Vacuum tube joint threaded connection component

A threaded connection and component connection technology, which is applied in the direction of pipes/pipe joints/fittings, sealing surface connection, passing components, etc., can solve the problems of low flight safety factor and high maintenance cost of aerospace vehicles, and achieve fast and simple production and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the drawings and embodiments. But it is not used as a basis for any limitation of the present invention.

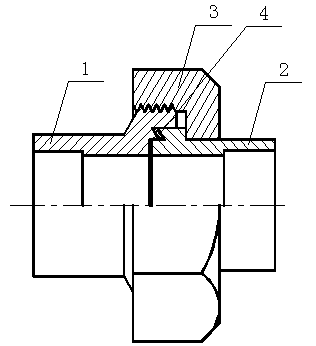

[0022] Such as figure 1 As shown, the present invention provides a vacuum pipe joint threaded connection assembly, which includes: a main vacuum pipe joint 1, a secondary vacuum pipe joint 2, a lock nut 3 and a concentric sealing ring 4.

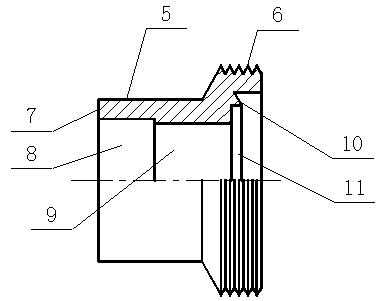

[0023] Such as figure 2 As shown, the main vacuum pipe joint 1 includes an outer pipe surface 5, a locking external thread 6, a welding end 7, a welding cavity 8, a main through cavity 9, a sealing cavity 10 and a positioning cavity 11. The external locking thread 6 engages with the internal locking thread 20 of the locking nut 3; the welding end 7 and the welding cavity 8 are welded to the vacuum tube 26 to be connected as a whole; the concentric sealing ring 4 is located in the sealing cavity 10; the positioning cavity 11 is used for the main Positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com