AOI (Automated Optical Inspection) digital LED (Light-Emitting Diode) light source controller and control method thereof

A technology of LED light source and control method, applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of insufficient image contrast, enlarged aperture, insufficient light source brightness, etc., and achieve the effect of clear image and precise brightness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

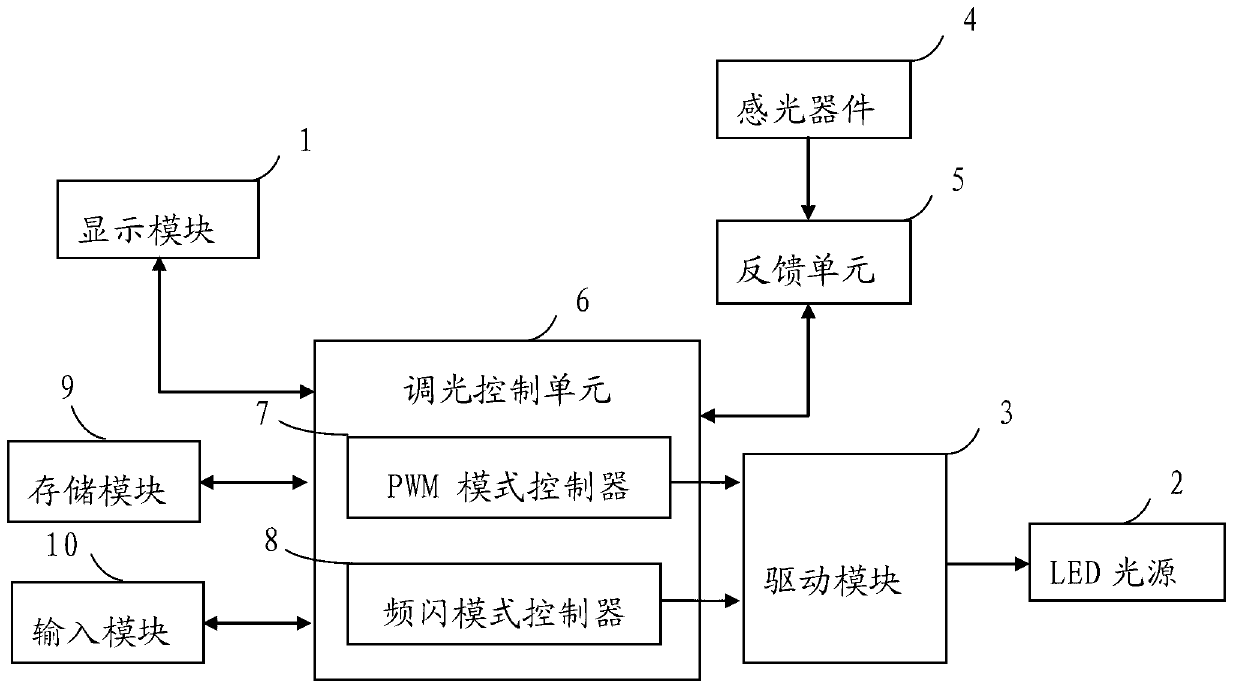

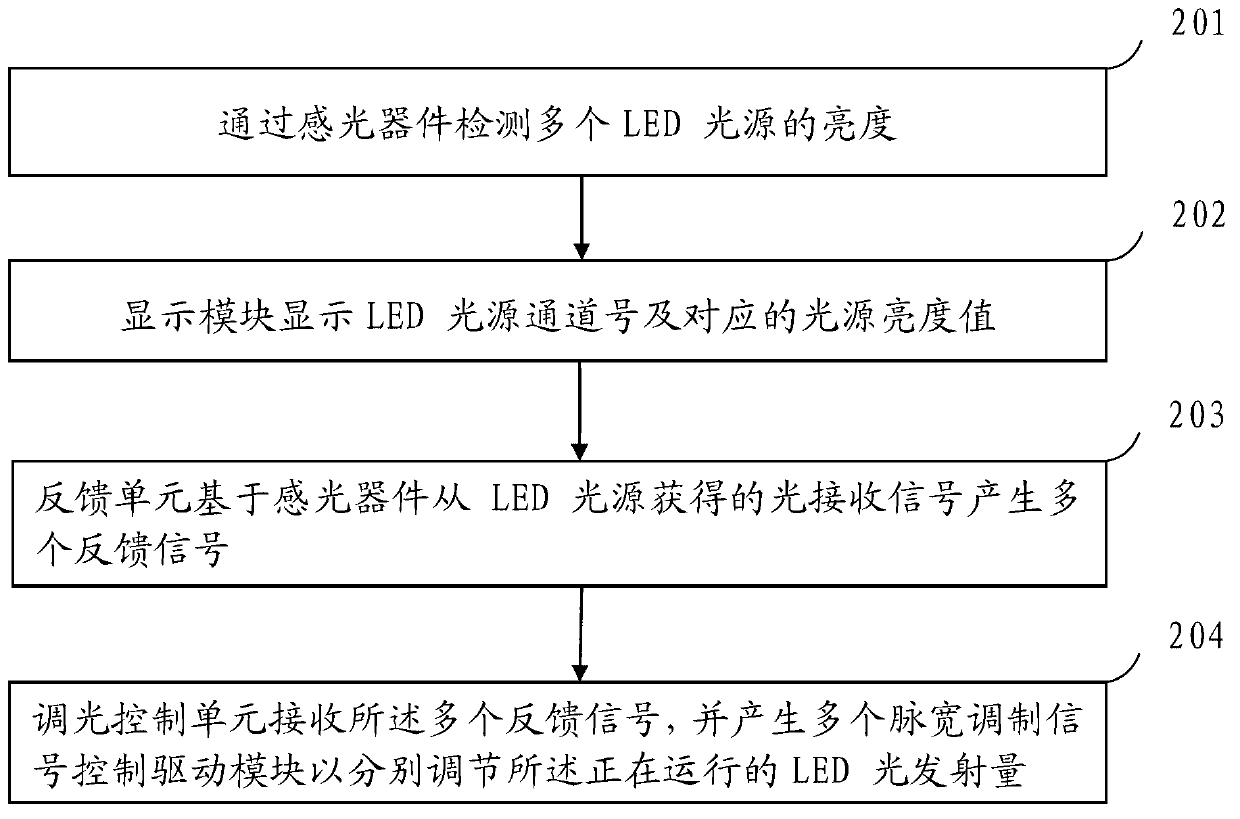

[0036] Such as figure 1 As shown, this embodiment provides an AOI digital LED light source controller, including:

[0037] The display module 1 is used to display the channel number of the LED light source 2 and the corresponding light source brightness value; the driving module 3 is used to drive the light source so that multiple LED light sources 2 are turned on sequentially; the photosensitive device 4 is used to receive signals from the sequentially turned on multiple LED light sources 2 light; the feedback unit 5 is used to generate a plurality of feedback signals based on the light receiving signal obtained by the photosensitive device 4 from the LED light source 2; the dimming control unit 6 is used to receive the plurality of feedback signals and generate a plurality of The pulse width modulation signal controls the driving module 3 to adjust the light emission of the running LEDs respectively, the photosensitive device 4 is connected to the feedback unit 5, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com