Tire tread rubber without zinc oxide

A tire tread and zinc oxide technology, applied in the field of zinc oxide-free tire tread rubber, can solve water pollution and other problems, and achieve the effects of avoiding pollution, good performance, and promoting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

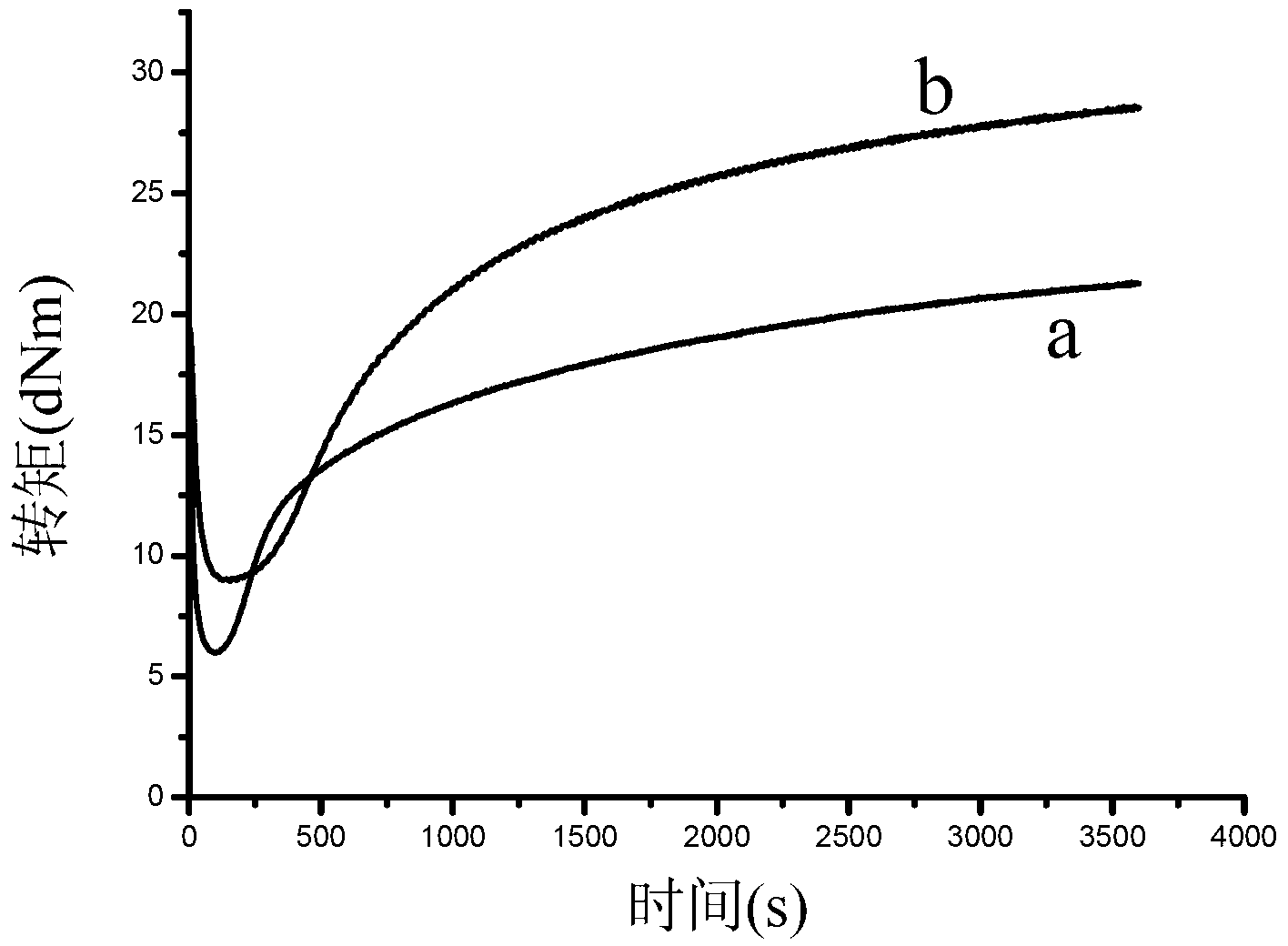

[0028] According to the formula in Table 1, the amount of styrene-butadiene rubber 1502 is 100 parts, the amount of carbon black N330 is 30 parts, the amount of zinc oxide is 0 parts, and the amount of cetyltrimethylammonium chloride is 2 parts. Mixing, the mixing temperature is 50 ° C, The vulcanization temperature is 150°C, and the vulcanization time is 1h. Then test the vulcanization performance of the compound at 150°C. The vulcanization curve of the sample at 150°C is as follows figure 1 As shown in the middle curve (a), the 150°C vulcanization curve of the reference sample is as follows figure 1 Curve (b) in the middle; the vulcanization properties and physical and mechanical properties of the vulcanizate are shown in Table 2.

