Compact-structure high-speed automatic right angle head small and skillful in design

A right-angle head, compact technology, applied in the direction of drive devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of not meeting the requirements, achieve the effect of improving space utilization, meeting mold processing requirements, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

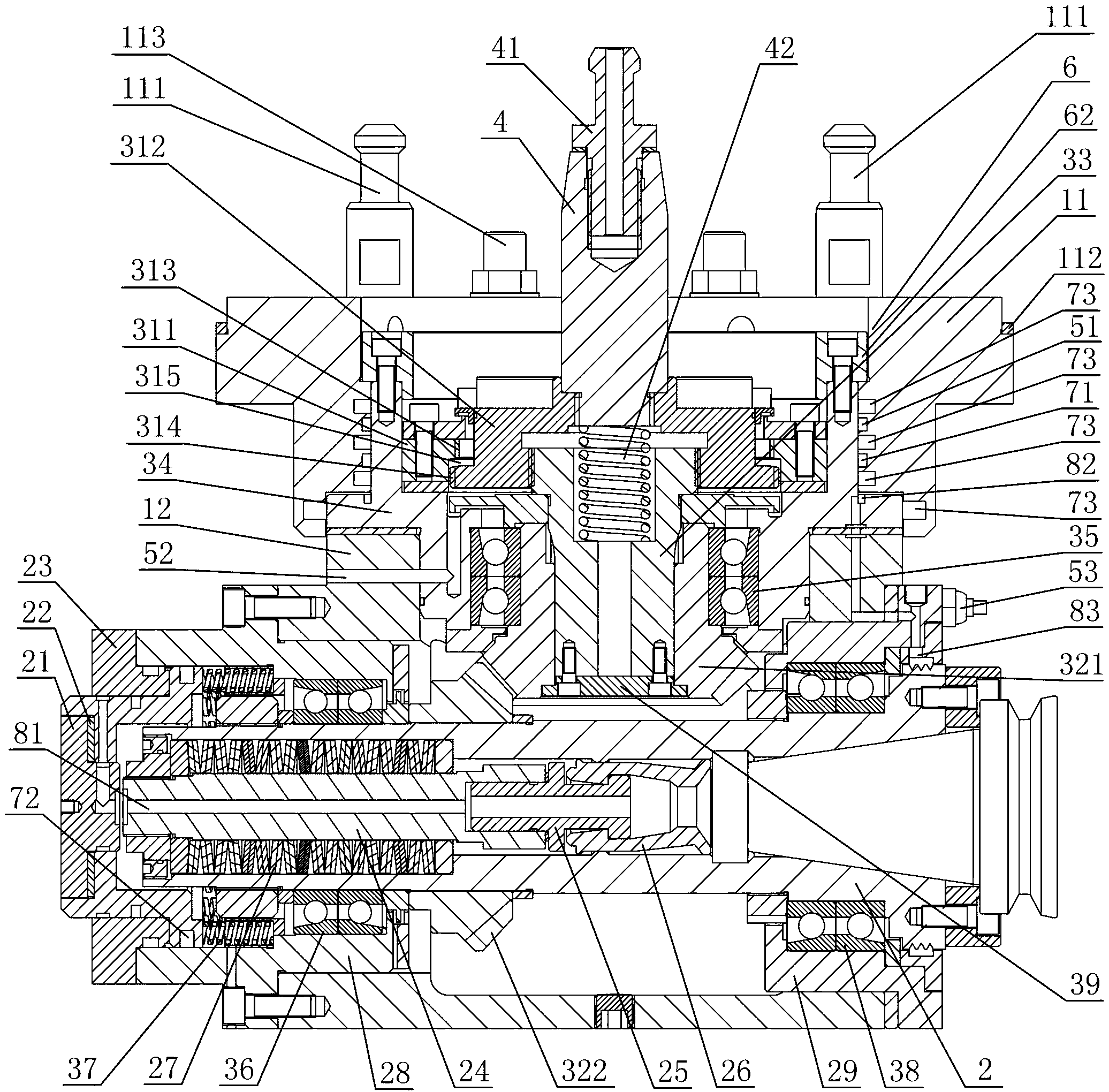

[0017] As shown in the figure, a compact high-speed automatic right-angle head includes a box body 1, a main shaft 2 and a transmission mechanism 3 arranged between the box body 1 and the main shaft 2. The box body 1 consists of an upper box body 11 and a lower box body. Composed of 12, the upper box body 11 is provided with a plurality of pull rivets 111 and quick-change joints 113, and the upper box body 11 is connected with the ram oil receiving plate (not shown in the figure) of the slider cylinder through a plurality of pull rivets 111, A square rubber ring 112 is provided at the connection between the upper box body 11 and the ram oil receiving pan; a first gland 21, a piston 22, a second gland 23, and a pull rod 24 are arranged in sequence from the rear end of the main shaft 2 to the front end of the main shaft 2 1. Pull claw fixing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com