Horizontal well multi-parameter estimation method based on conducting probe array sensor

An array sensor and conductivity probe technology, which is applied in earth-moving drilling, wellbore/well components, measurement, etc., can solve the problems of difficult transportation of logging instruments, complicated flow patterns, and decreased oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

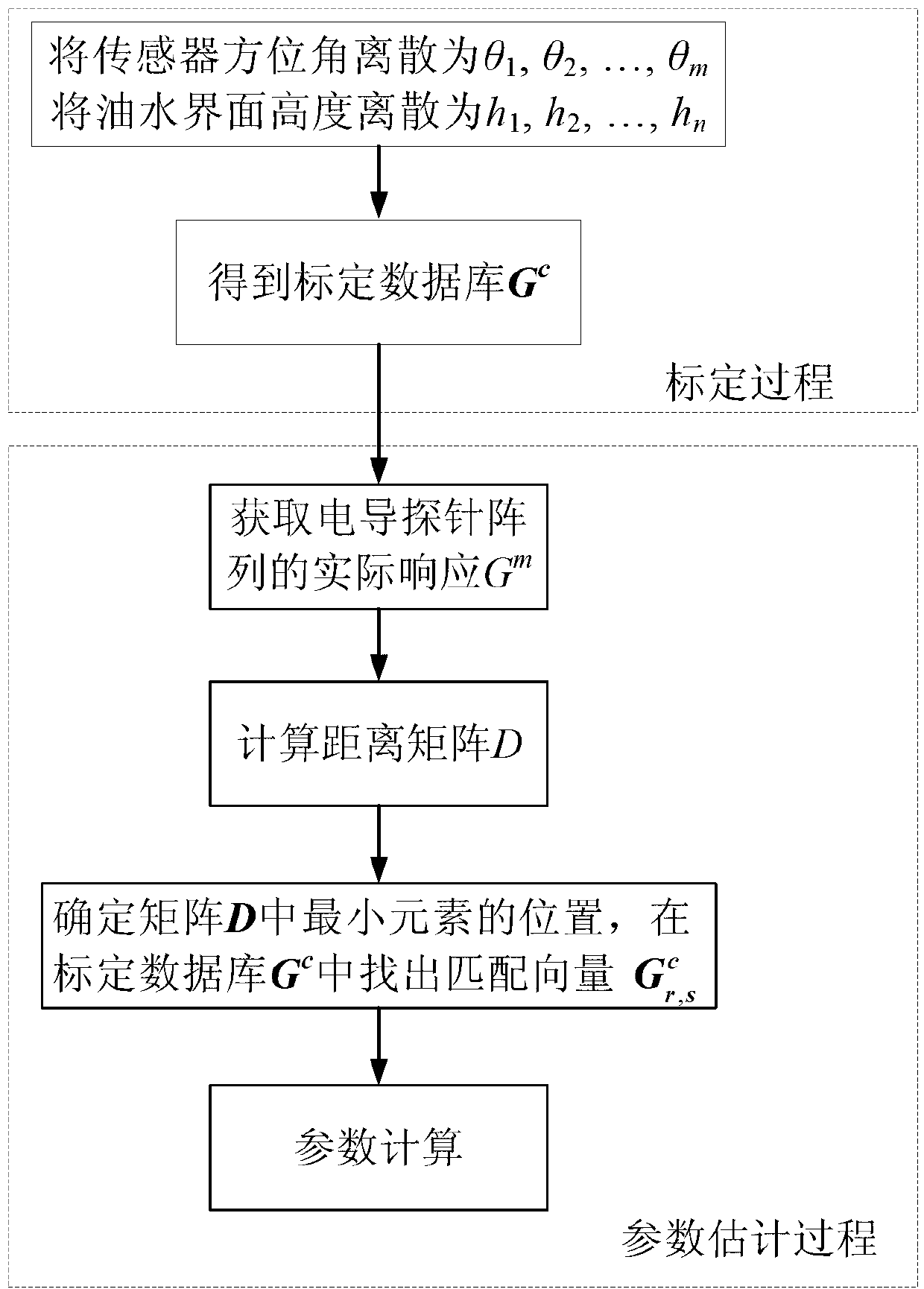

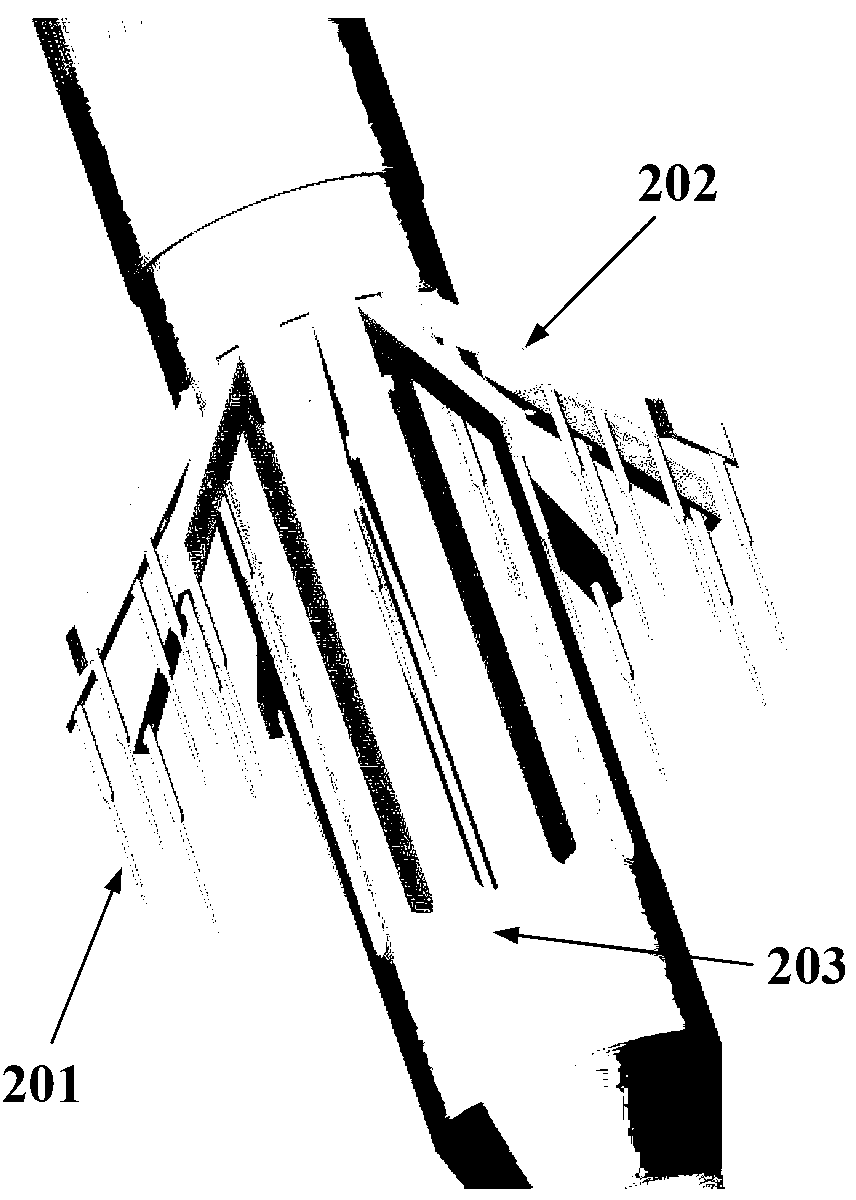

[0023] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings. figure 1 Be the flow chart of the present invention, figure 2 It is a structural diagram of the conductance probe array sensor used in the specific embodiment. The sensor of this structure consists of 24 conductance probes (201) distributed on the inner and outer rings, respectively installed on 12 equiangularly distributed support arms (202 ), the support shaft (203) is coaxial with the horizontal well and is used to fix and support the entire sensor. image 3 It shows the measurement section of the conductivity probe array sensor and the numbering of the probes in the working state, wherein the inner wall of the horizontal well is 125mm, and the outer diameter of the support shaft (302) is 50mm. The azimuth angle of the conductance probe array sensor is the angle it rotates counterclockwise around the support shaft, and the specified image 3 It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com