[0029] Table 2 Effect of quaternary ammonium salts on properties of styrene-butadiene rubber

[0030]

[0031] As can be seen from the results in Table 2: compared with the reference sample, T containing 2 parts of quaternary ammonium salt ...

Embodiment 2

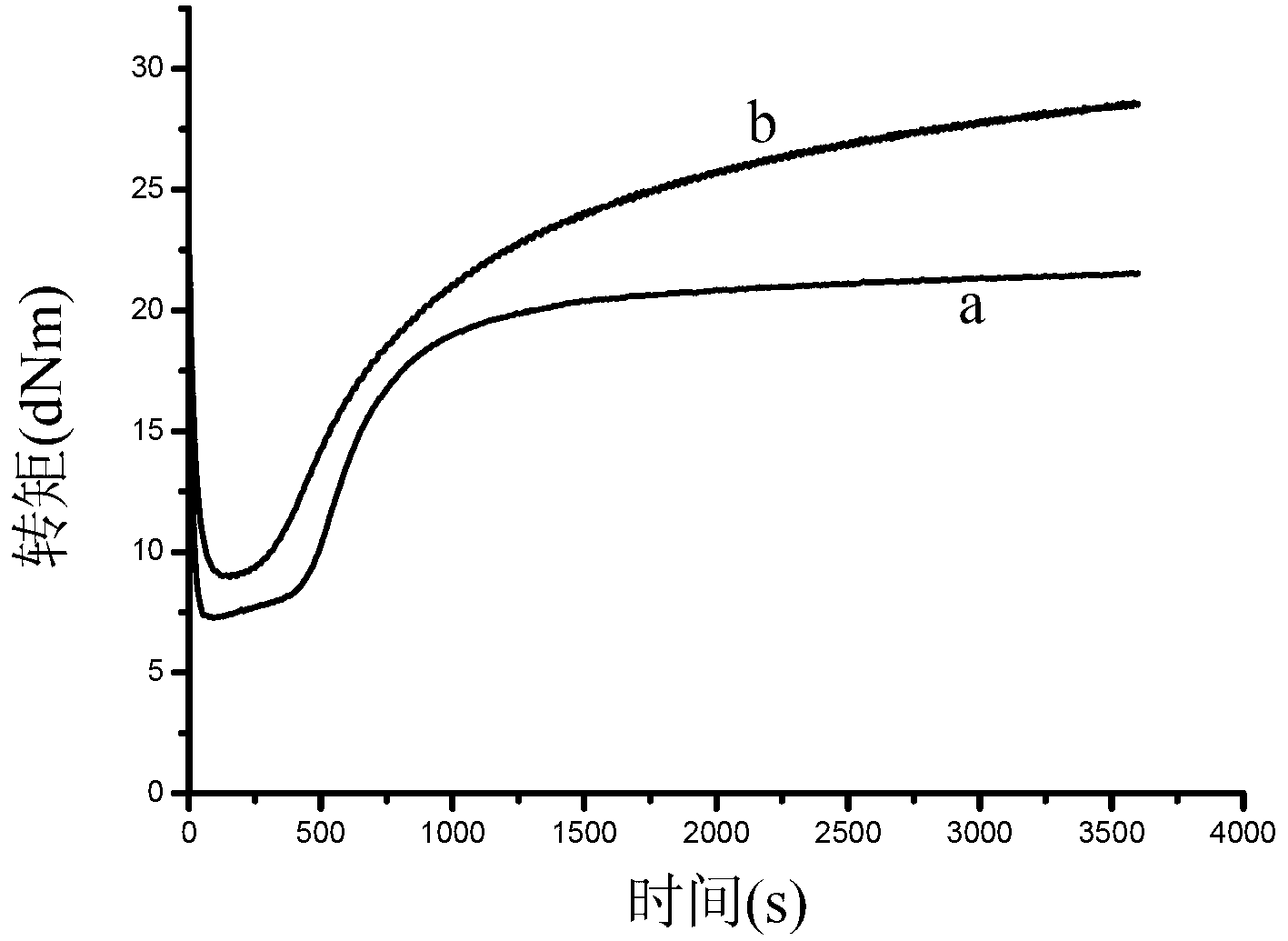

[0033] According to the formula in Table 1, the dosage of styrene-butadiene rubber 1502 is 100 parts, the dosage of carbon black N330 is 30 parts, the dosage of zinc oxide is 5 parts, and the dosage of quaternary ammonium salt is 0 parts. The time is 1h. Then test the vulcanization performance of the compound at 150°C. The vulcanization curve of the sample at 150°C is as follows figure 2 As shown in the middle curve (a), the 150°C vulcanization curve of the reference sample is as follows figure 2 Curve (b) in the middle; the vulcanization properties and physical and mechanical properties of the vulcanizate are shown in Table 3.

[0034] Table 3 Effect of zinc oxide on properties of styrene-butadiene rubber

[0035]

[0036]

[0037] From the results in Table 3, it can be seen that compared with the reference sample, T 10 Slightly extended, T 90 Shorten and increase the vulcanization speed; while its modulus, tensile strength, and tear strength are all improved. T...

