Method for calculating part conicity based on minimum zone

A technology of minimum area and calculation method, applied in the direction of measuring devices, instruments, etc., can solve problems such as poor calculation stability, difficulty in applying the minimum area method, and difficulty in achieving calculation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

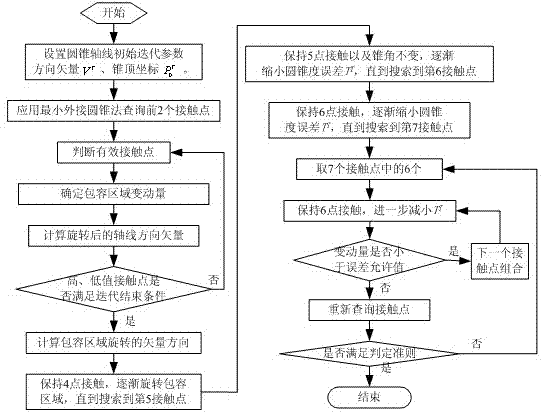

[0081] A method for calculating the conicity of parts based on the smallest area, when the cone angle is a variable, mainly includes the following steps:

[0082] Step 1: Place the measured cone on the measurement platform, measure and obtain the measuring points on the surface of the cone in the rectangular coordinate system of the measurement space ,in =1, 2,..., n , n Represents the number of measuring points and is a positive integer greater than 7; all measuring points Form a point set ; Randomly give the initial parameters of the cone, including the apex coordinates of the outer enclosing cone , the direction vector of the cone axis and half cone angle ;in The direction of the vector is from the small end of the cone to the large end; set the allowable value of the error .

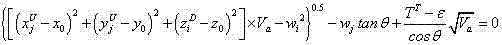

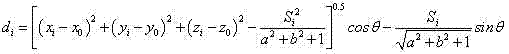

[0083] Step 2: Apply the following formula to calculate each measuring point in turn distance to cone ,

[0084]

[0085] in , all measuring points corresponding to Form...

Embodiment 2

[0122] A method for calculating the conicity of parts based on the smallest area. When the cone angle is constant, it is basically similar to the calculation process of Embodiment 1. The difference is that the cone angle is kept constant during the change of the containment area. It mainly includes the following steps:

[0123] Step 1: Place the measured cone on the measurement platform, measure and obtain the measuring points on the surface of the cone in the rectangular coordinate system of the measurement space ,in =1, 2,..., n , n Represents the number of measuring points and is a positive integer greater than 7; all measuring points Form a point set ; Randomly give the initial parameters of the cone, including the apex coordinates of the outer enclosing cone , the direction vector of the cone axis ;According to the drawing information, get the half cone angle ;in The direction of the vector is from the small end of the cone to the large end; set the allowab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com