High-frequency induction brazing deep elbow pipe welding line polishing device

A high-frequency induction brazing and deep bending technology, which is applied in the direction of grinding machines, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of inconspicuous effect, low co-assembly efficiency, and removal of weld bumps, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

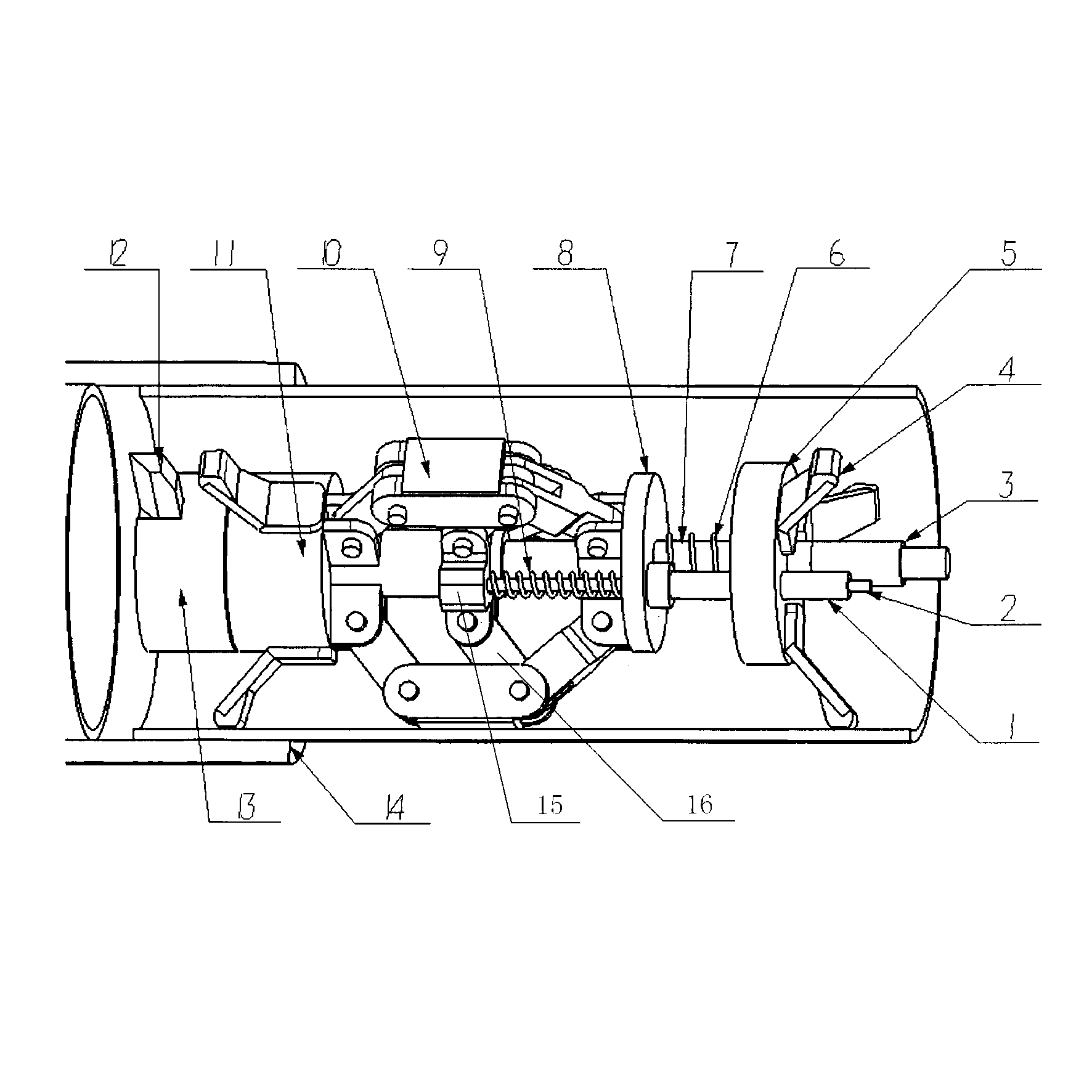

[0010] Such as figure 1 As shown, a high-frequency induction brazing deep bend pipe weld seam grinding device, one end of the bearing sleeve 11 is connected to the flexible shaft 3 through the transmission shaft 7, and the other end is connected to the clamping cutter disc 13, and the clamping cutter disc 13 is provided with a cutter 12; The bearing sleeve 11 is a stepped shaft structure, and three pairs of lugs are arranged on the stepped shaft, and the slider 8 is coaxially connected to the transmission shaft 7. The inner surface of the slider 8 has three pairs of lugs evenly distributed on the circumference. Between the bearing sleeve 11 and each group of corresponding lugs of the slider 8, a support positioning mechanism 10 of a three-link structure is connected, and a support sleeve 15 is provided on the bearing sleeve 11, and three pairs of ears distributed in a circle are also provided on the support sleeve 15. The three pairs of lugs on the support sleeve 15 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com