A metal band sawing machine for cutting thin slices of wind power flanges

A technology for wind power flanges and metal strips, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., and can solve the problem that the workbench cannot be horizontally moved and the power head cannot be moved horizontally. Cutting and other issues, to achieve the effect of simple structure, low cost and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

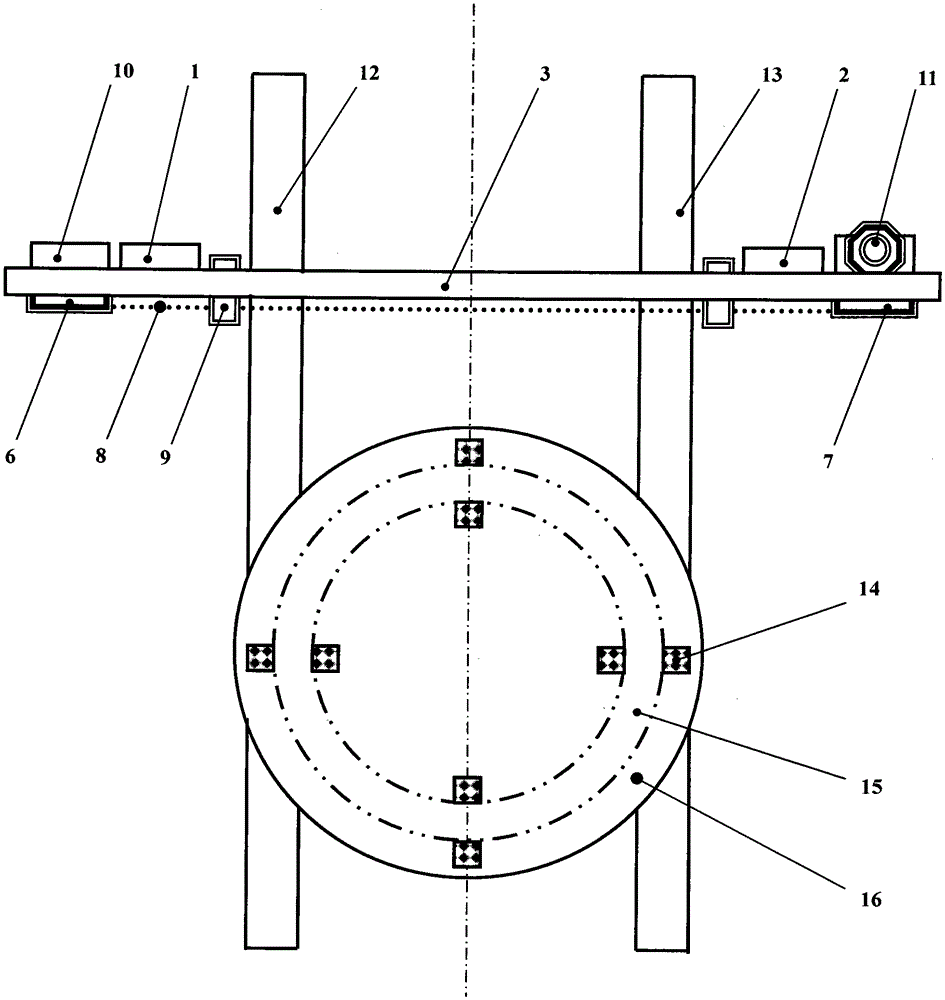

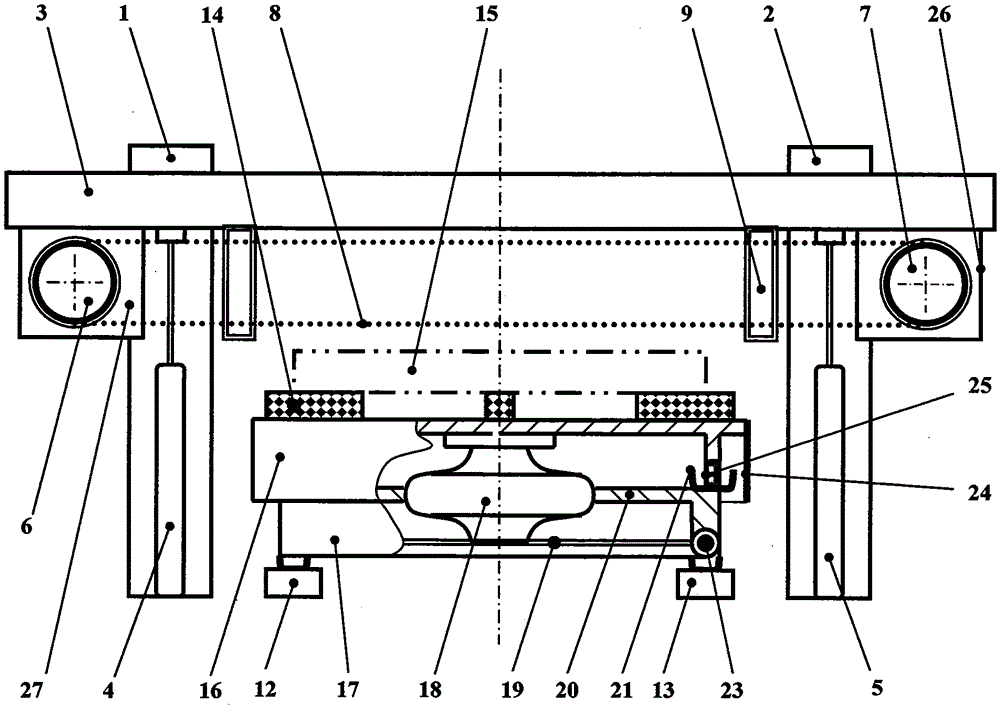

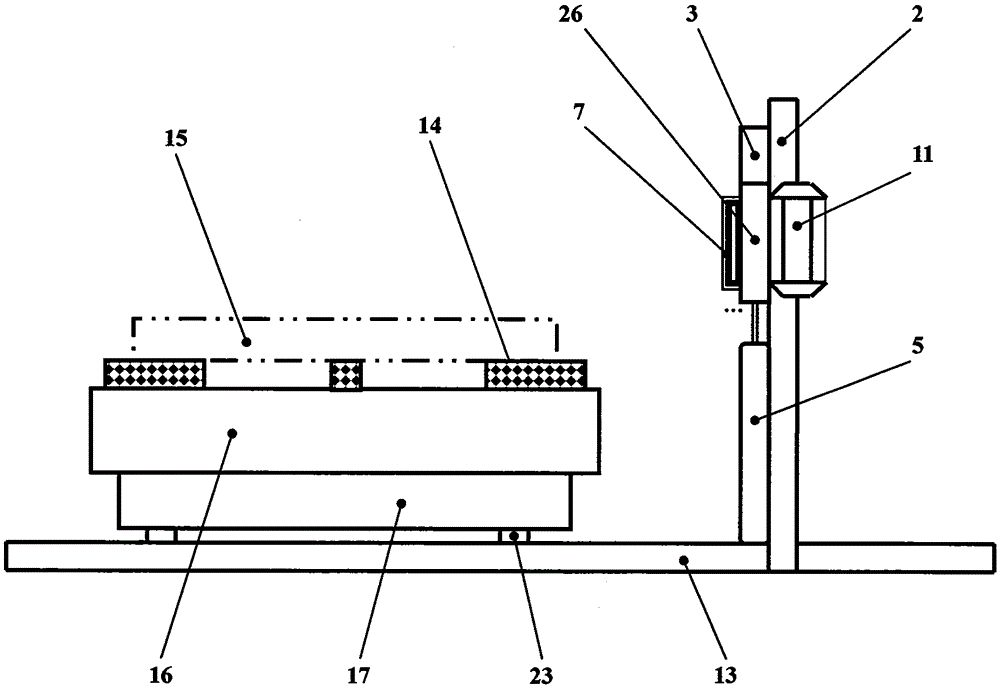

[0024] in figure 1 figure 2 image 3 In the first embodiment shown, a metal band sawing machine for cutting thin-sheet wind power flanges includes vertical gantry columns 1 and 2 with rectangular cross-sections and horizontal cross sections in front of the gantry columns 1, 2 A gantry frame formed by a rectangular moving crossbeam 3, and horizontally below the moving crossbeam 3 between the upper part of the gantry columns 1, 2 are horizontally provided with guide rails 12, 13 that are perpendicular to the gantry columns 1, 2, and the moving crossbeam 3. The two ends of the guide rails 12 and 13 are linearly extended, and are characterized by a sliding connection between the vertical gantry columns 1, 2 and the horizontal moving beam 3, and the lower part of the moving beam 3 is connected in front of the gantry columns 1, 2 Hydraulic support columns 4, 5;

[0025] A rectangular driven support base 27 is provided at the bottom of the left end of the moving beam 3 near the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com