High-permeation flux polydimethylsiloxane porous-wall micro-capsule hybrid membrane and preparation method

The technology of polydimethylsiloxane and dimethylsiloxane is applied in the fields of high-permeation flux polydimethylsiloxane porous wall microcapsule hybrid membrane and preparation, and can solve the problem of high manufacturing cost, complicated Preparation process and other problems, to achieve the effect of excellent separation performance, high reactivity, and controllable microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

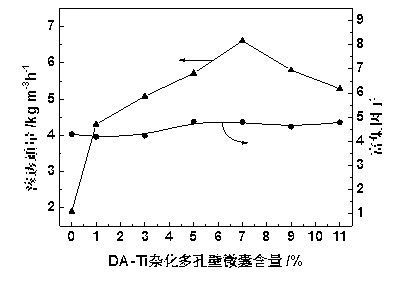

Examples

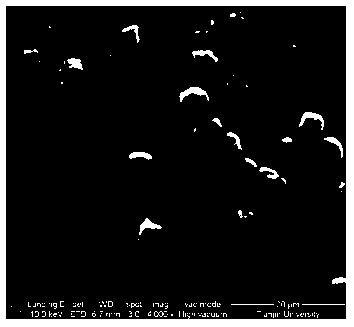

Embodiment 1

[0027] Prepare a solution with 3.50 g of anhydrous sodium carbonate and 100 ml of deionized water, and prepare a solution of 4.85 g of calcium chloride dihydrate with 100 ml of deionized water. In the process of vigorous stirring, the sodium carbonate solution was quickly poured into the calcium chloride solution, continued to stir for 30 s, and then stood still for 30 min, centrifuged and washed repeatedly with deionized water to obtain the calcium carbonate template. The prepared calcium carbonate template was dispersed into 100 ml of 0.02 mol / L Ti-BALDH solution, stirred for 2 h, centrifuged and washed repeatedly with deionized water. The resulting solid particles were added to 100 ml of hydrochloric acid-Tris acid-base buffer solution with a pH value of 7.5, a dopamine concentration of 8 g / L, and a Tris concentration of 6.06 g / L, and stirred for 30 min to obtain titanium oxide-dopamine-calcium carbonate particles. Prepare 400ml, 18.62 g / L EDTA solution, and adjust the pH ...

Embodiment 2

[0030] Prepare a solution with 3.50 g of anhydrous sodium carbonate and 100 ml of deionized water, and prepare a solution of 4.85 g of calcium chloride dihydrate with 100 ml of deionized water. In the process of vigorous stirring, the sodium carbonate solution was quickly poured into the calcium chloride solution, continued to stir for 30 s, and then stood still for 30 min, centrifuged and washed repeatedly with deionized water to obtain the calcium carbonate template. The prepared calcium carbonate template was dispersed into 100 ml of 0.02 mol / L Ti-BALDH solution, stirred for 2 h, centrifuged and washed repeatedly with deionized water. The resulting solid particles were added to 100 ml of hydrochloric acid-Tris acid-base buffer solution with a pH value of 7.5, a dopamine concentration of 8 g / L, and a Tris concentration of 6.06 g / L, and stirred for 30 min to obtain titanium oxide-dopamine-calcium carbonate particles. Prepare 400ml, 18.62 g / L EDTA solution, and adjust the pH ...

Embodiment 3

[0033]Prepare a solution with 3.50 g of anhydrous sodium carbonate and 100 ml of deionized water, and prepare a solution of 4.85 g of calcium chloride dihydrate with 100 ml of deionized water. In the process of vigorous stirring, the sodium carbonate solution was quickly poured into the calcium chloride solution, continued to stir for 30 s, and then stood still for 30 min, centrifuged and washed repeatedly with deionized water to obtain the calcium carbonate template. The prepared calcium carbonate template was dispersed into 100 ml of 0.02 mol / L Ti-BALDH solution, stirred for 2 h, centrifuged and washed repeatedly with deionized water. The resulting solid particles were added to 100 ml of hydrochloric acid-Tris acid-base buffer solution with a pH value of 7.5, a dopamine concentration of 8 g / L, and a Tris concentration of 6.06 g / L, and stirred for 30 min to obtain titanium oxide-dopamine-calcium carbonate particles. Prepare 400ml, 18.62 g / L EDTA solution, and adjust the pH v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enrichment factor | aaaaa | aaaaa |

| enrichment factor | aaaaa | aaaaa |

| enrichment factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com