Automatic steel rolling and stamping simulation device

A simulation device and automatic technology, applied in teaching models, educational tools, instruments, etc., can solve problems that cannot truly reflect industrial field applications, do not make full use of hydraulic and pneumatic transmission, and cannot meet the needs of teaching training and practical training. To achieve the effect of easy maintenance and assessment, rich training items and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

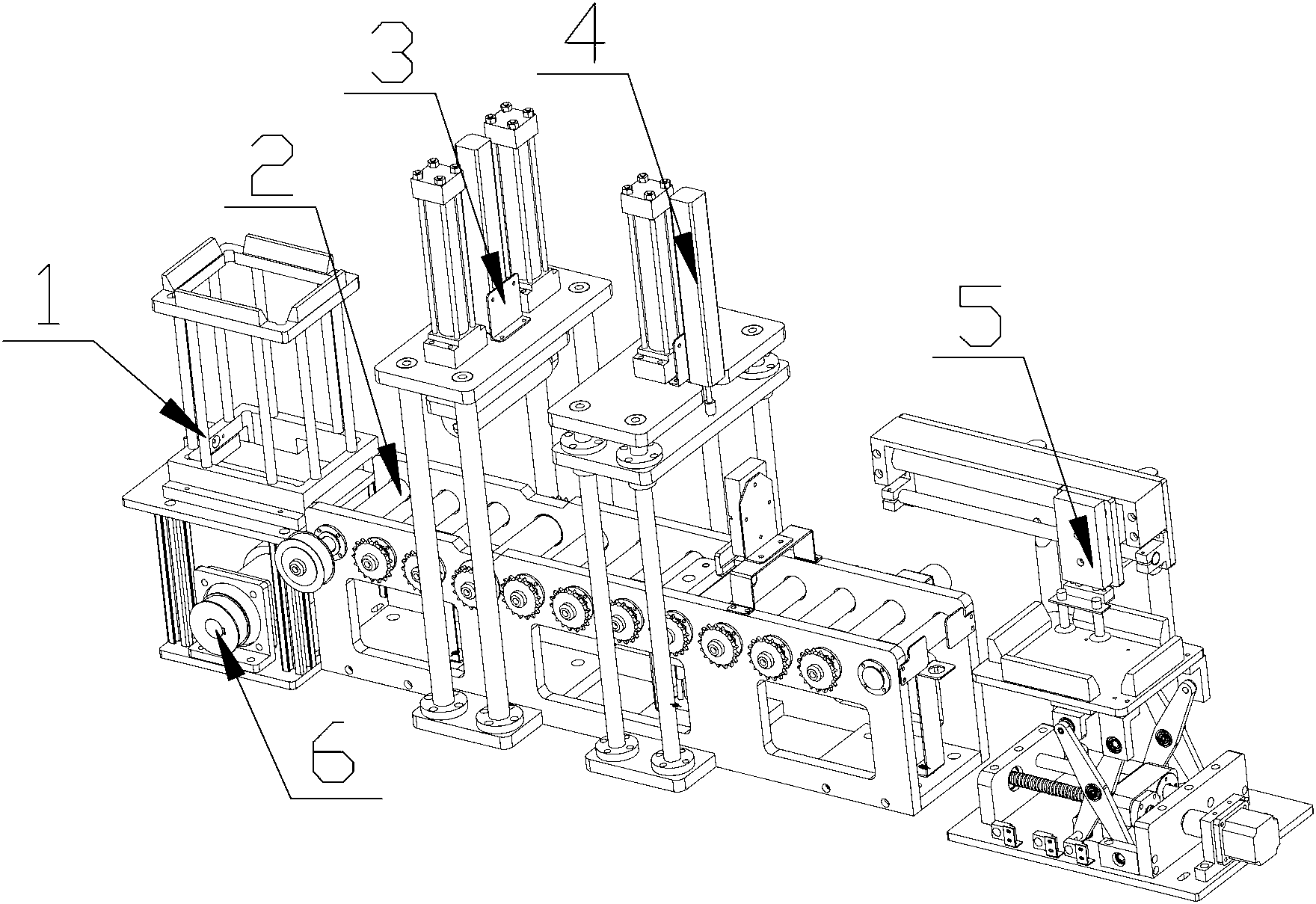

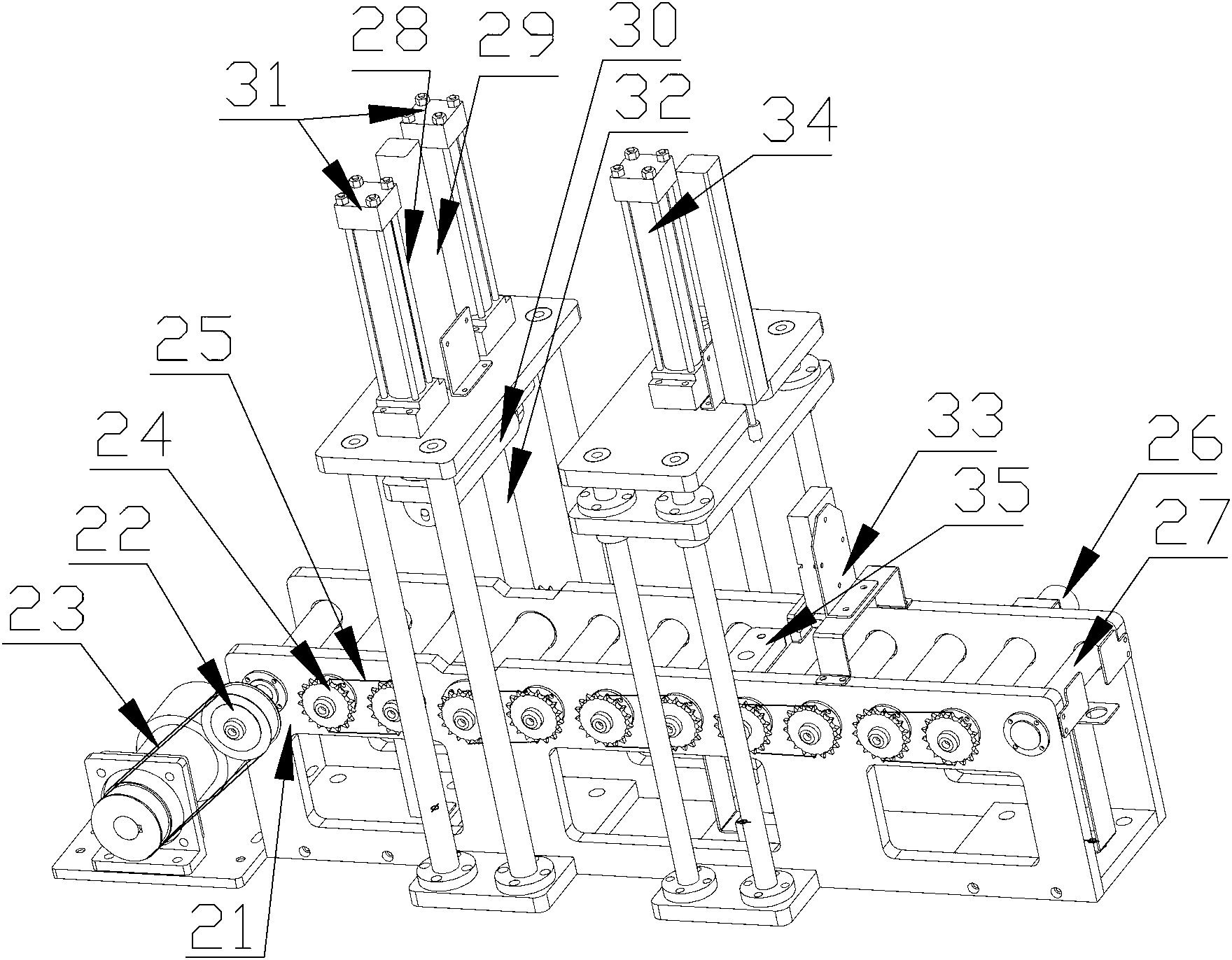

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an automatic steel rolling and stamping simulation device includes a loading unit 1, a conveying unit 2, a rolling unit 3, a stamping unit 4 and a blanking unit 5, each of which can operate independently or form a system combination Run to complete the simulated working process of automatic steel rolling.

