Aperture measuring method based on non-contacting type sensor combination

A measurement method and non-contact technology, applied in the field of geometric measurement, can solve the problem of not solving the aperture measurement method at the same time, and achieve the effects of saving measurement man-hours, improving measurement accuracy, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 101: First install the main shaft of the dual-sensor probe on a mechanism with a translation function to form a complete measurement system and place it in the workpiece to be measured;

[0052] During measurement, the measurement optical axes of the two sensors on the dual-sensor probe are required to be on a straight line, that is, the two measurement laser beams are collinear. This measurement method does not rely on a certain type of dual-sensor probe, as long as it is a dual-sensor probe that can realize the above-mentioned functions in the art.

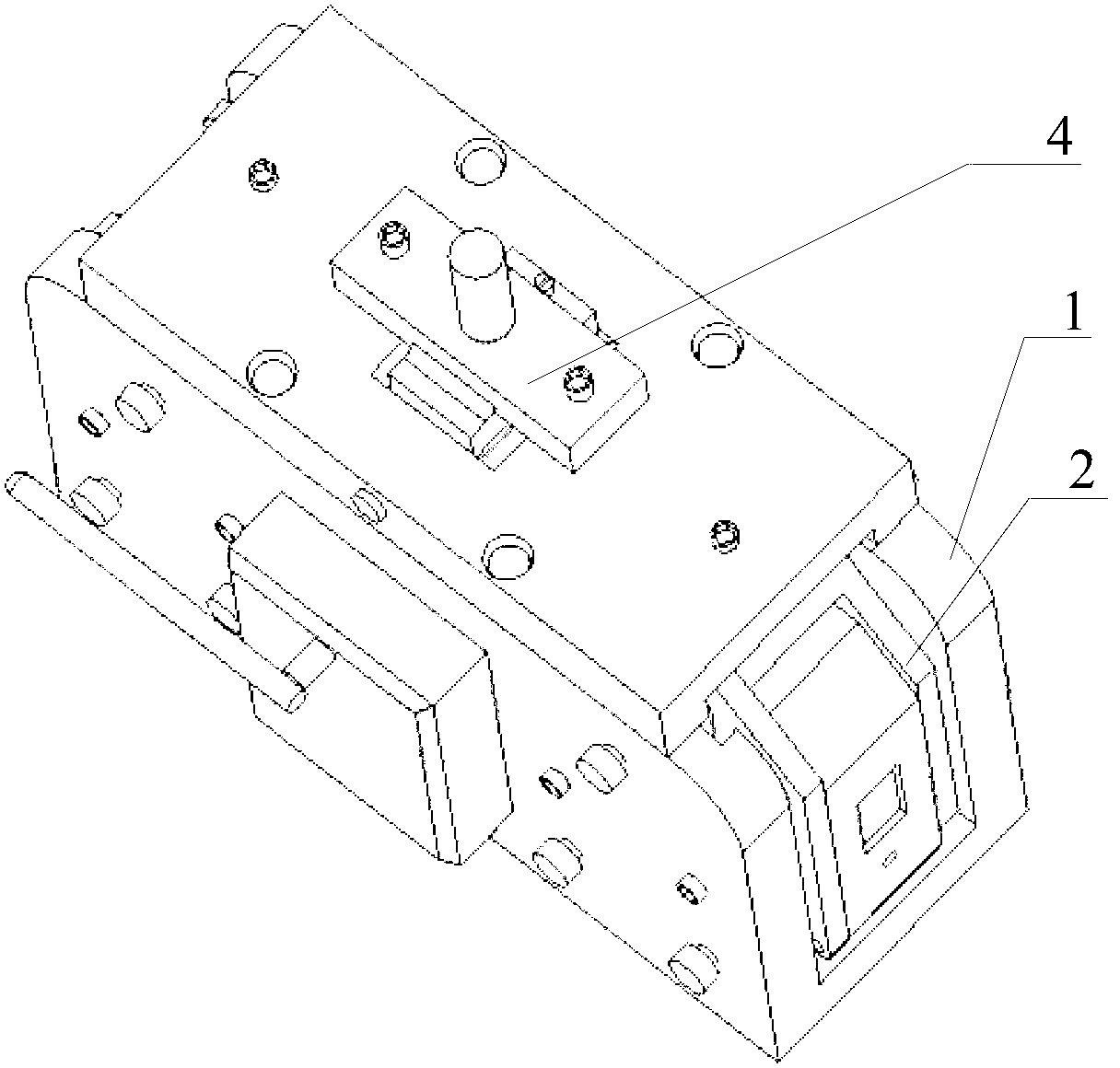

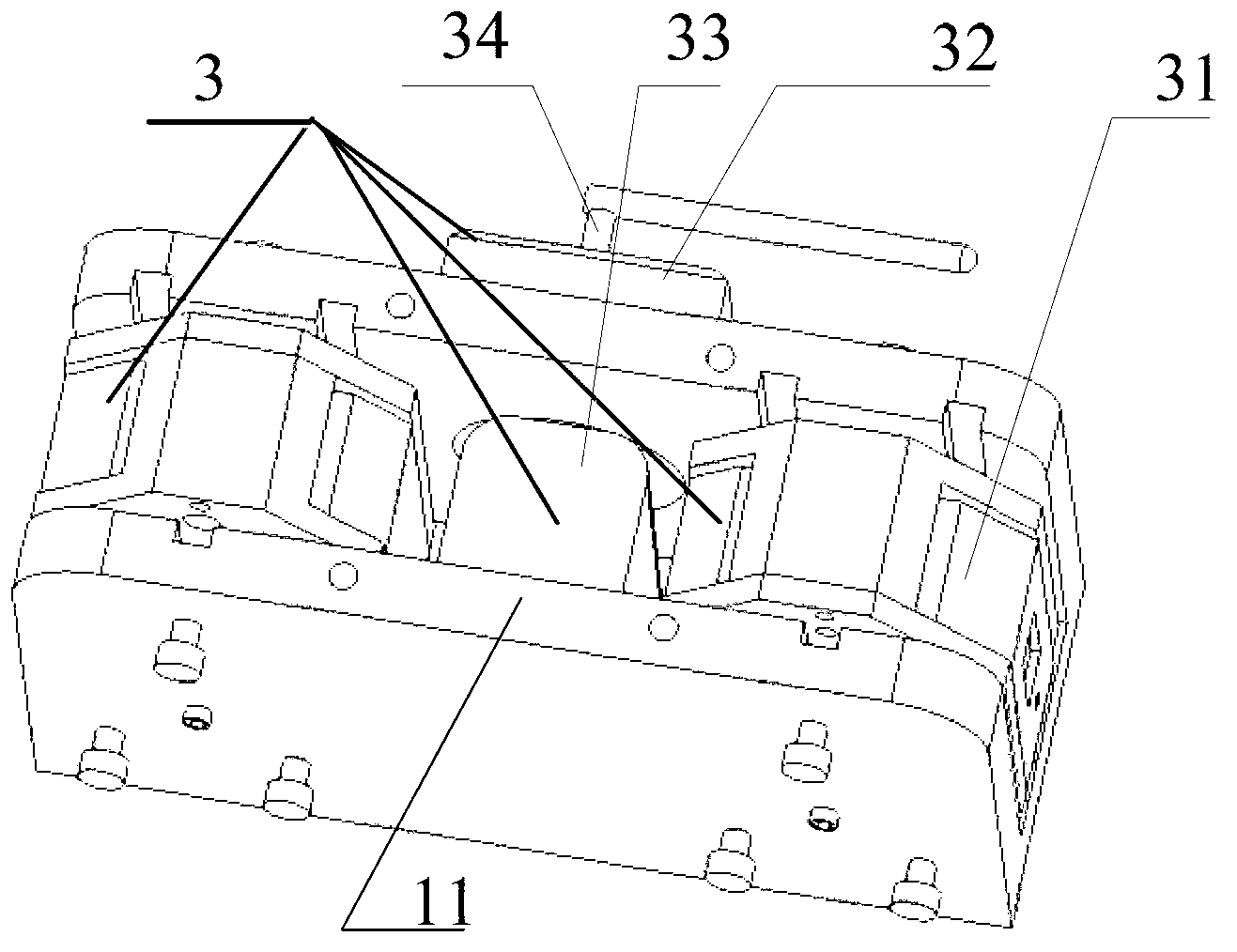

[0053] The dual-sensor measuring head adopted in the embodiment of the present invention is given below, and the dual-sensor measuring head comprises: a measuring probe frame 1, a moving frame 2, a measuring device 3 and a connecting part 4 are arranged on the measuring probe frame 1,

[0054] The probe frame 1 includes: a U-shaped groove 11, one side of the U-shaped groove 11 is provided with 4 first adjustment keys 12, ...

Embodiment 2

[0062] 201: First, install the main shaft of the dual-sensor probe on a mechanism with a translation function to form a complete measurement system and place it in the workpiece to be measured;

[0063] 202: The dual-sensor measuring head rotates on the ZOY surface and the XOY surface successively to obtain the inner hole diameter of the workpiece to be measured.

