Water splashing resistant flush closet

A flush toilet and toilet body technology, applied in flush toilets, water supply devices, buildings, etc., can solve the problems of unclean flushing, excrement residue, toilet paper residue, etc., and achieve the effect of preventing water splashing, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

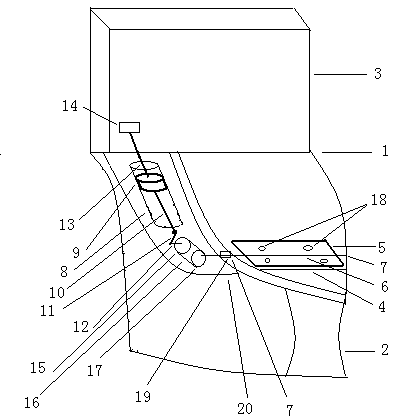

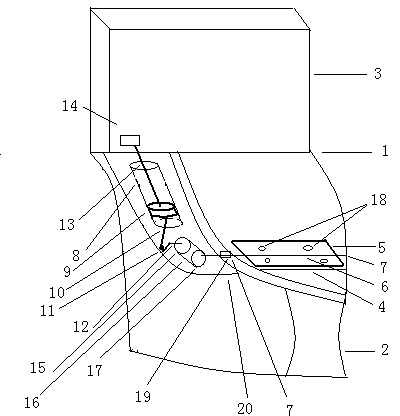

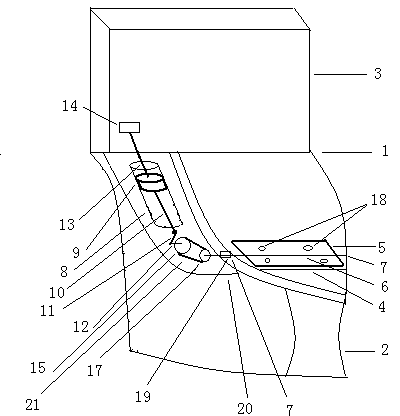

[0032] Such as figure 1 with figure 2 As shown, the splash-proof flush toilet 1 includes a toilet body 2 and a water tank 3, a flush button 14 is installed on the water tank 3, a water seal 4 is arranged in the urinal of the toilet body 2, and a baffle plate 5 is arranged, and the edge of the baffle plate 5 is in line with the The edge of the urinal maintains a suitable gap, the middle of the baffle 5 is installed with a pivot 6 rigidly connected to the baffle 5, and the two ends of the pivot 6 are installed at the corresponding two shaft holes 7 of the urinal, and the cylinder body 8, The crankshaft linkage mechanism composed of piston 9, connecting rod 10, crank 11 and shaft 12 is installed on the flush toilet 1, and one end of the pivot 6 passes through one of the shaft holes 7 of the urinal to rigidly connect with the driven wheel 17, and the crankshaft linkage mechanism The shaft 12 is rigidly connected to the driving wheel 15, and the driving wheel 15, the driven wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com