Micromechanical sensor arrangement, corresponding manufacturing method and application

A technology of micromechanical sensor and inertial sensor, which is applied in the direction of microstructure device, manufacturing microstructure device, processing microstructure device, etc., can solve the problem that the modular replacement of ASIC circuit chip cannot be easily realized, and achieve the elimination of geometric structure restrictions, Simplified structure technology and connection technology, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

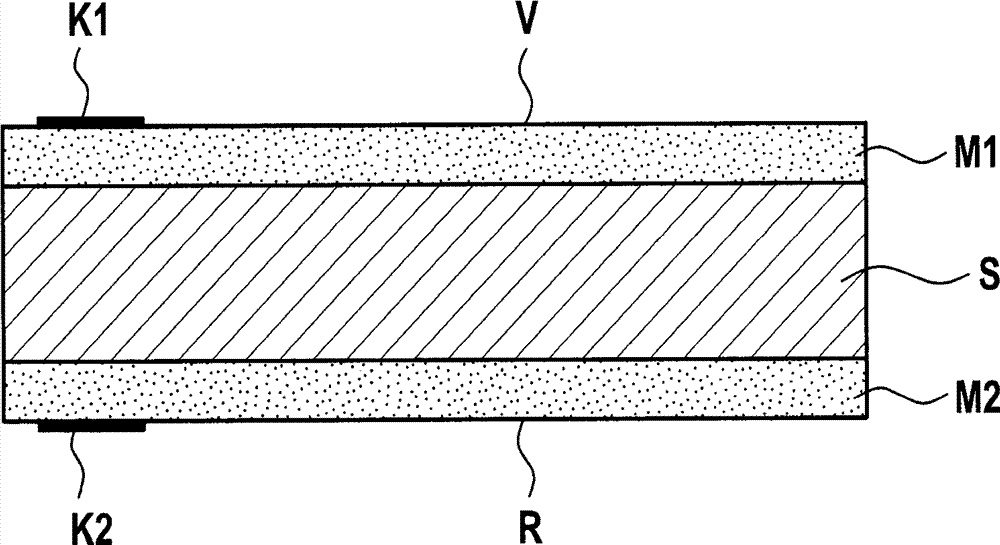

[0026] figure 1 A schematic cross-sectional view of a micromechanical sensor arrangement according to a first embodiment of the invention is shown.

[0027] exist figure 1 , the reference S designates a substrate, for example a silicon substrate, which has a front side V and a back side R. A first functional MEMS region M1 is integrated on the front side V and a second functional MEMS region M2 is integrated on the back side. A functional MEMS area is understood to mean that at least one sensor and / or actuator is built in this area. K1 designates the electrical contact area on the front side V, and K2 designates the electrical contact area on the rear side R. FIG.

[0028] Such an arrangement of the functional MEMS regions M1 , M2 on opposite sides V, R of the substrate S enables efficient integration, a small structural height and cost-effective process control.

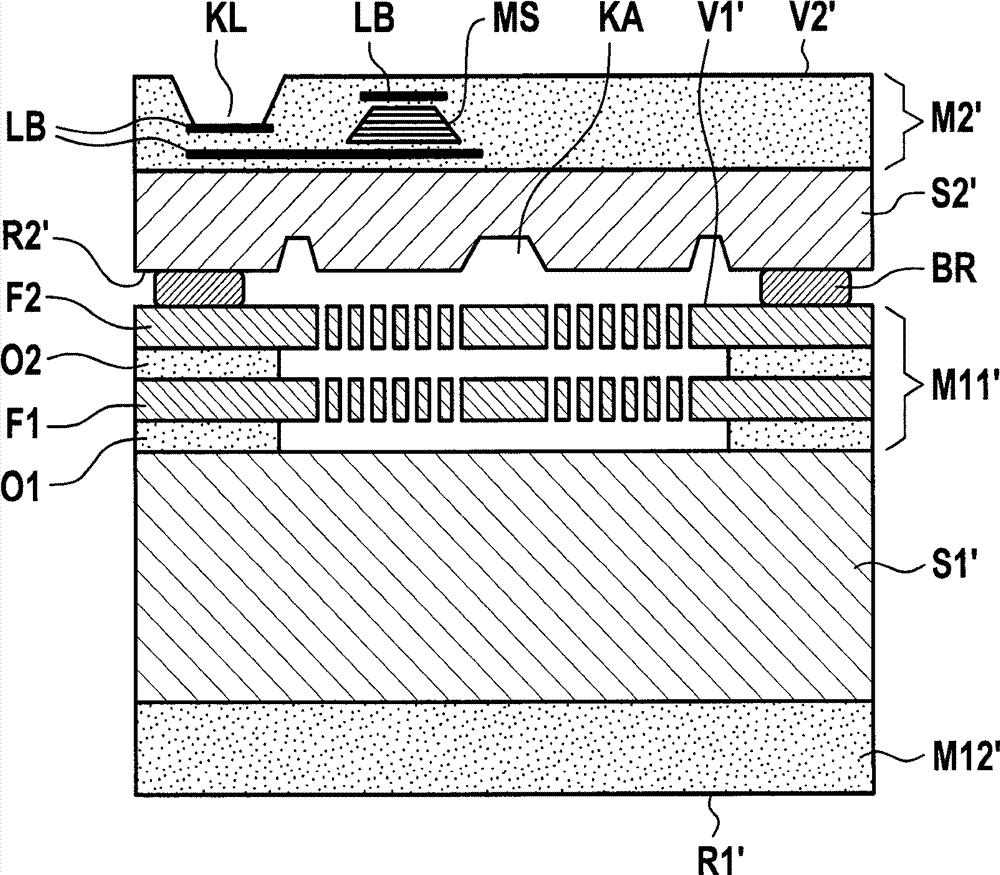

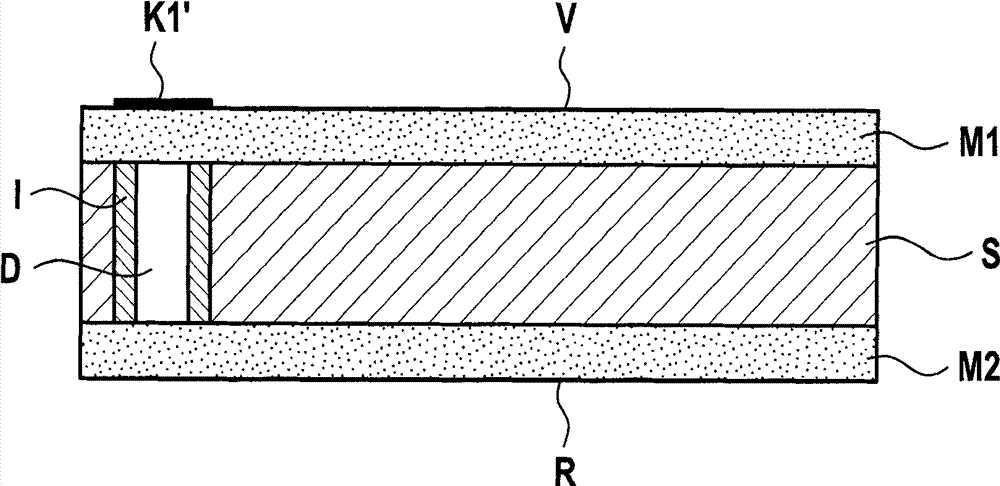

[0029] figure 2 A schematic cross-sectional view of a micromechanical sensor arrangement according to a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com