Resin composition, phase-ontrast film, method for manufacturing phase-contrast film, and long circularly-polarizing plate

A technology of resin composition and retardation film, applied in polarizing elements, instruments, optics, etc., can solve the problems of difficulty in large area, low manufacturing efficiency, waste, etc., and achieve easy manufacturing, excellent heat resistance and transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] Hereinafter, the present invention will be specifically described by showing examples, but the present invention is not limited to the following examples, and can be implemented with any changes within the scope not departing from the claims of the present invention and their equivalents.

[0130] [explanation of evaluation method]

[0131] (Measuring method of glass transition temperature)

[0132] The glass transition temperature of the resin composition was measured by heating up at 20°C / min using a differential scanning calorimeter (EXSTAR6220 manufactured by Seiko Instruments).

[0133] (Measurement method of haze)

[0134] According to JIS K7361-1997, haze was measured at 5 places using the "nephelometer NDH-300A" by Nippon Denshoku Industries Co., Ltd., and it calculated|required from the average value.

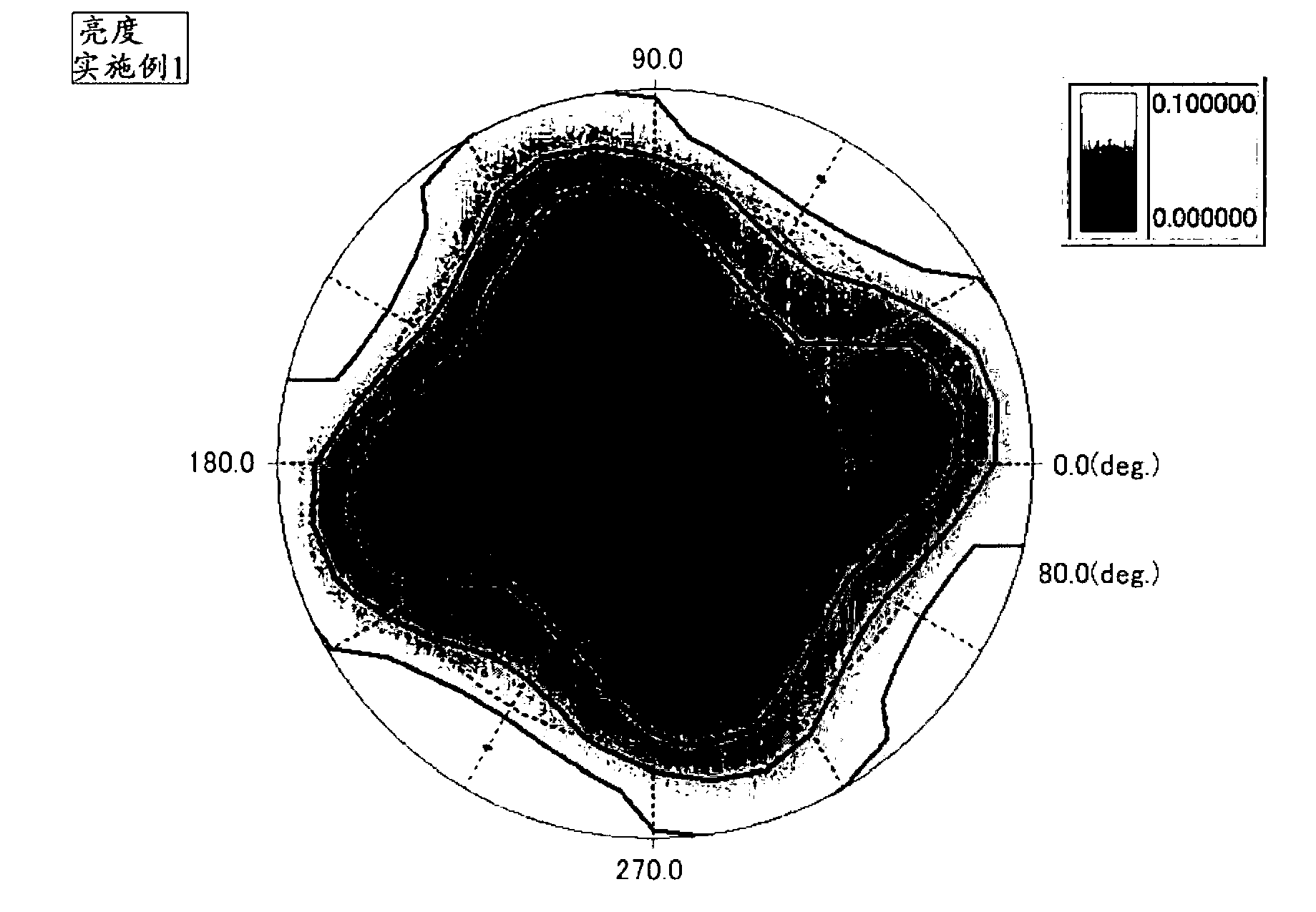

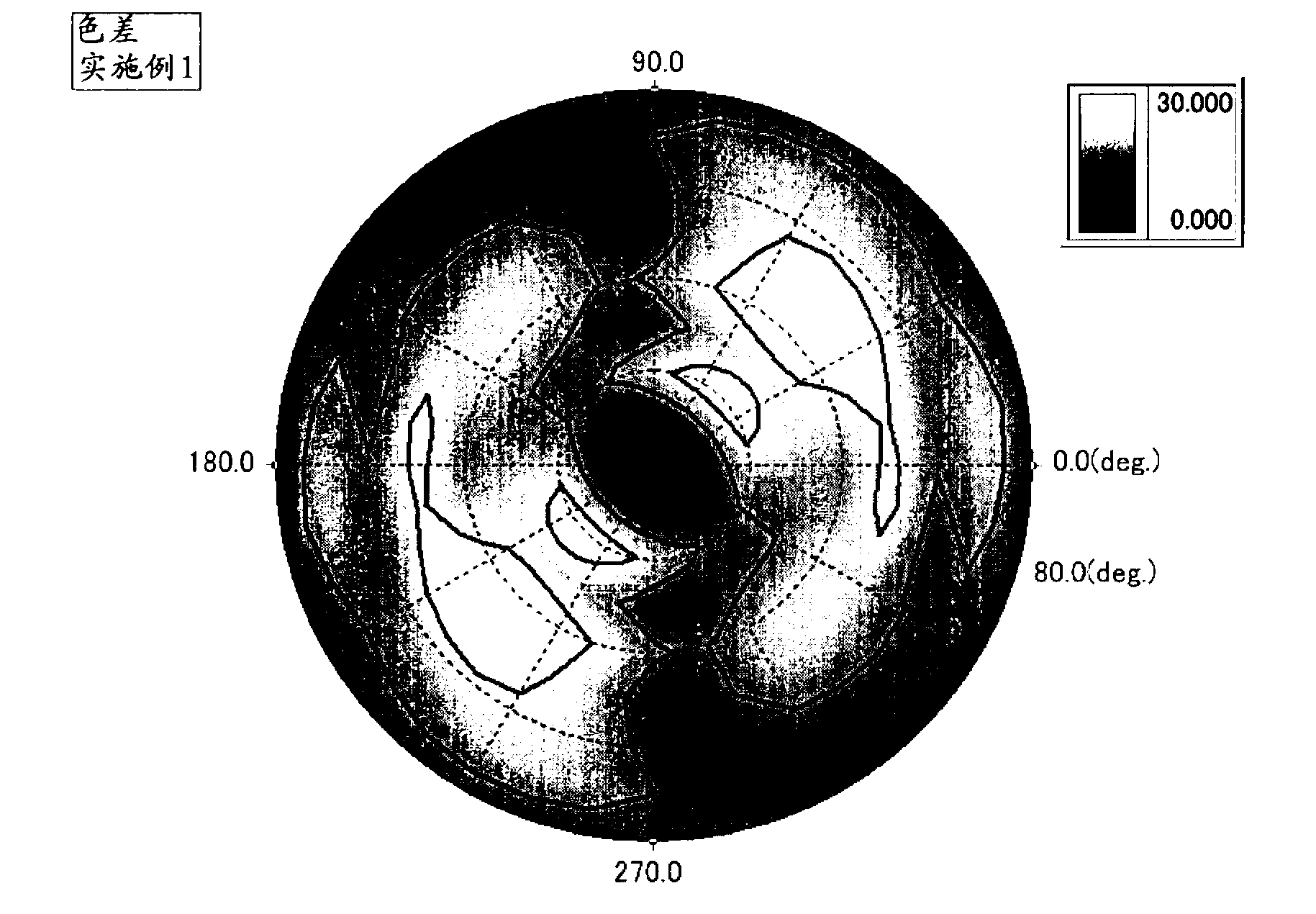

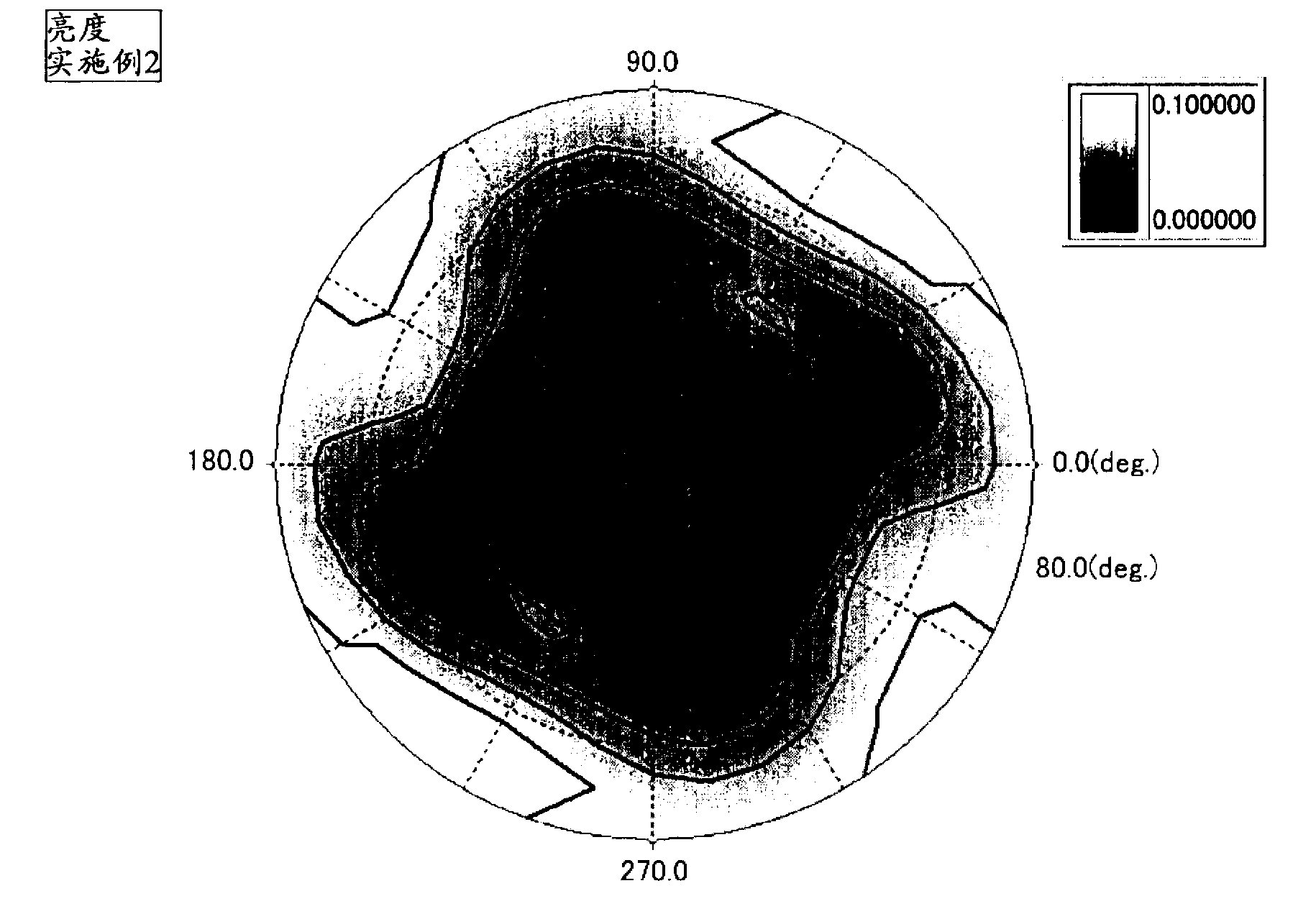

[0135] (Re 450 、Re 550 and Re 650 , Nz450, Nz550 and Nz650 determination method)

[0136] Using AxoScan manufactured by AXOMETRICS, the in-plane direction...

manufacture example 1

[0142] [Manufacture Example 1: Manufacture of Styrene-Maleic Anhydride Copolymer B1]

[0143] A complete mixing reactor with a stirrer, a tower plug flow reactor, and a devolatilization tank with a preheater are connected in series to form a manufacturing device. 85 parts by mass of styrene, 15 parts by mass of maleic anhydride, 0.02 parts by mass of 1,1-bis(t-butylperoxy)-cyclohexane, and 0.2 parts by mass of n-dodecylmercaptan were mixed to prepare a raw material solution. This raw material solution was introduced into a complete mixing type reactor controlled at a temperature of 130° C., and stirred at 180 rpm. Next, the reaction liquid is continuously withdrawn from the fully mixed reactor and introduced into a tower-type plug-flow reactor, which is adjusted to have a temperature of 130°C to 160°C along the liquid flow direction. temperature gradient. This reaction solution was introduced into a devolatilizer controlled at a temperature of 235° C. and a pressure of 1.0 k...

manufacture example 2

[0144] [Manufacture example 2: Manufacture of styrene-maleic anhydride copolymer B2]

[0145]Except having adjusted the quantity of styrene to 90 mass parts, and the quantity of maleic anhydride to 10 mass parts, it carried out similarly to manufacture example 1, and manufactured the styrene-maleic anhydride copolymer B2. The obtained styrene-maleic anhydride copolymer B2 contained 92% by weight of styrene units and 8% by weight of maleic anhydride units. In addition, the glass transition temperature of the styrene-maleic anhydride copolymer B2 was 102°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com