Silk-screen printing fixture and using method thereof

A fixture and screen printing technology, used in screen printing machines, printing, printing machines, etc., can solve problems such as reducing positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

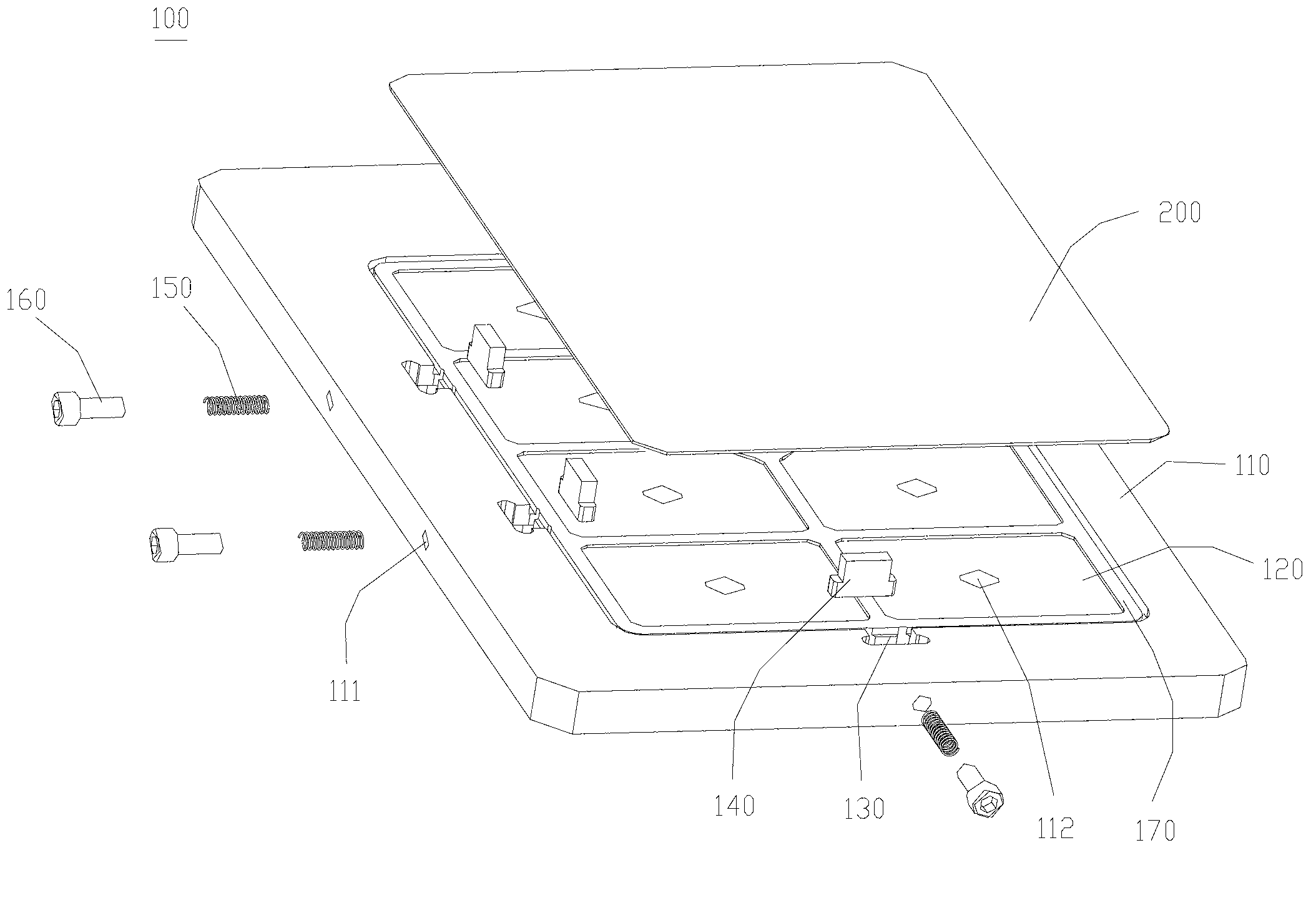

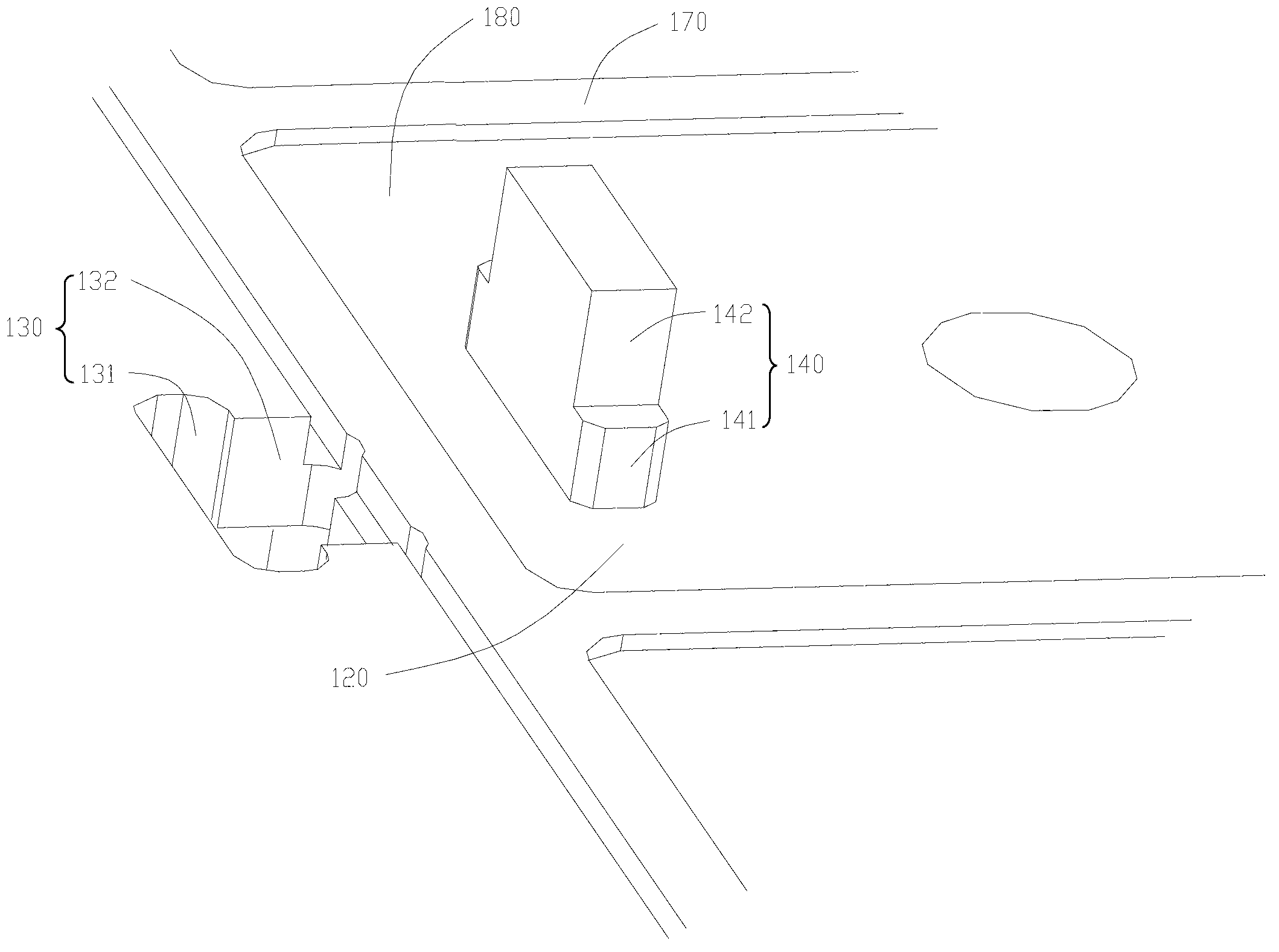

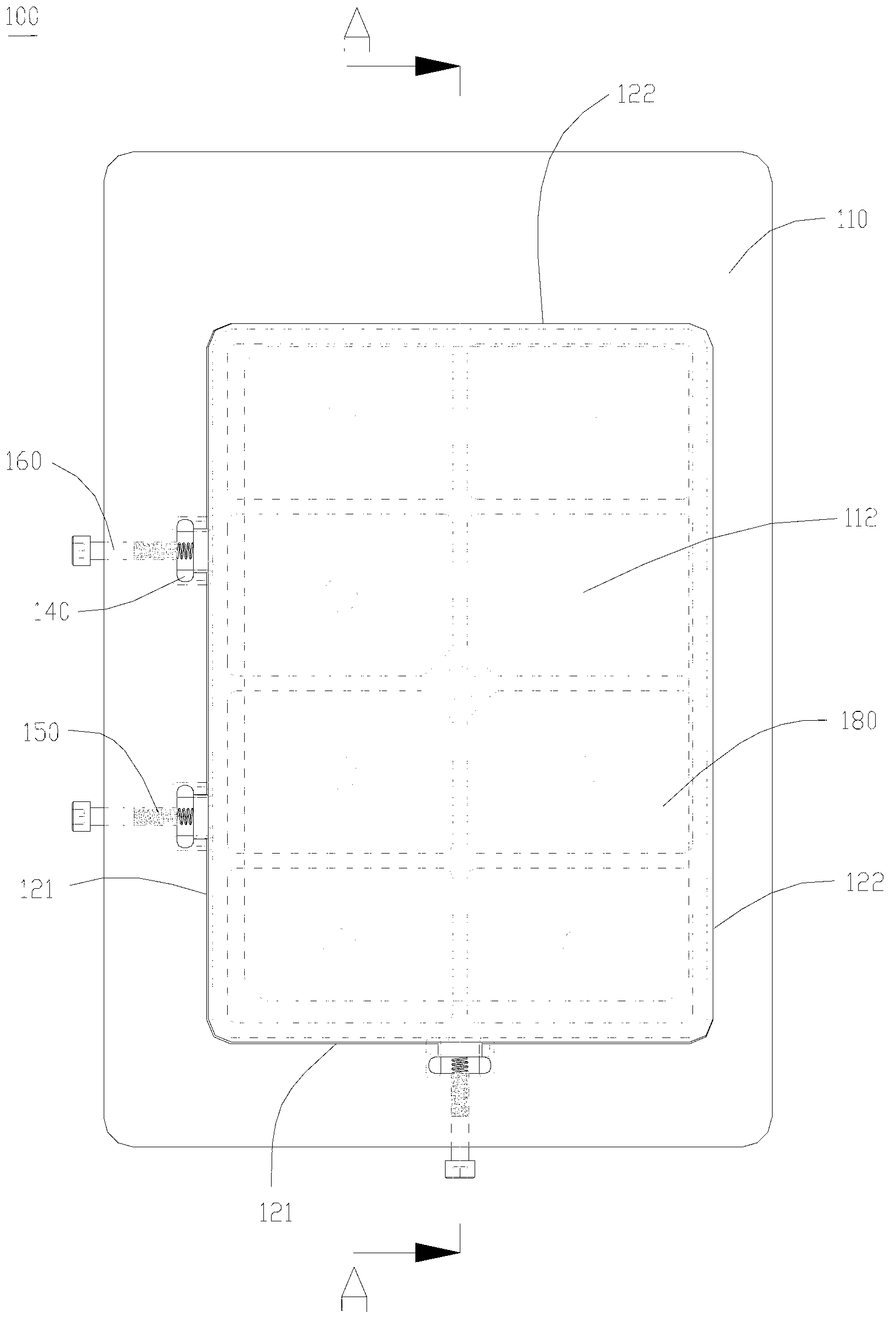

[0024] see figure 1 and image 3 , a screen printing fixture 100, including a base plate 110 and a pressing mechanism, the base plate 110 is provided with a cavity 120 that can fit with a clearance of the workpiece 200 to be printed, and the base plate 110 includes an opposite first inner wall 121 and a second inner wall 122 , the first inner wall 121 and the second inner wall 122 are both inner walls of the cavity 120 . The first inner wall 121 is provided with a chute groove 130, the pressing mechanism is slid in the chute groove 130 and can abut against the to-be-printed piece 200, and the pressing mechanism compresses the to-be-printed piece 200. The printing part 200 , so that the side of the printing part 200 is closely attached to the second inner wall 122 .

[0025] Specifically, the shape, structure and size of the bottom plate 110 can be processed and formed according to the needs of actual production. Generally, the bottom plate 110 is a rectangular parallelepiped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com