Full-automatic base material tray charging mechanism

A substrate loading and fully automatic technology, applied in application, cultivation, agriculture, etc., can solve the problems of large labor costs, small feeding bin volume, high production costs, etc., and achieve the goal of reducing feeding times, reducing labor intensity, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

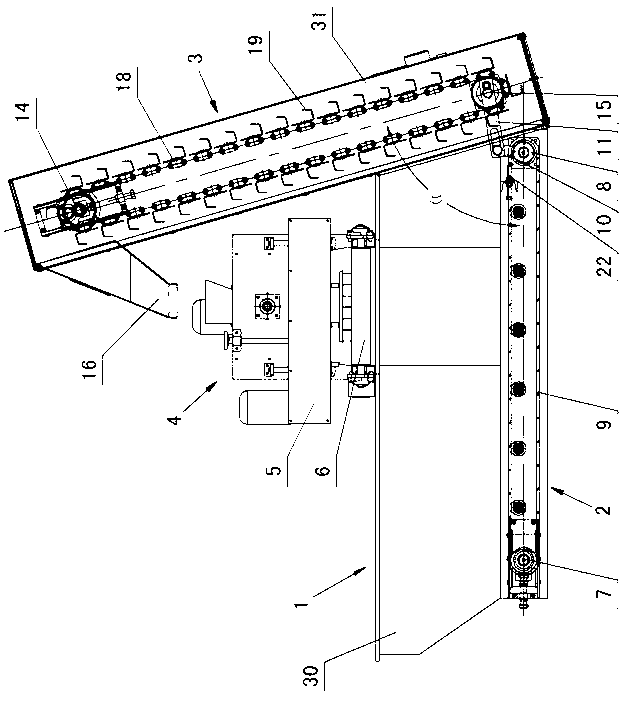

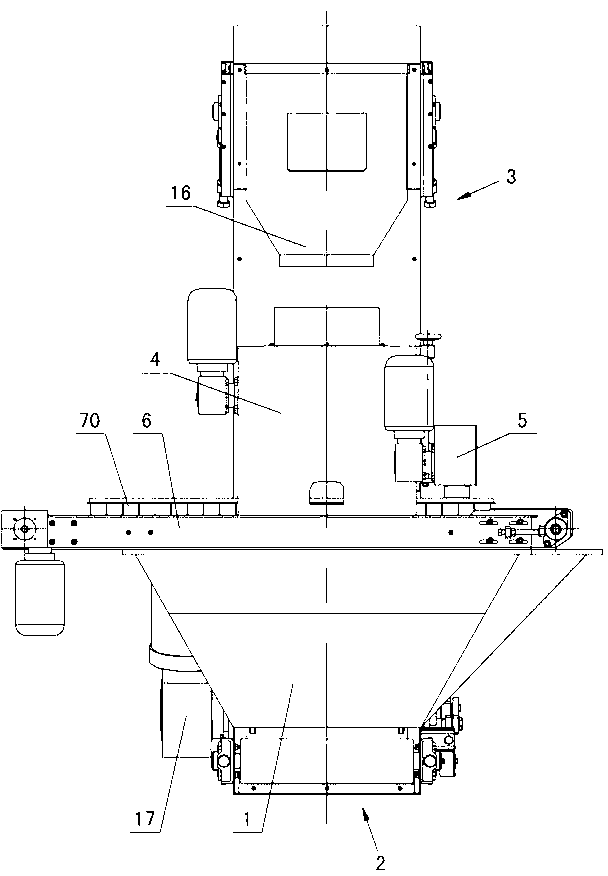

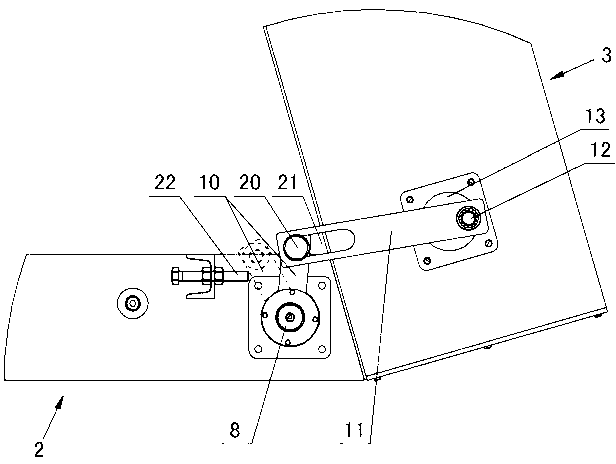

[0014] The invention relates to a fully automatic matrix loading mechanism, such as figure 1 — Figure 7 As shown, it includes a feeding bin 1, a horizontal feeding system 2, an oblique feeding system 3, a substrate breaking up system 4, a substrate brushing system 5 and a workbench 6 for setting seedling trays, and is characterized in that: the feeding bin One end of 1 is provided with a feeding port 30, and the oblique feeding system 3 is arranged at the other end of the feeding bin 1, and the horizontal feeding system 2 includes setting a left rotating shaft 7 and a one-way shaft 8 in the feeding bin, turning left A conveyor belt 9 is arranged on the moving shaft and the one-way shaft, and one side of the one-way shaft is connected to the inclined conveying system 3 through a linkage mechanism. Sub 20 is connected to one end of connecting rod 11, and the other end of connecting rod is opened with connecting hole 24, and connecting pin 12 is installed in the connecting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com