Automatic oil coating feeding device before sheet stamping forming

A sheet metal stamping and feeding device technology is applied in the field of sheet metal forming feeding equipment, which can solve the problems of high labor intensity and low production efficiency, and achieve the effects of reducing labor intensity, improving production efficiency, and reducing hidden dangers in production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

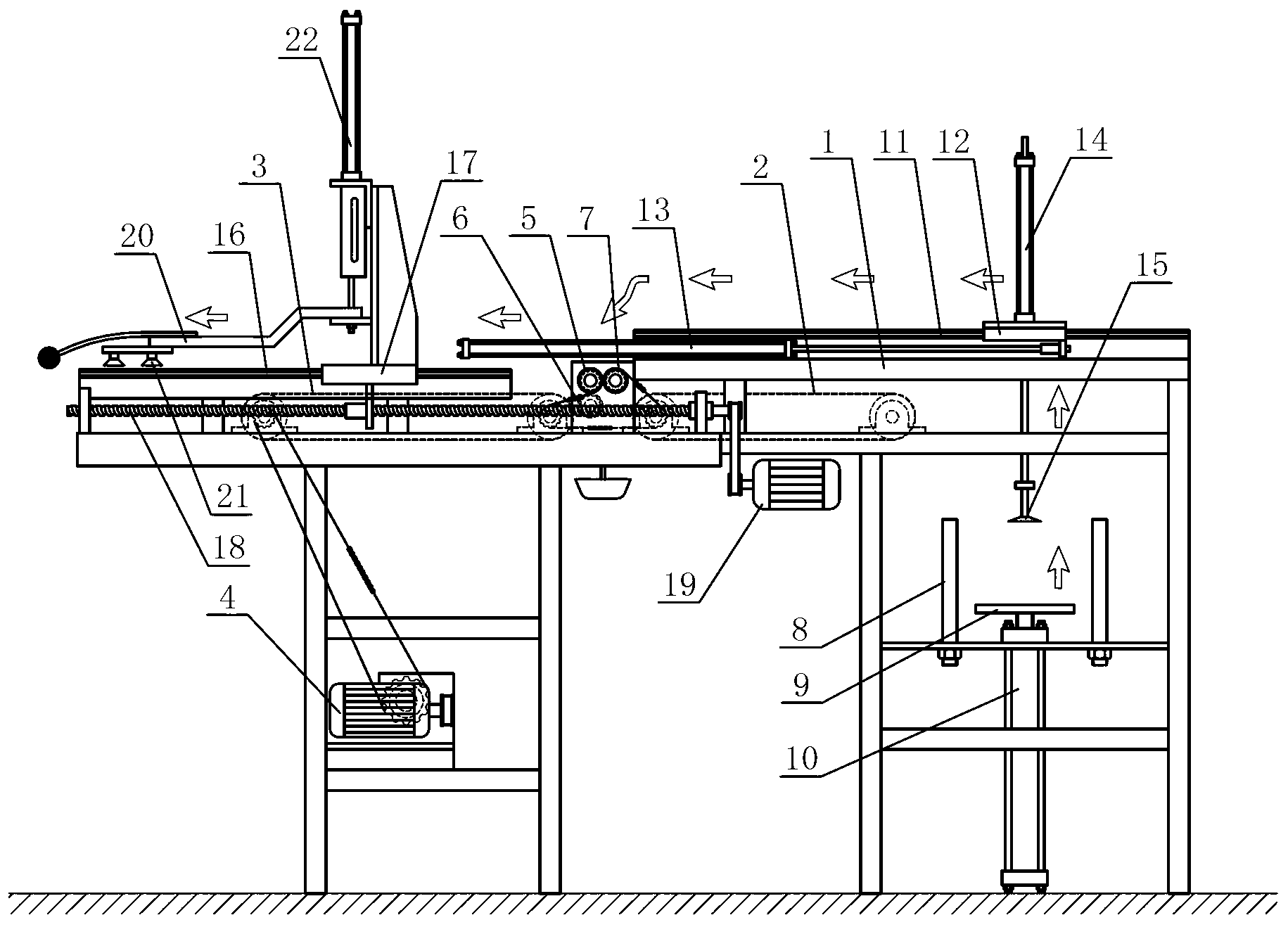

[0007] Such as figure 1 As shown, an automatic oiling and feeding device before sheet metal stamping and forming includes a frame 1, and two sets of conveyor belts 2 and 3 arranged forward and backward along the transmission direction are installed on the frame 1, and the two sets of conveyor belts 2 and 3 are driven by motors. 4 Drive synchronously to rotate through the transmission chain, between the two sets of conveyor belts 2 and 3, there is an oiling roller set, the oiling roller set includes up and down installation, which can roll the sheet from the front set of conveyor belts 2 to the rear set of conveyor belts 3. The oil roller 5 and the backup roller 6, and the oil roller 7 that is positioned at the side of the oil roller 5 and rolls opposite the oil roller 5, the backup roller 6 and the oil roller 7 are connected to be synchronized with the conveyor belts 2 and 3 by a transmission chain. To rotate, while the oiling roller 5 is connected to synchronously reverse rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com