[0064] As described in Embodiment 1, after the dual-sensor measuring head rotates on the ZOY plane, the measuring optical axis can be adjusted to a plane parallel to the XOY plane. When the dual-sensor probe rotates on the parallel plane of the XOY plane, that is, the dual-sensor probe rotates around the Z-axis, the measurement data will still change from small to large and then from large to small. Next, analyze whether the measured maximum value is the inner hole diameter of the workpiece to be tested.

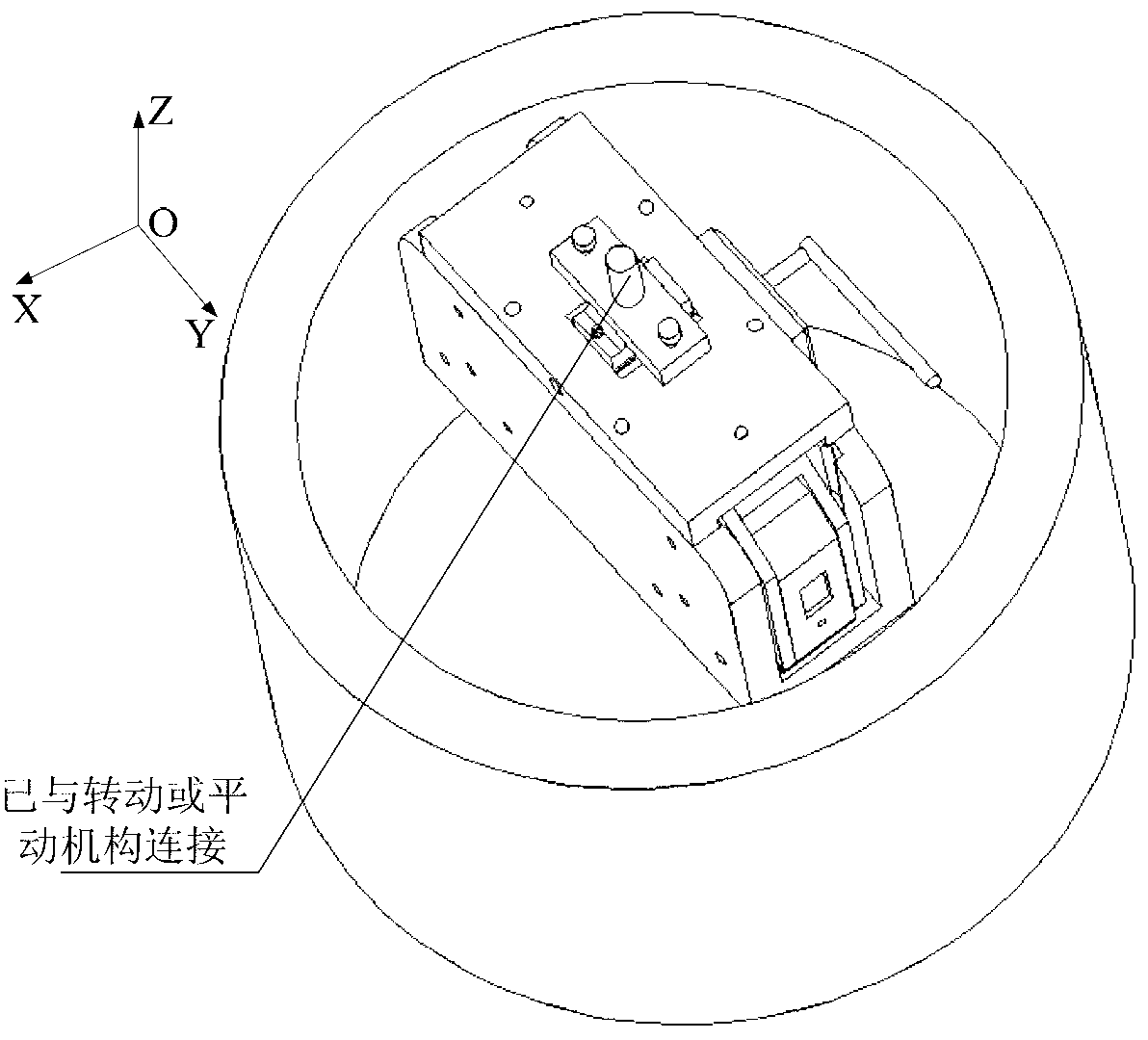

[0065] The schematic diagram of the dual-sensor probe rotating on the XOY plane is shown in Figure 3. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com