Embodiment 3

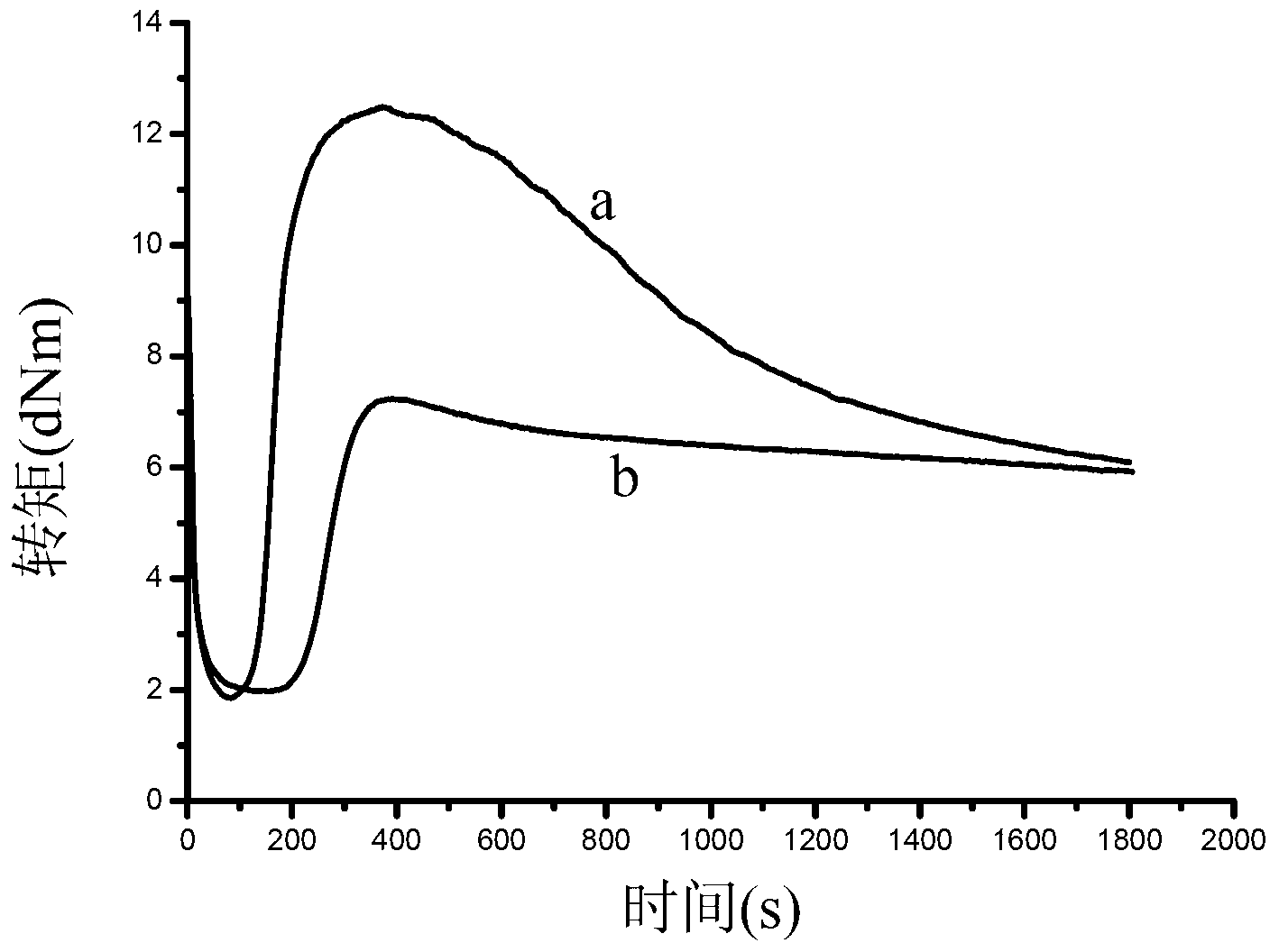

[0039] According to the formula in Table 1, the amount of natural rubber is 100 parts, the amount of carbon black is 30 parts, the amount of zinc oxide is 0 parts, and the amount of octadecyltrimethylammonium bromide is 3 parts. Mixing, the mixing temperature is 50 ° C, and the vulcanization temperature is 143°C, curing time is 1h. Then test the vulcanization performance of the compound at 143°C. The vulcanization curve of the sample at 143°C is as follows image 3 As shown in the middle curve (a), the 143°C vulcanization curve of the reference sample is as follows image 3 Curve (b) in the middle; the vulcanization properties and physical and mechanical properties of the vulcanizate are shown in Table 4.

[0040] Table 4 The influence of quaternary ammonium salts on the properties of natural rubber

[0041]

[0042] As can be seen from the results in Table 4: compared with the reference sample, the T containing 3 parts of quaternary ammonium salt rubber 10 shortened, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com