Floor type powdery material storehouse

A floor-standing, powder-based technology, applied in the field of floor-to-ceiling storage, can solve problems such as difficult inspection, potential safety hazards, casualties, etc., and achieve the effects of short construction period, convenient maintenance, and few supporting facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

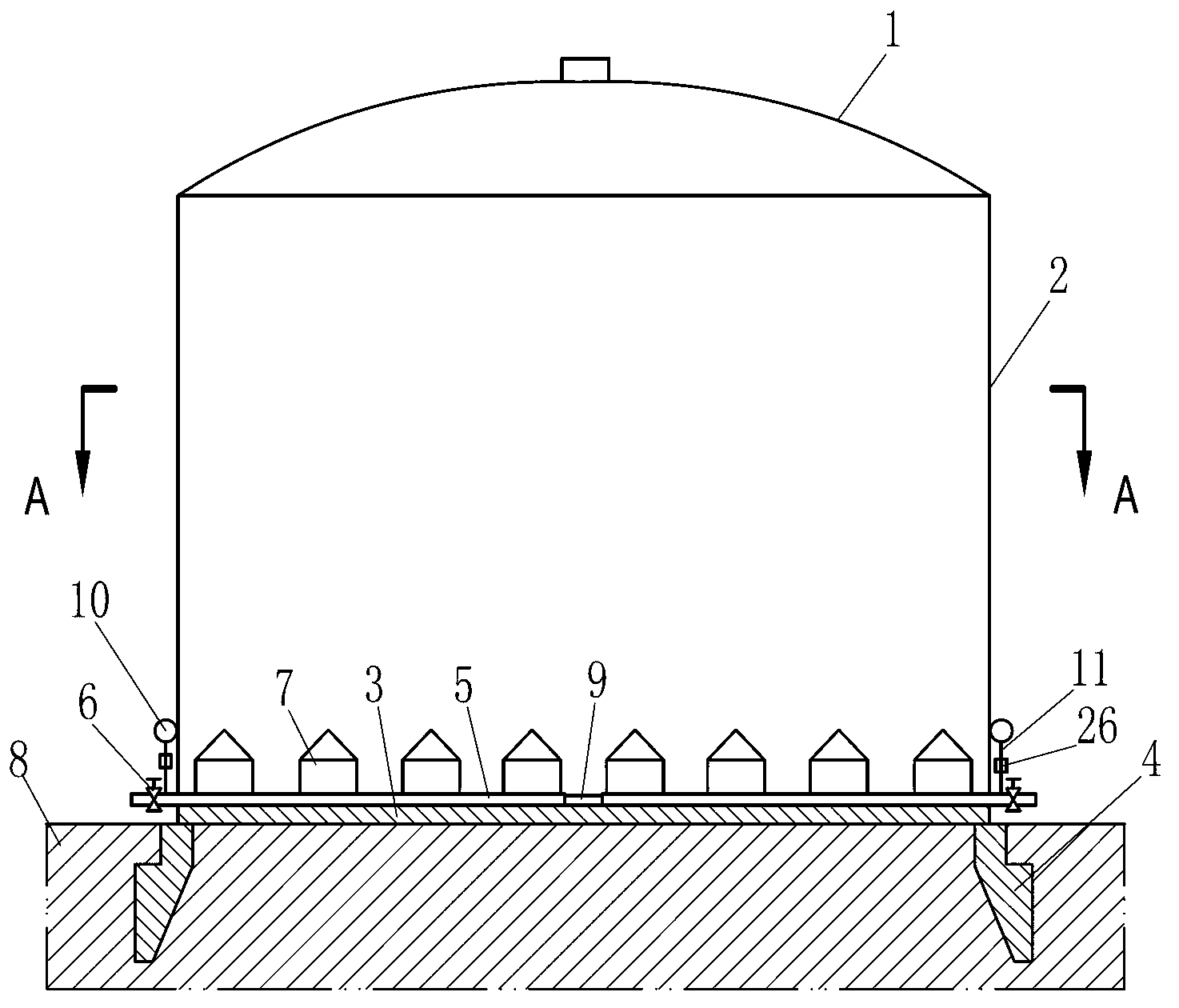

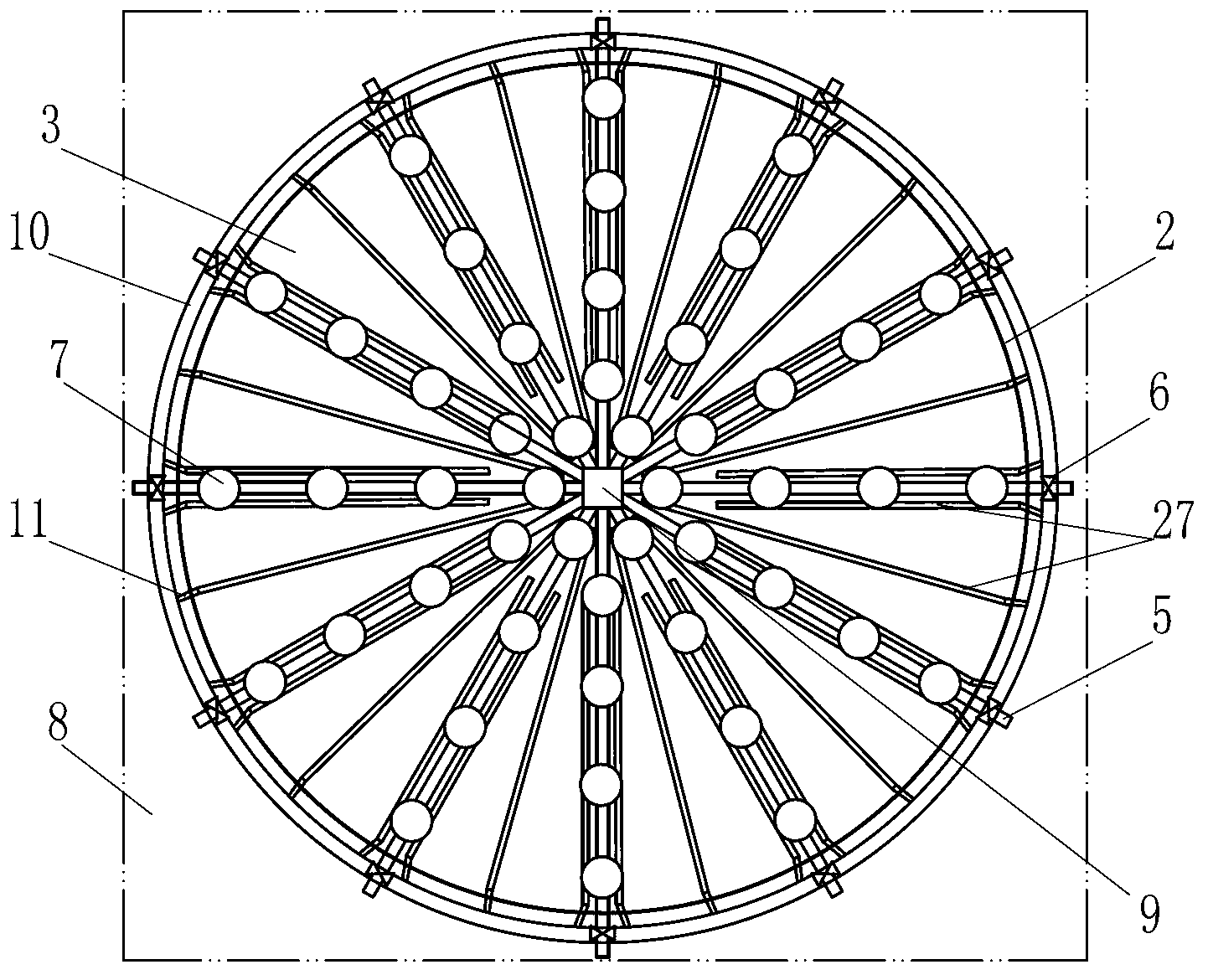

[0030] Such as figure 1 and figure 2 The floor-standing powder storage of the present invention includes a top 1, a wall 2, a bottom 3 and a foundation 4, and the top 1, wall 2, bottom 3 and foundation 4 are all made of reinforced concrete. When building the warehouse, the warehouse bottom 3 is directly set on the land 8, and the warehouse bottom 3 and the warehouse foundation 4 are integrated. The bottom of the storehouse 3 is provided with a material flow aid device 27, the material flow aid device is composed of a pneumatic fluidization rod, and the pneumatic fluidization rod is connected with an air supply pipeline, and the air supply pipeline includes a main air supply pipeline 10, and the main air supply pipeline 10 The branch gas supply pipeline 11 communicates with the pneumatic fluidization rod, and the branch gas supply pipeline 11 is provided with a valve 26 to control the passing gas volume and air pressure. In addition, the floor-type powder storage of the pres...