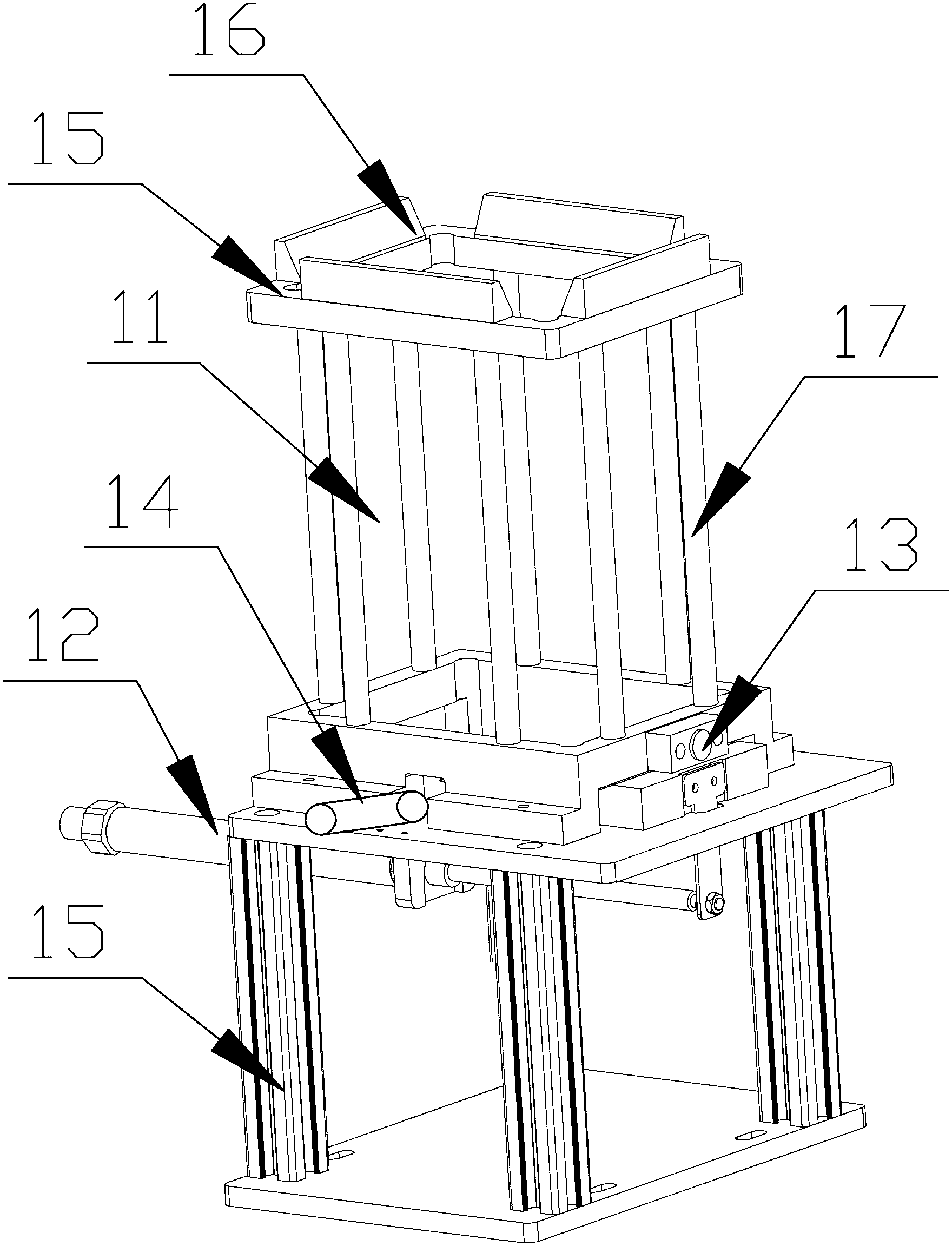

[0020] The feeding unit is at least composed of a square well frame 11, a needle cylinder 13, a material pushing cylinder 12, a material rack 15, and a sensor 14. The mouth 16 of the square well frame 11 is square, and the bottom of the mouth 16 is A set of supporting columns 17 is provided, and this structure has the advantages of orderly, reliable and stable feeding. Different cylinders are used for positioning and pushing out materials, and the said pushing out material cylinder 12 is installed opposite to the direction of material pushing out, which can save space and better protect the pushing out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com