Vacuum package machine

A technology of vacuum packaging machine and frame, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., and can solve the problems of follow-up procedure confusion and lower reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

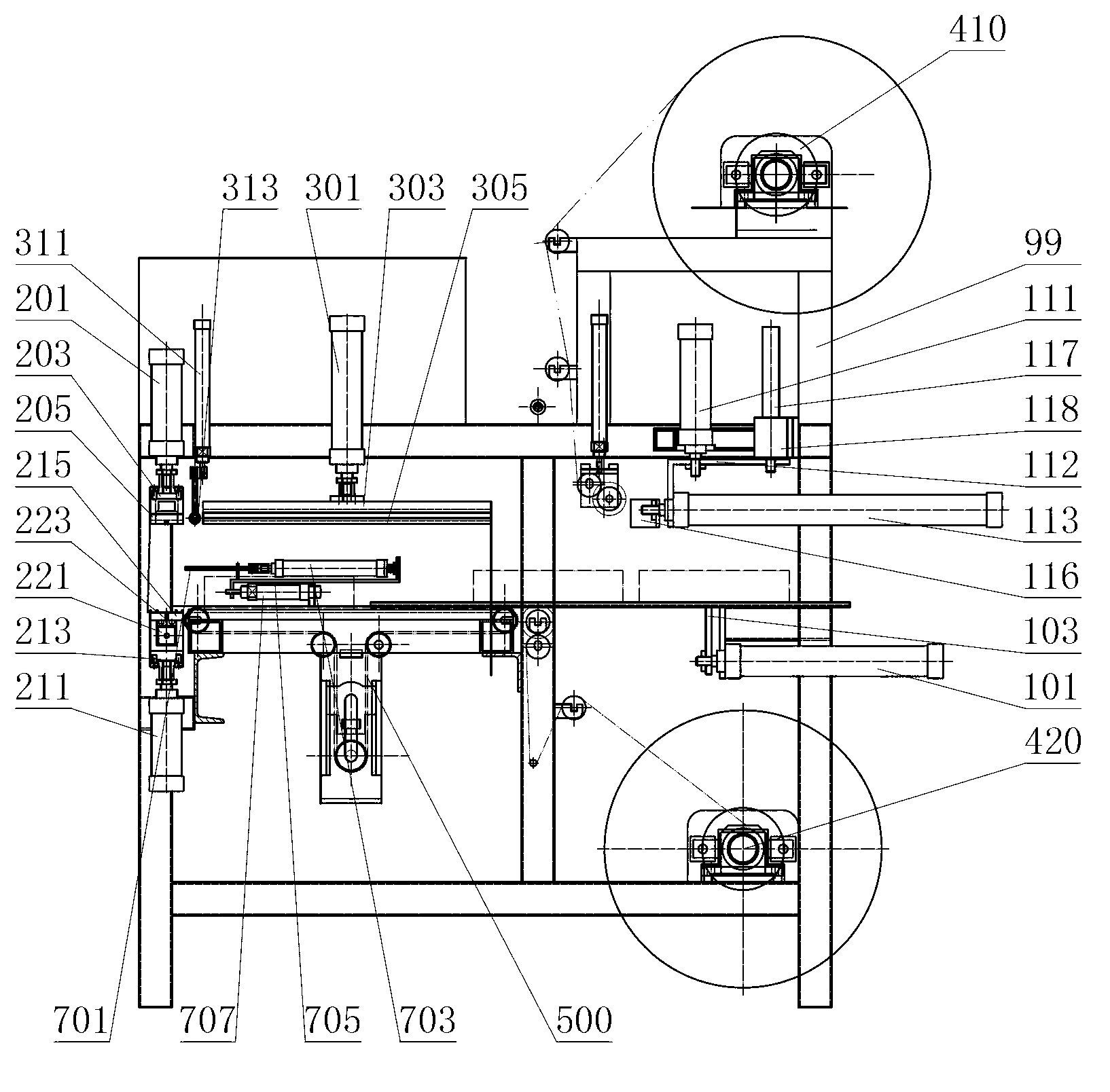

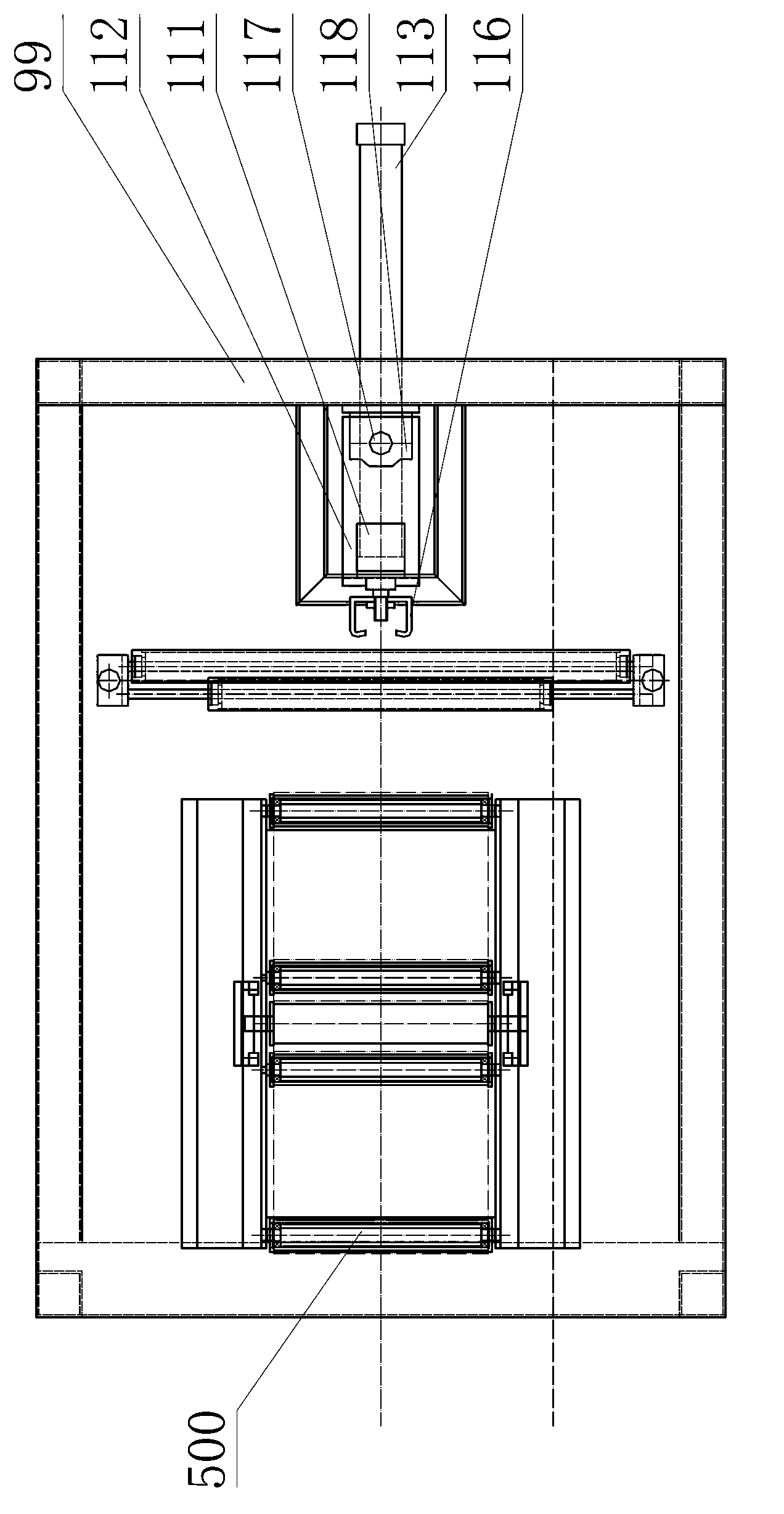

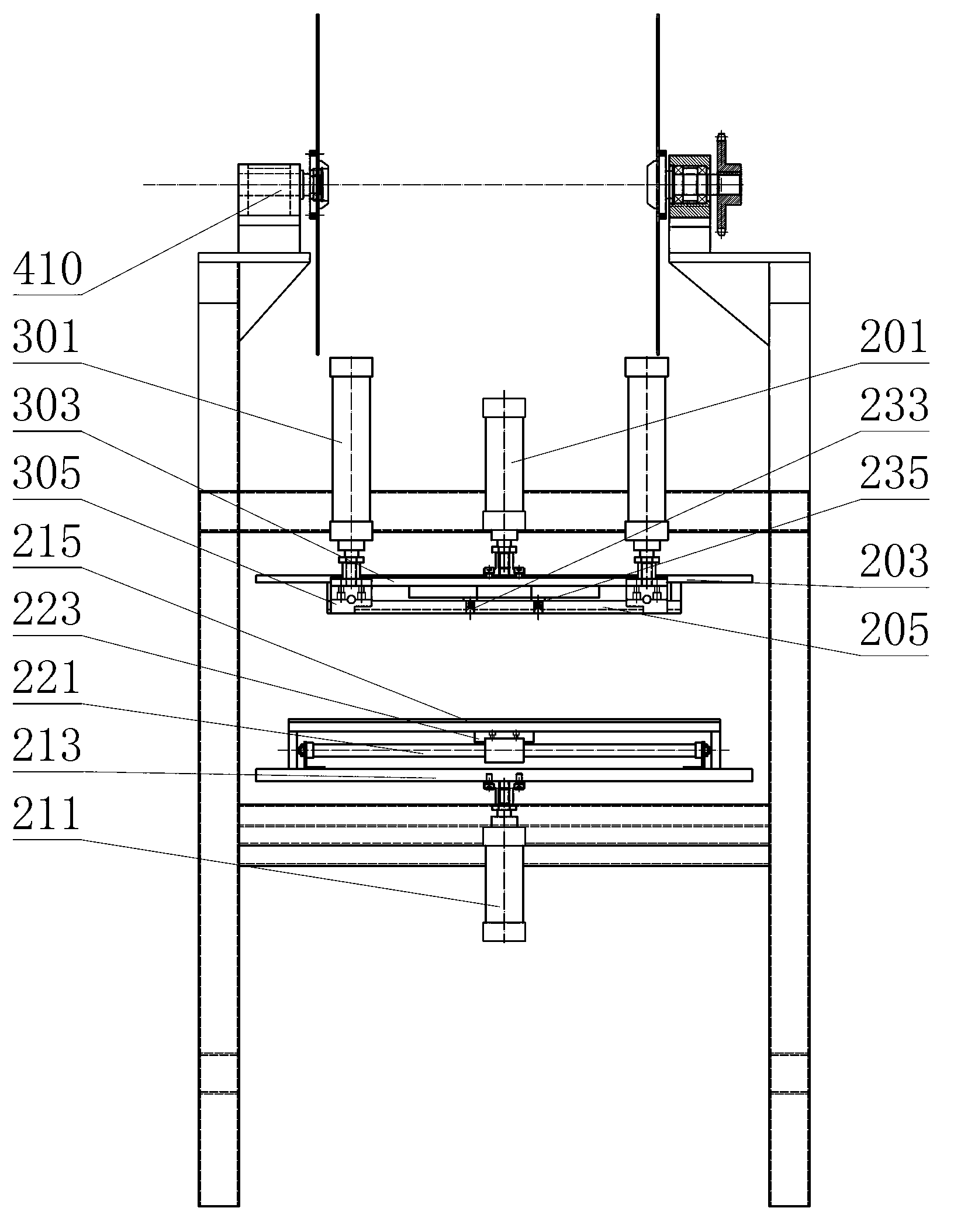

[0050] see Figure 1-3 ,

[0051] A vacuum packaging machine, including a welding wire reel feeding mechanism located at the most upstream and a finished product conveying device located at the most downstream, and also includes a film sealing device and a film supply device, the film supply device includes an upper film supply device and a lower film supply device, The upper film feeding device is located at the upper part of the frame, the lower film feeding device is located at the lower part of the frame, the film sealing device includes a front sealing film device and a side sealing film device, the front sealing film device is set at the exit of the vacuum packaging machine, the front sealing film The device is also equipped with a film cutting