Kitchen sewage treatment device

A sewage treatment device and technology for sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Achieving the effect of easy maintenance, reduced cleaning burden, and reduced burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

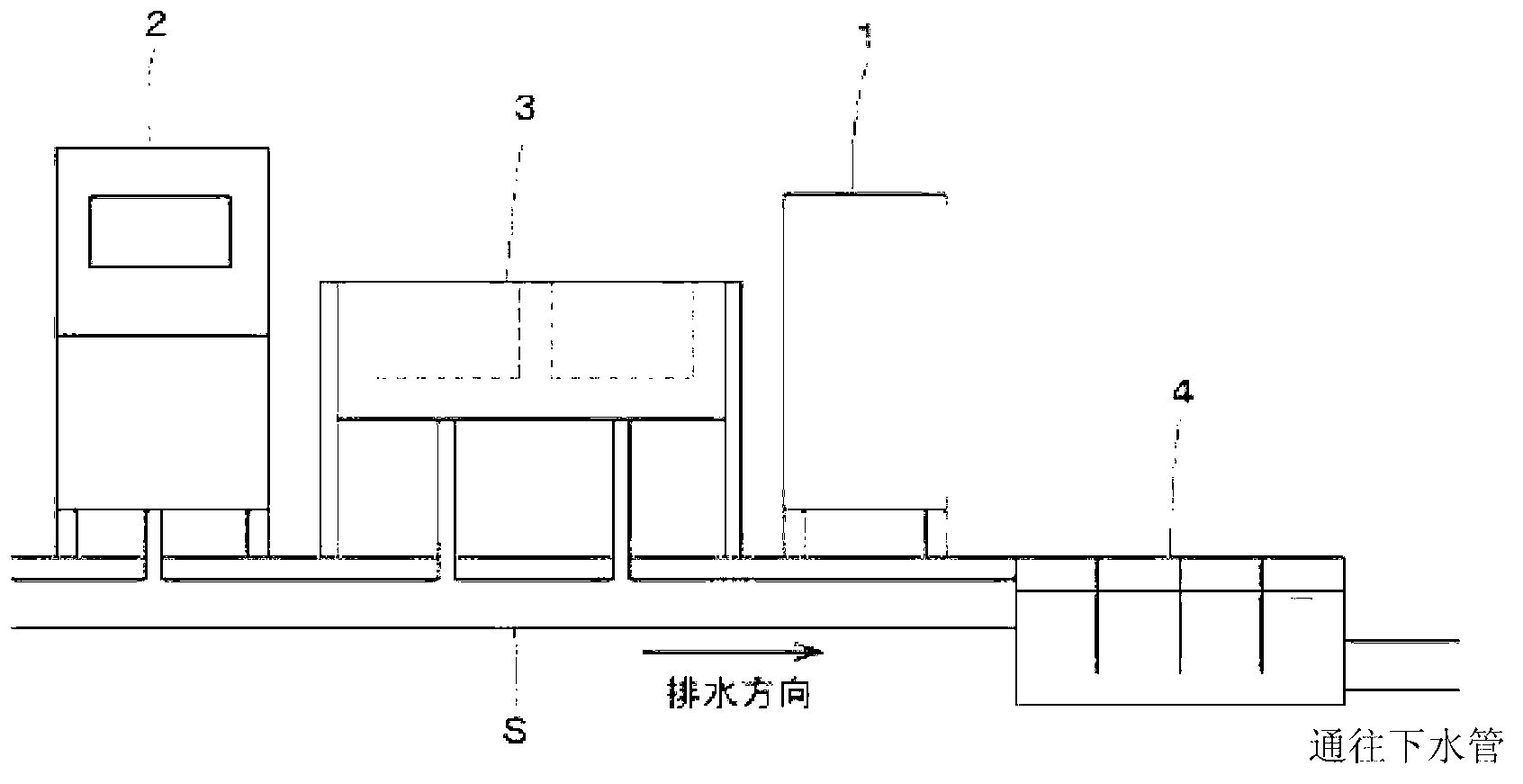

[0050] Embodiments of the present invention will be described below with reference to the drawings. first, figure 1 It shows the layout of a general business kitchen, and also exemplifies the installation state of this device 1. The dishwasher 2 is installed upstream of the sewage path S, the sink 3 has two sinks, and the grease trap 4 is installed on the sewage path. S's dirty. In this layout, the device 1 is arranged at the upstream part of the grease trap 4, which can reduce the grease separation burden of the grease trap 4.