Embodiment 2

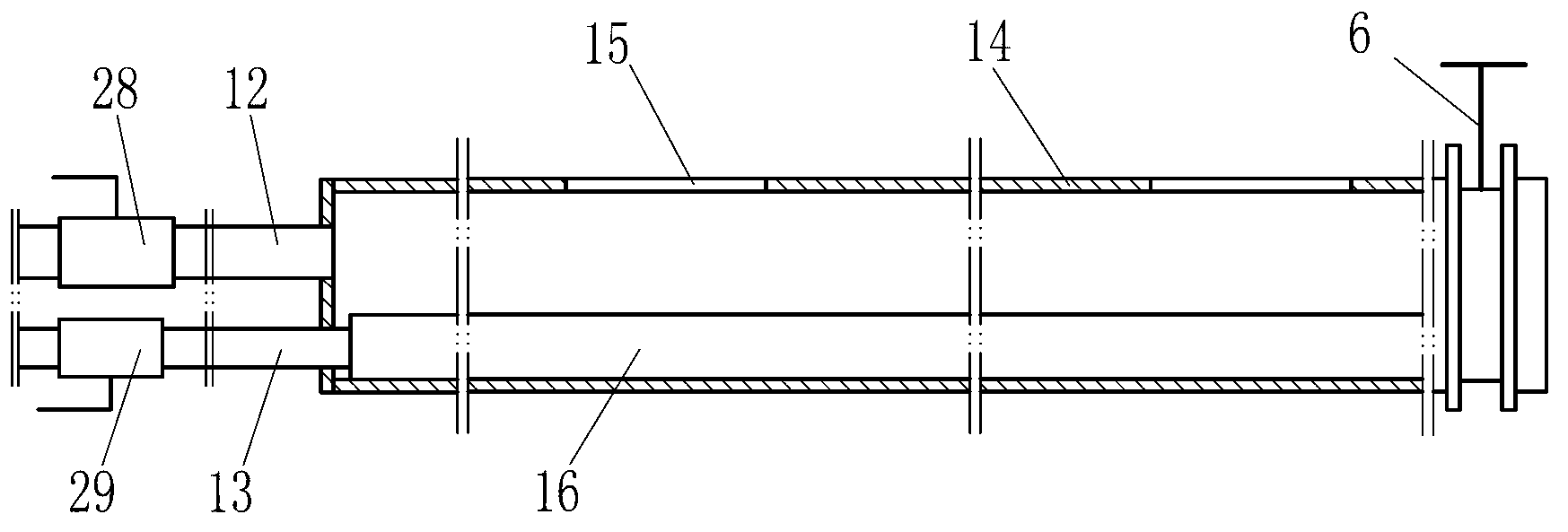

[0036] Such as Figure 6 , Figure 7 and Figure 8 The difference between the shown floor-standing powder storage of the present invention and Embodiment 1 is that the top 1, the wall 2, and the bottom 3 are made of steel, and the foundation 4 is made of reinforced concrete. Wall 2 is welded into one. The reclaiming device 5 is provided with seven, and the decompression chamber 7 is fixedly arranged on the material conveying pipe 14 in the reclaiming device 5. The decompression chamber is positioned at the top of the discharge port 15. The decompression chamber includes a decompression chamber body 18, and the decompression chamber includes a decompression chamber body 18. The side wall of the bin body 18 is provided with a feed opening 19 , and the pneumatic fluidization rod constituting the material flow aid device 27 partially extends below the decompression bin 7 . In addition, an enclosure 17 is also provided around the material feeding port 15 of the material conveyin...

Embodiment 3

[0040] Such as Figure 6 , Figure 7 , Figure 9 and Figure 10 The difference between the floor-standing powder storage of the present invention and the second embodiment is that, in order to meet the needs of long-distance horizontal feeding, in addition to increasing the number of discharge ports 15 provided on the material delivery pipe 14 in the reclaiming device 5, Corresponding to the blanking port 15 , the material conveying pipe 14 is also provided with a forward deflector 25 , and the forward deflector 25 is gradually inclined downward along the discharge direction of the material conveying pipe 14 . In addition, if Figure 9 As shown, the inner diameter of the chamber surrounded by the air-permeable cloth 23 in the pneumatic fluidization rod 16 is larger than the outer diameter of the steel pipe 21 .

[0041] Compared with Embodiment 2, in the floor-standing powder storage warehouse described in this example, due to the addition of a forward deflector 25 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com