device, the side sealing device is arranged upstream of the front sealing device, the upstream of the front sealing device is also provided with a vacuum device, and the upstream of the front sealing device is provided with a semi...

Embodiment 2

[0076] like Figure 4 As shown, most of this embodiment is the same as Embodiment 1, the only difference is that the installation method of the lamination cylinder of the lamination device is different, including two structures:

[0077]The first type of mechanism: the film-pressing cylinder 311 is hinged at the tail or the middle part on the frame. The laminating roller 313 is still connected, and a bracket is provided under the cylinder, so that the head of the cylinder is still in the direction obliquely downward (towards the lower right in the figure) when the cylinder shrinks. At step (10) of the action principle, the laminating cylinder stretches out, and first pushes the laminating roller to move upwards to the packaging film. While the film cylinder stretches out, the lamination cylinder swings, and the lamination roller rolls to the right on the upper packaging film, thereby squeezing out the air between the upper packaging film and the lower packaging film. In step...

Embodiment 3

[0080] Most of this embodiment is the same as Embodiment 1, the only difference is that the lamination device does not compress the space between the upper packaging film and the lower packaging film through the lamination roller, and the lamination process is a belt driven by the lamination cylinder. It can be done by elastic laminating board, and the following two mechanisms can be used:

[0081] The first organization:

[0082] like Figure 5 As shown, the film-pressing cylinder 311 is fixedly connected to the frame 99, the piston rod of the film-pressing cylinder is fixedly connected to the film-pressing plate 315, and the movement of the film-pressing plate is also guided by a linear guide (the linear guide is omitted in the figure). The shape of the laminated plate can be a flat plate or a downwardly protruding arc. In step (10), when the cylinder is stretched out, the tail of the pressure film plate first touches the upper and lower packaging films, and then during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com