Hydraulic-bag-type large-diameter square pipe culvert gate and using method thereof

A large-diameter gate technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as complex opening and closing structures, high water head loss, and unsatisfactory airtightness, achieving good airtightness, less water head loss, and The effect of small water head loss when passing the sluice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

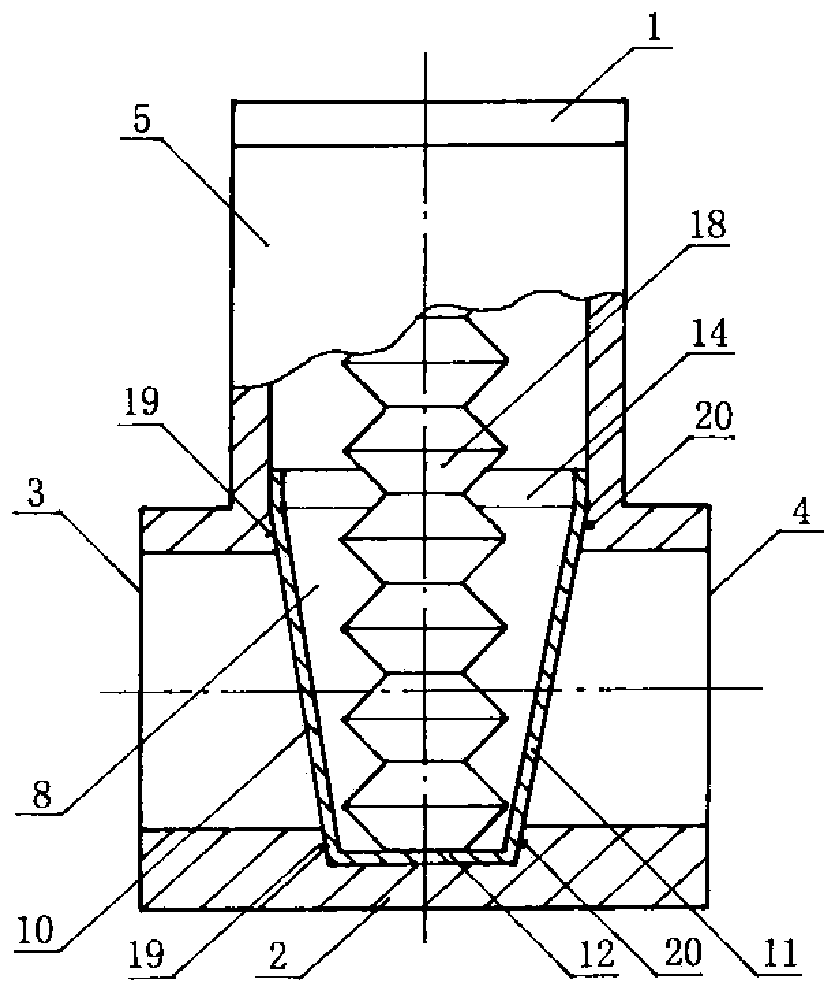

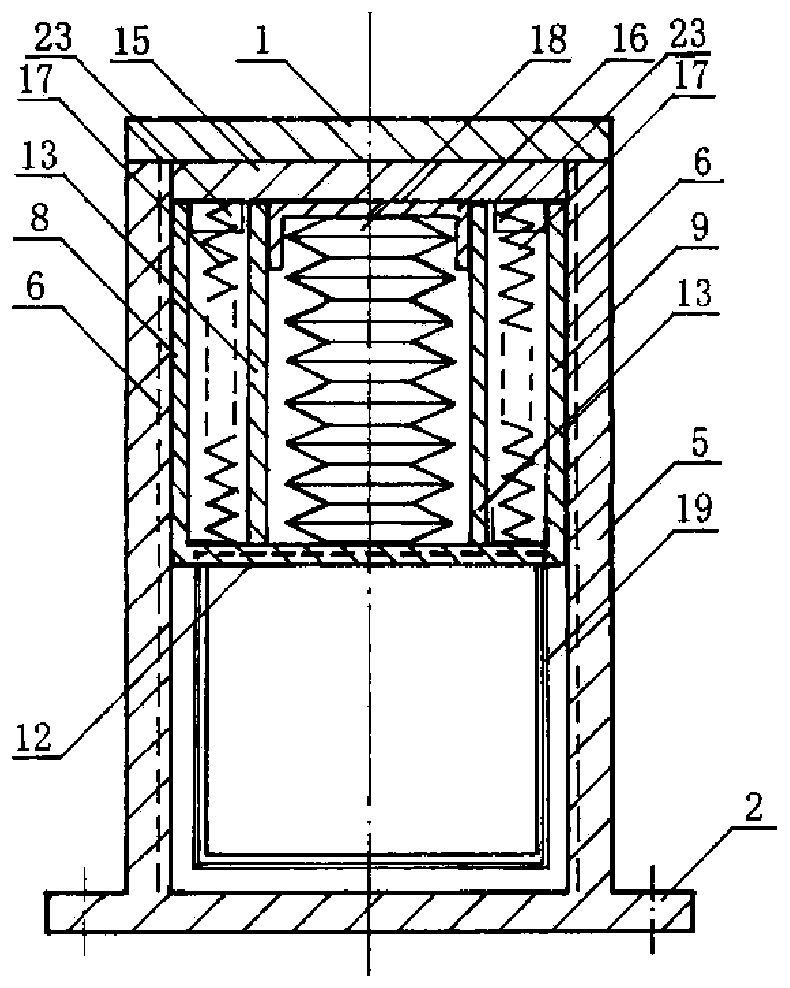

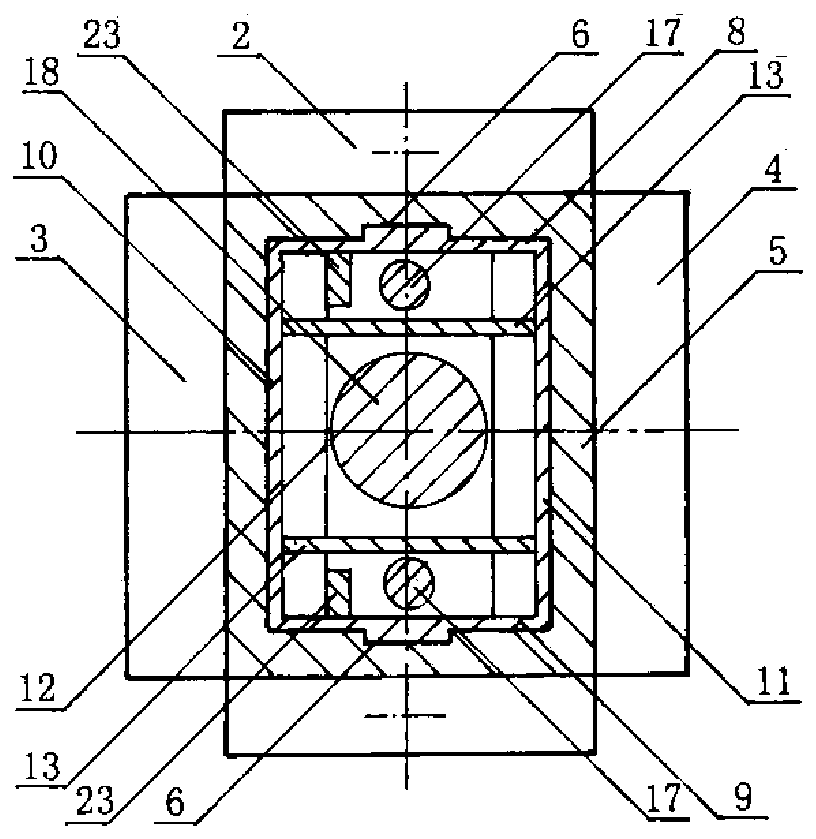

[0021] Such as figure 1 , figure 2 and image 3 As shown, the liquid bag type large-diameter square pipe culvert gate in this embodiment includes a lock chamber 5, a sealing ring a19, a sealing ring b20, a support frame 15, a gate, a liquid bag expansion body 18, a tension spring 17, and a door lock 23. The cover plate 1 and the base 2 have a connecting port a3 at the front end of the culvert gate lock chamber 5, and a connecting port b4 at the rear end of the lock chamber 5. The connecting port a3 and the connecting port b4 are located at the The lock chamber 5 described above is horizontally connected to form a horizontal pipeline. The inner wall of the horizontal pipeline is located directly below the lock chamber to form a groove matching the bottom of the gate. There is a vertically upward tunnel in the lock chamber 5. The entire Described lock chamber 5 is like " tee " shape. The connecting port a3, the connecting port b4, and the inner hole of the lock chamber 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com