The nailing gun with the striker separated from the nail in advance

A technology for nailing guns and nails, which is applied in the field of nailing guns, and can solve problems such as the nailing gun is prone to failure, the striker cannot be released, and the nails are not squeezed normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

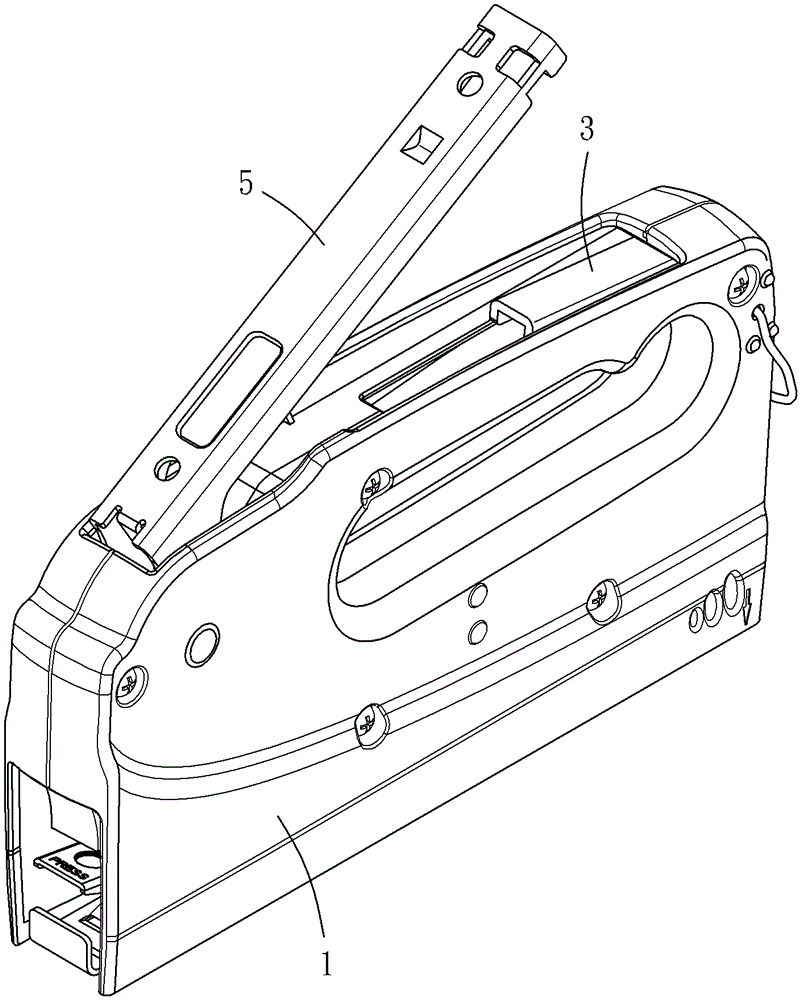

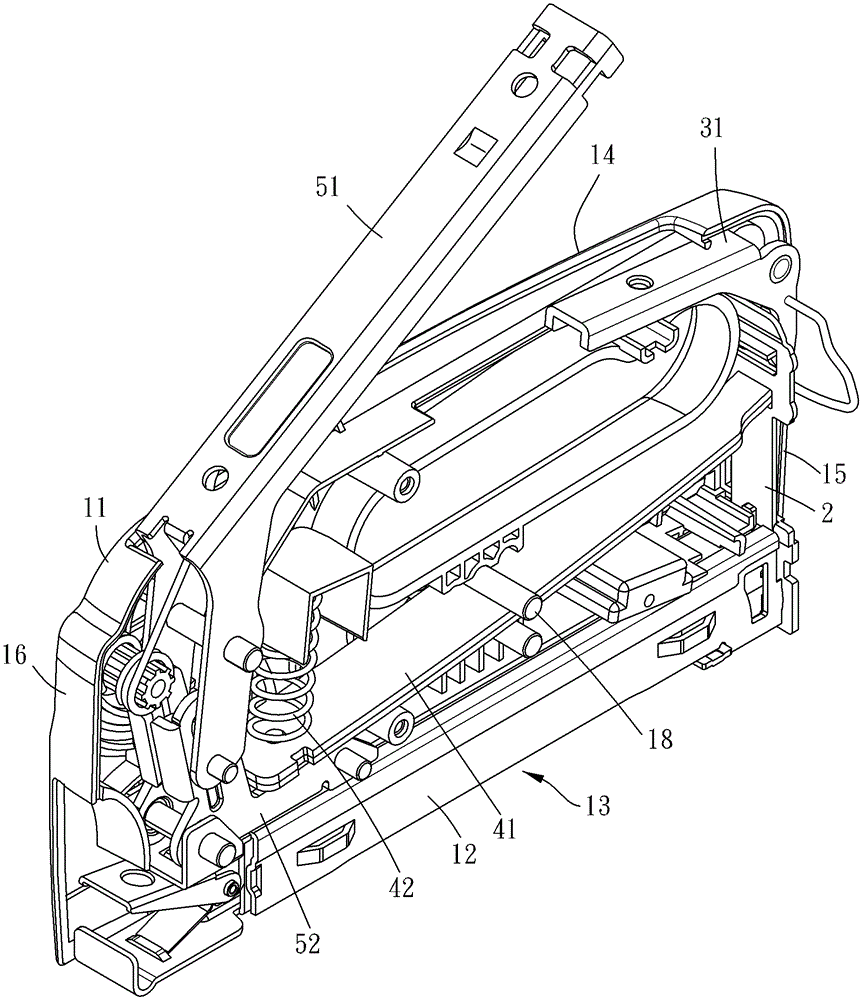

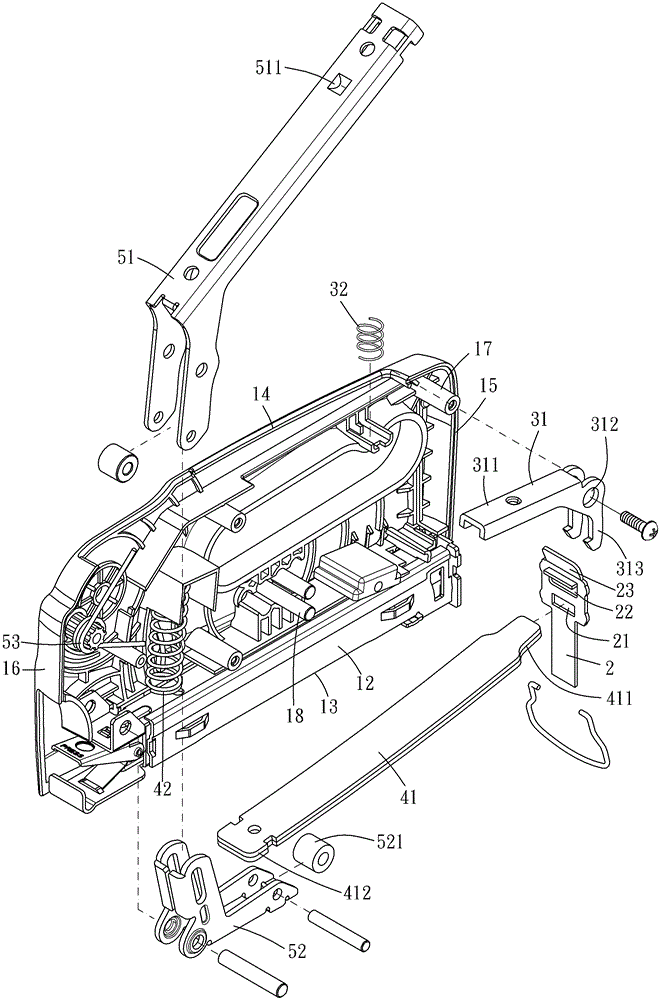

[0024] Please refer to figure 1 , The present invention provides a nailing gun, which is equipped with a nail, and accumulates the force required for driving the nail by manual pressing, which can be pressed by the user to drive out the nail. Please refer to Figure 1 to Figure 3 , The nailing gun provided by the present invention includes a housing 1 , a striking plate 2 , a limiting mechanism 3 , a power storage mechanism and an operating mechanism 5 .

[0025] The casing 1 mainly includes two half-shells 11 and a nail box 12, the half-shells 11 are fixed to each other by screws for the nail box 12 to be installed therein, and for further installation of other components, the shell has the ability to abut against objects and provide The bottom side 13 driven by the nail needle, the top side 14 corresponding to the bottom side, and the corresponding front end 15 and rear end 16, the nail box 12 is filled and entered by the rear end 16, so that the nail needle can be adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com