Double-sealing-pair metal sealing butterfly valve

A metal seal and double seal technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of poor reverse sealing performance, inability to apply high-pressure bidirectional sealing medium pipelines, leakage of sealing pairs, etc., and achieve good bidirectional sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

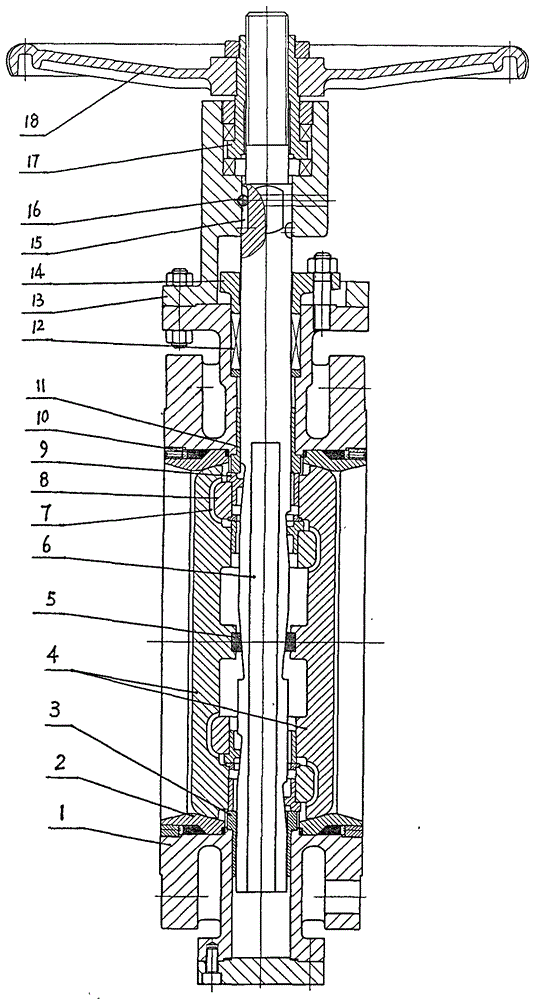

[0010] Such as figure 1 The double-seal metal-sealed butterfly valve shown includes a valve body 1, a valve stem 6, a valve seat 2, a butterfly plate 4, a bracket 13, and a handwheel 18. The upper end of the valve stem 6 is connected to the handwheel 18 through a valve stem nut 17. The valve The rod nut 17 is installed in the bracket 13 by bearings, the butterfly plate 4 is installed on the lower part of the valve stem 6, and the butterfly plate 4 is made with a sealing curved surface that cooperates with the valve seat 2; a valve seat 2 is installed in the inlet and outlet channels of the valve body 1 respectively. , double butterfly plates 4 are installed on both sides of the valve stem 6, and the butterfly plates 4 on both sides cooperate with the inlet and outlet valve seats 2 to form a sealing pair, the inlet side valve seat and the inlet side butterfly plate cooperate with each other to form a reverse sealing pair, and the outlet side The valve seat and the butterfly pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com