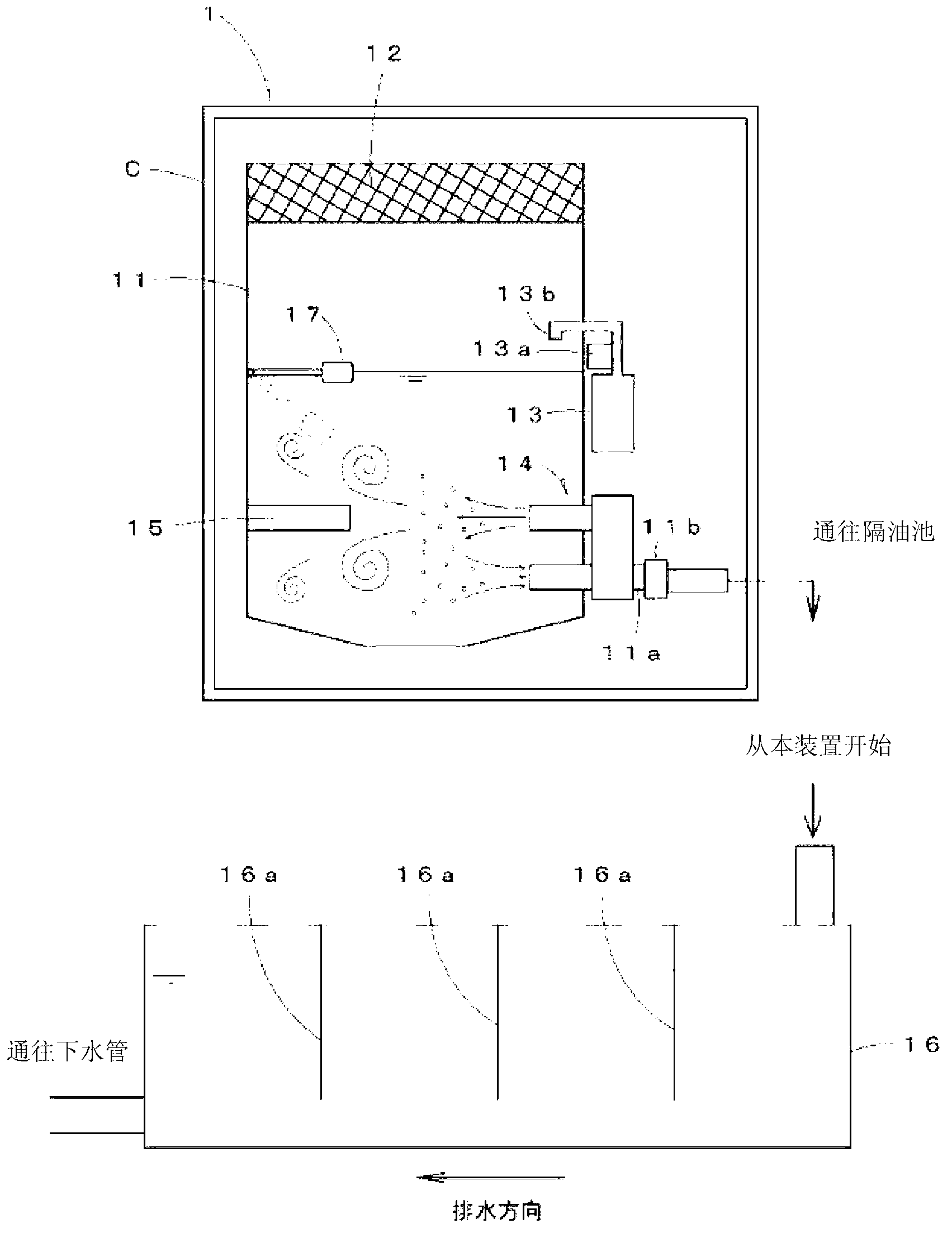

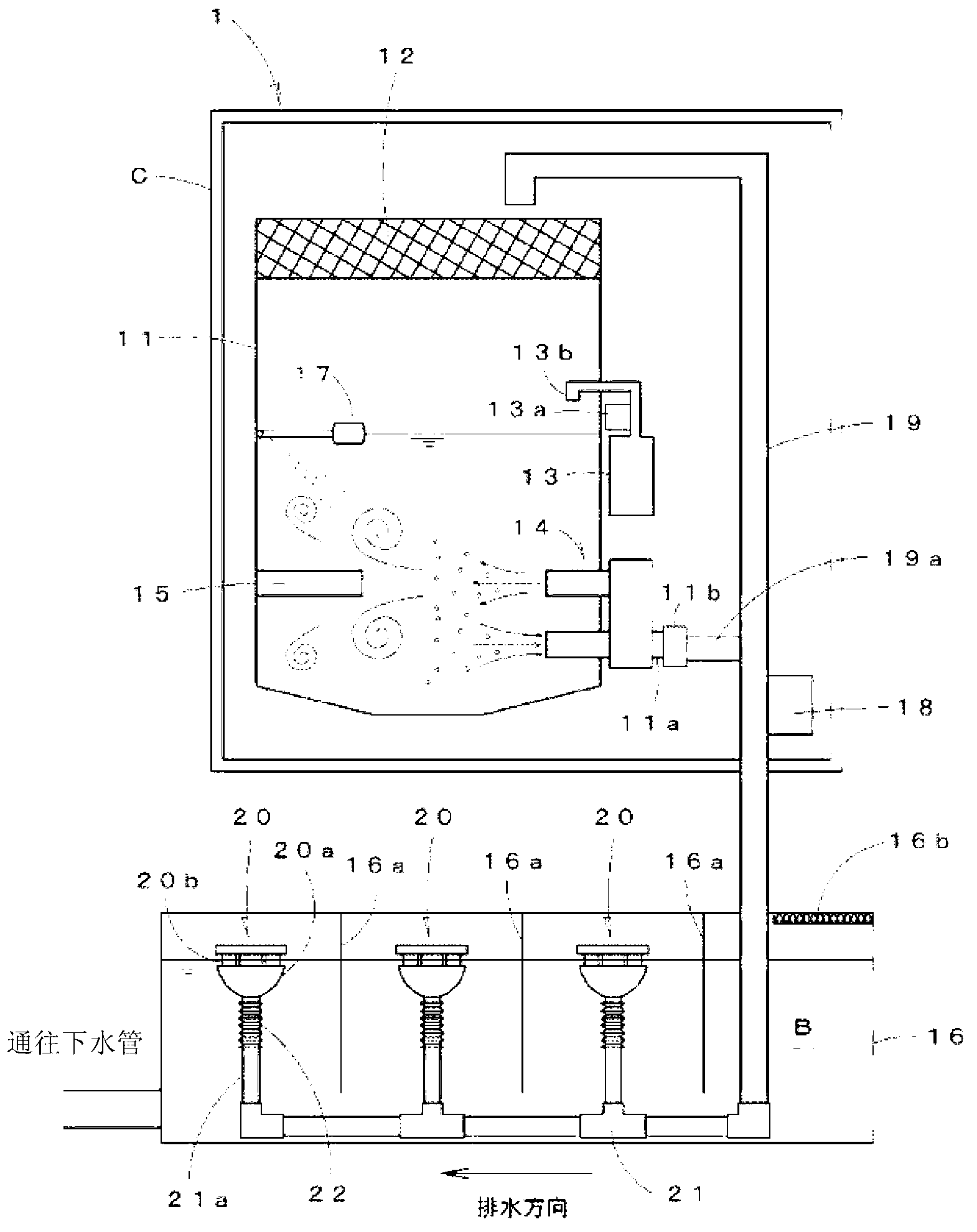

[0051] figure 2 For the first embodiment, a filter frame 12 is arranged on the top of the grease decomposition tank 11, and the medicament feeder 13 injects the grease decomposition agent from the liquid inlet 13b into the grease decomposition tank 11 by squeezing the liquid inlet pump 13a, and the aerator 14 performs its Stirring, 15 for the heater. The above-mentioned components are all arranged in the box C. In addition, the grease trap 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com