Plug-in flue gas flow measurement method and measurement device based on detection of oxygen content

A technology of flue gas flow and oxygen content, which is used in the measurement of flow/mass flow, measuring device, liquid/fluid solid measurement, etc. It can solve the problems of drastic changes in the stress and elastic coefficient of the detection rod, inaccurate measurement, etc., and is easy to install. Layout, high measurement accuracy, easy to retrofit and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

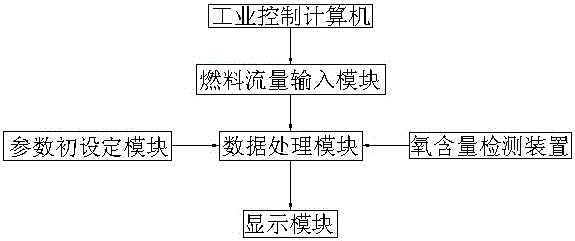

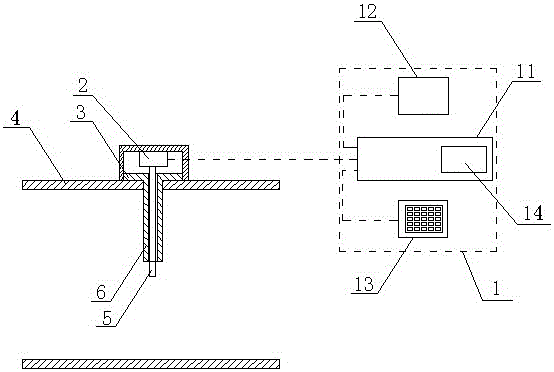

[0029] A plug-in flue gas flow measurement method based on detecting oxygen content, which measures the actual flue gas flow by detecting the oxygen content in the flue gas and calculating and processing the data, including the following steps:

[0030] Step 1, input the content of each component of the fuel and the fuel flow rate from the input end of the data processing device 1, and calculate the theoretical air ratio of the fuel in the data processing device 1 according to the content of each component of the fuel and the chemical reaction equation of the combustible components therein , at the same time, the theoretical smoke ratio of the fuel is calculated according to the residual air component of complete combustion, and then the theoretical air flow is calculated by formula 1 according to the fuel flow rate, and the theoretical smoke gas flow rate is calculated by formula 2;

[0031] Theoretical air flow = fuel flow × theoretical air ratio Formula 1

[0032] Theoretic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com