Visualization experiment device for deep cryogenic two-phase countercurrent process

A countercurrent process and experimental device technology, applied in measuring devices, fluid dynamics tests, instruments, etc., can solve problems such as the inability to observe the flow state of deep and low temperature fluids, and achieve the effect of solving pipeline sealing failure and wide temperature adaptation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

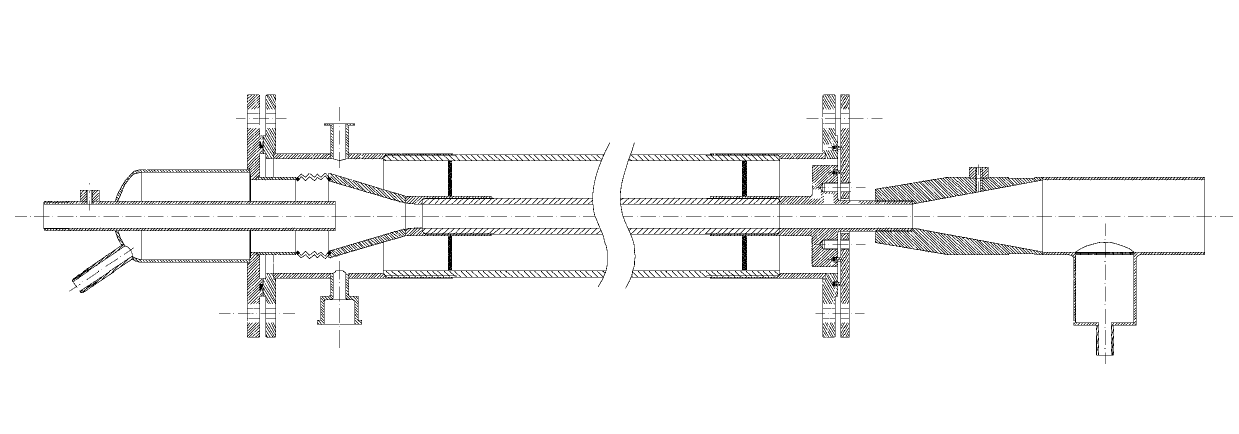

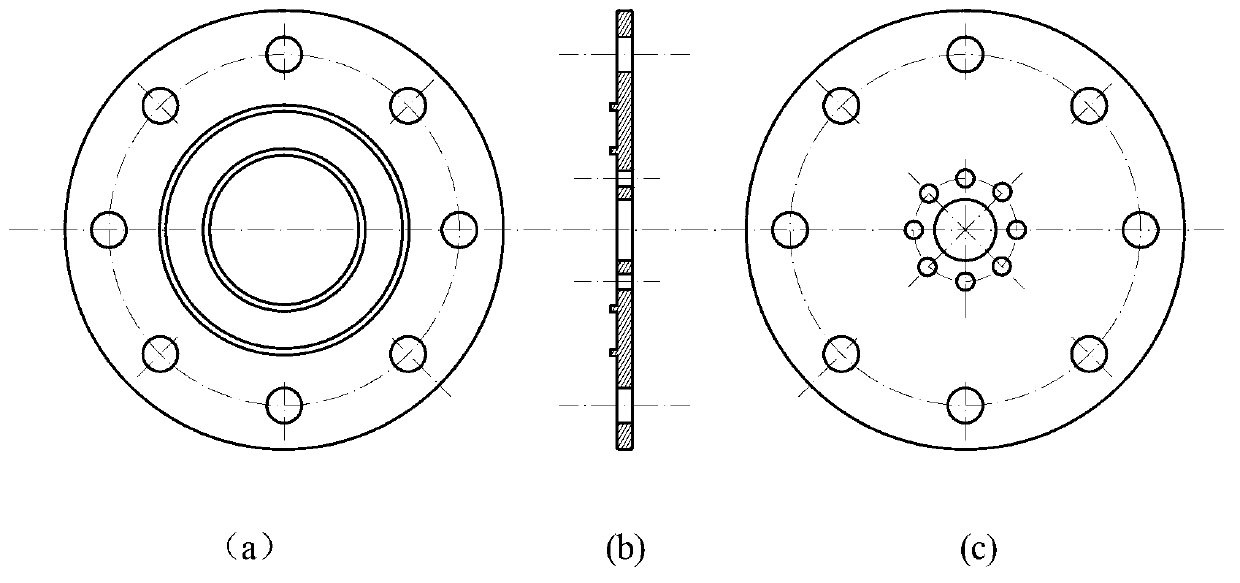

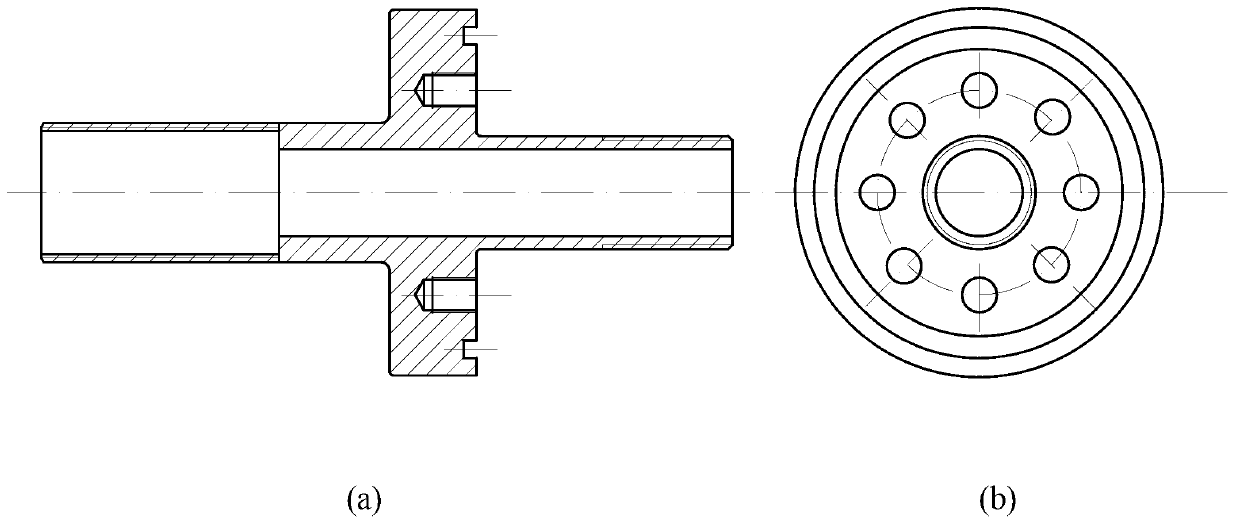

[0028] Such as figure 1 As shown, the visualization experimental device for the deep-low temperature two-phase countercurrent process includes a liquid collection section, a test section, a lower end surface Teflon gasket 5, a flange plate 19, a liquid inlet cone tube 20, and a Teflon gasket on the upper flange of the outer pipe. 23. Teflon gasket 24 of the connecting member on the small tube;

[0029] The liquid collection section includes a gas inlet pipe 1, a first pressure sensor 2, a liquid collector housing 3, an inner pipe lower flange 4, a liquid outlet pipe 26, and a transition piece 28. One end of the liquid collector housing 3 is provided with a head, The head is provided with a liquid outlet pipe 26, and the center of the liquid collector shell 3 is provided with a gas inlet pipe 1, which is fixed with the head of the liquid collector shell 3, and the other end of the liquid collector shell 3 is connected to the lower flange of the inner pipe. 4 are connected on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com