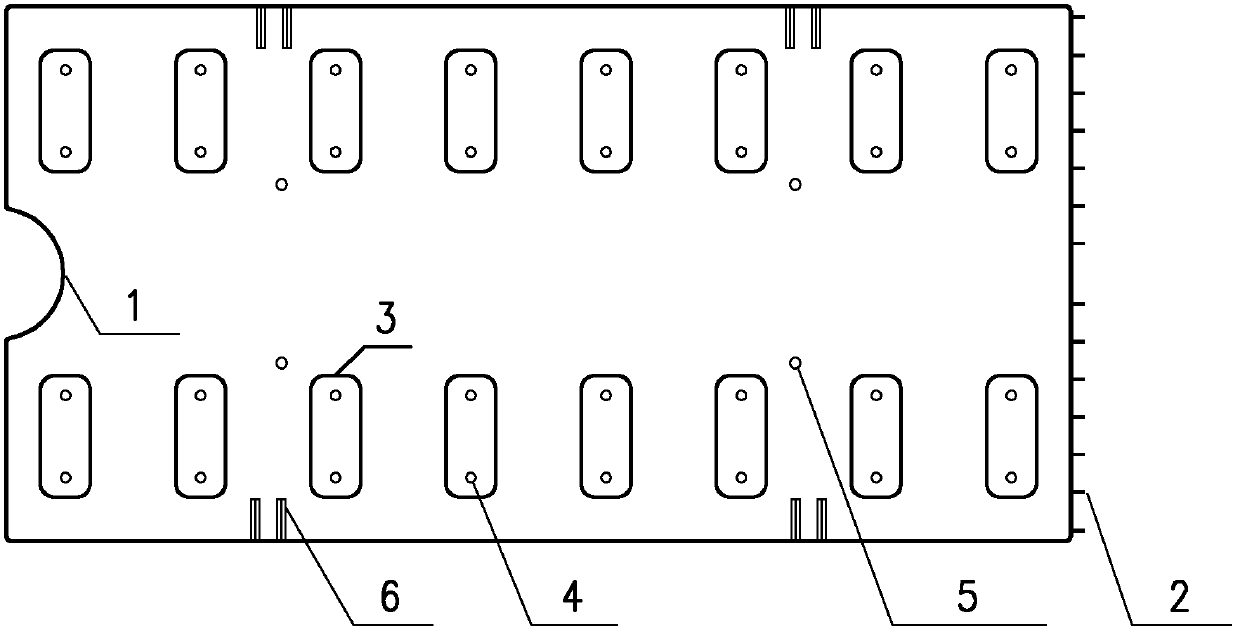

[0069] Such as Figure 1 ~ Figure 3 As shown, the CRTS I-type track plate includes a concave limit groove 1, and the concave limit groove 1 is located at one end of the CRTS I-type track plate in the length direction, and is used for cooperating with the convex block to limit the position; the CRTS I-type track plate The other end in the length direction is provided with a longitudinal connector 2, which is used for the connection of two adjacent CRTS I-type track slabs. Above the CRTS I-type track slab, there are two rows of parallel rail bottoms 3, and the rail bottoms 3 are embedded The bushing 4 is fixedly connected to the CRTS I-type track slab, and there is a mortar pouring hole 5 above the CRTS I-type track slab, and there are lifting sleeves 6 on both sides of the CRTS I-type track slab for the laying and installation of the CRTS I-type track slab;

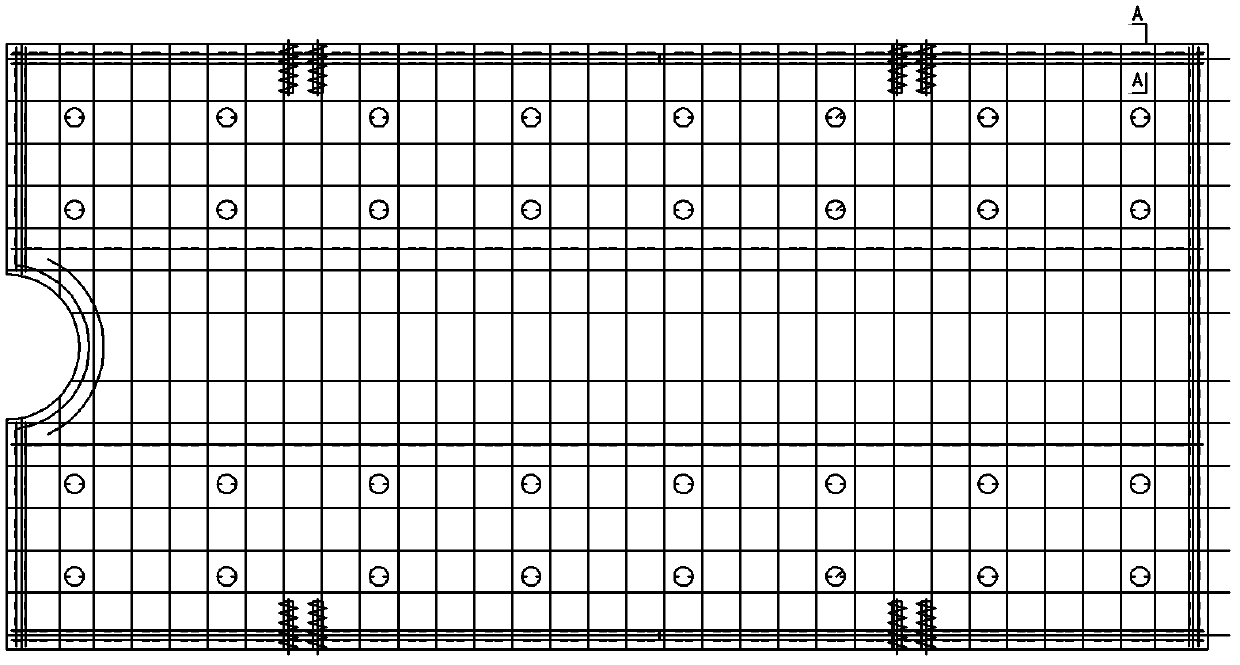

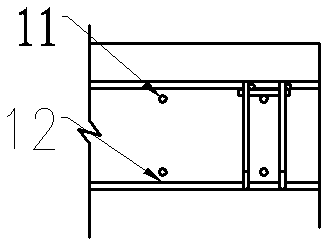

[0070] A layer of transverse prestressed reinforcement group 12 and a layer of longitudinal prestressed reinforcement gr...

Embodiment 2

[0073] The specific implementation of embodiment 2 is the same as that of embodiment 1, the difference is that embodiment 2 adopts CRTS II track slabs, and a layer of transverse prestressed steel bar group 12 and a layer of longitudinal Prestressed reinforcement group 11; longitudinal prestressed reinforcement group 11 is distributed in the same horizontal plane of CRTS II type track slab; transverse prestressed reinforcement group 12 is distributed in the same horizontal plane of CRTS II type track slab; The distance between the longitudinal prestressed reinforcement group 11 and the transverse prestressed reinforcement group 12 is not less than 6 mm; two vertical stirrups are respectively arranged in the prestressed reinforcement anchorage area around the CRTS II track slab. The middle part is longitudinally symmetrical along the track slab, and there is also a vertical stirrup in the center of the slab, and an insulating layer is provided outside the six vertical stirrups, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com