Double-stage variable-speed oppositely-rotating axial flow pump flow passage component for water spraying propelling

A water jet propulsion and flow-passing component technology, which is applied in the field of pump flow-flow components, can solve the problems of narrow high-efficiency range, poor anti-cavitation performance, impeller corrosion and damage of axial flow pumps, etc. Good chemical performance and wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

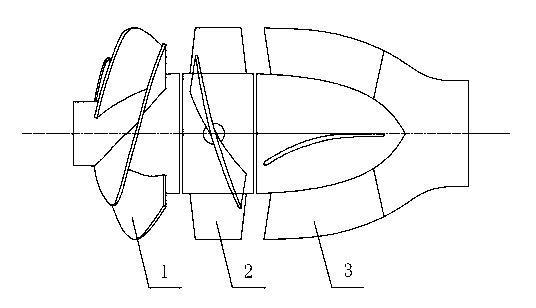

[0017] From the water inlet to the water outlet, the primary impeller 1, secondary impeller 2 and guide vane 3 are installed in sequence. Upper; the speed n of the first stage impeller 1 1 with secondary impeller 2 speed n 2 than n 1 :n 2 =1, the rotation direction of the primary impeller 1 is opposite to that of the secondary impeller 2; the primary impeller 1 is in the form of an inducer, the hub is conical, the smaller end of the hub is the water inlet, and the diameter ratio of the inlet hub is d h : D =0.25, outlet hub diameter ratio d h : D =0.4; the number of blades Z of first stage impeller 1 1 With secondary impeller 2 blade number Z 2 are mutually prime numbers, Z 1 = 2, Z 2 = 3; first-stage impeller 1 cascade denseness s = 1.5; axial clearance S between first-stage impeller 1 and secondary impeller 2, and between secondary impeller 2 and guide vane 3 is 10% of impeller outer diameter D. The device is driven separately by two impellers and two motors to reali...

Embodiment 2

[0019] From the water inlet to the water outlet, the primary impeller 1, secondary impeller 2 and guide vane 3 are installed in sequence, the primary impeller 1, secondary impeller

[0020] The centerlines of wheel 2 and guide vane 3 are on the same straight line and are respectively installed on different shafts; the speed n of the first stage impeller 1 1 with secondary impeller 2 speed n 2 than n 1 :n 2 =1.5, the first-stage impeller 1 and the secondary impeller 2 rotate in the opposite direction; the first-stage impeller 1 is in the form of an inducer, the hub is conical, the smaller end of the hub is the water inlet, and the diameter ratio of the inlet hub is d h : D =0.3, outlet hub diameter ratio d h : D =0.5; the number of blades Z of first stage impeller 1 1 With secondary impeller 2 blade number Z 2 are mutually prime numbers, Z 1 = 2, Z 2 = 5; first-stage impeller 1 cascade density s = 2.25; the axial gap S between the first-stage impeller 1 and the secondary...

Embodiment 3

[0022] From the water inlet to the water outlet, the primary impeller 1, secondary impeller 2 and guide vane 3 are installed in sequence, the primary impeller 1, secondary impeller

[0023] The centerlines of wheel 2 and guide vane 3 are on the same straight line and are respectively installed on different shafts; the speed n of the first stage impeller 1 1 with secondary impeller 2 speed n 2 than n 1 :n 2 =2, the rotation direction of the primary impeller 1 is opposite to that of the secondary impeller 2; the primary impeller 1 is in the form of an inducer, the hub is conical, the smaller end of the hub is the water inlet, and the diameter ratio of the inlet hub is d h : D =0.35, outlet hub diameter ratio d h : D =0.6; the number of blades Z of first stage impeller 1 1 With secondary impeller 2 blade number Z 2 are mutually prime numbers, Z 1 = 3, Z 2 = 5; first-stage impeller 1 cascade denseness s = 3; the axial gap S between the first-stage impeller 1 and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com