Plastic steel profile and production technology

A production process and profile technology, applied in the direction of leaf frame, window/door, building components, etc., can solve the problems of poor wind pressure resistance, door and window damage, door and window opening and closing inconvenience, etc., to improve strength and wind pressure resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

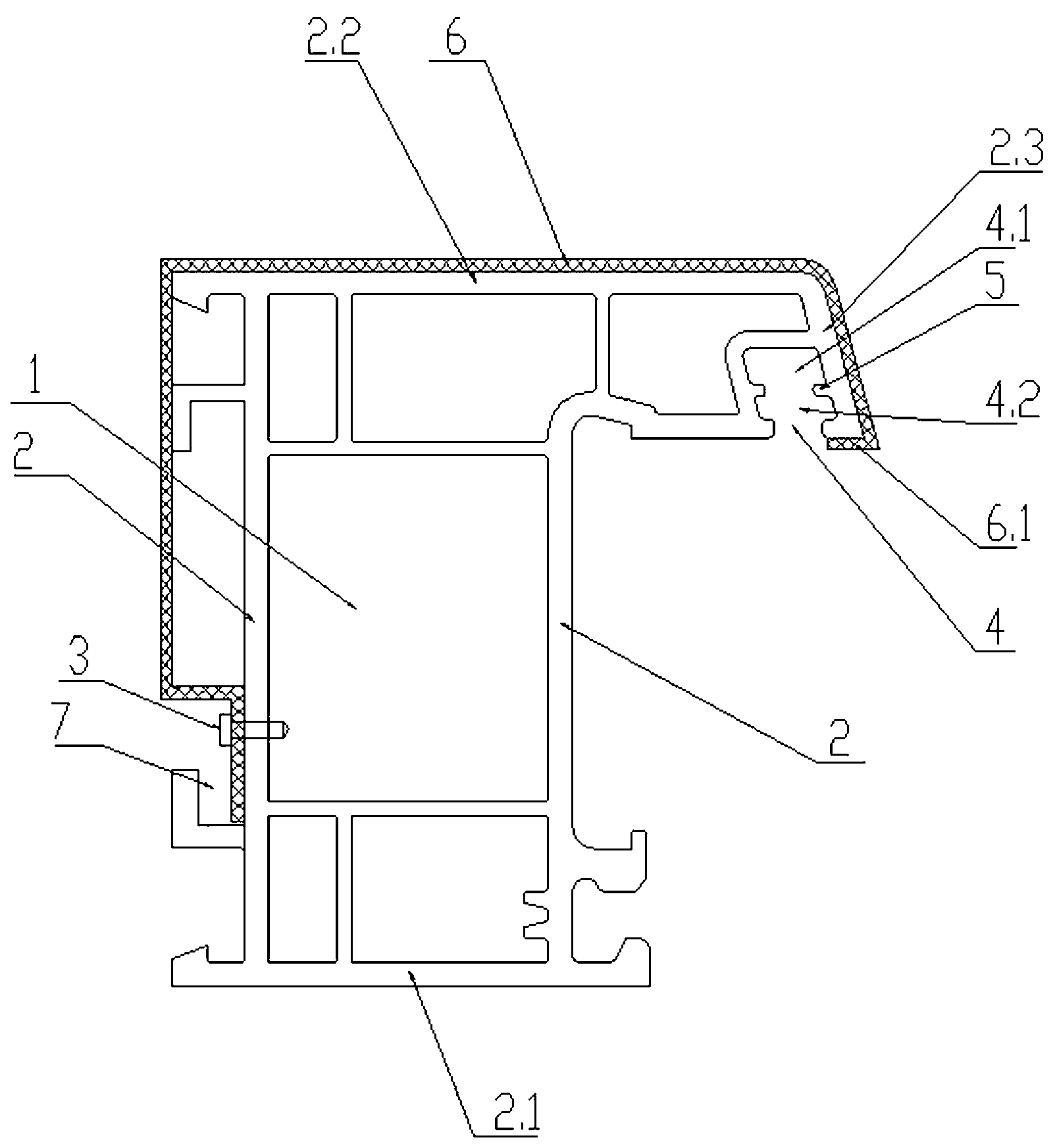

[0032] Embodiment 1: as attached figure 1 As shown in , a plastic steel profile includes a plastic steel profile body 1, which is provided with an outer visible surface 2.2, an inner visible surface 2.1, and two connections for connecting the inner visible surface 2.1 and the outer visible surface 2.2 plate 2, the outer visible surface 2.2 is provided with a metal plate 6; the right edge of the outer visible surface 2.2 of the body 1 is provided with a slope 2.3, and the metal plate 6 extends along the slope 2.3 to The lower edge of the slope 2.3 is chamfered and bent inward to form the hook edge 6.1; the connecting plate 2 on the right side of the body 1 near the hook edge 6.1 is provided with a T-shaped rubber strip inlay groove 4, and the rubber strip inlay groove 4 There is a protrusion 5 on the groove wall, and the protrusion 5 divides the rubber strip inlay groove 4 into a gauze installation groove 4.1 near the bottom of the groove and a rubber strip installation groove ...

Embodiment 2

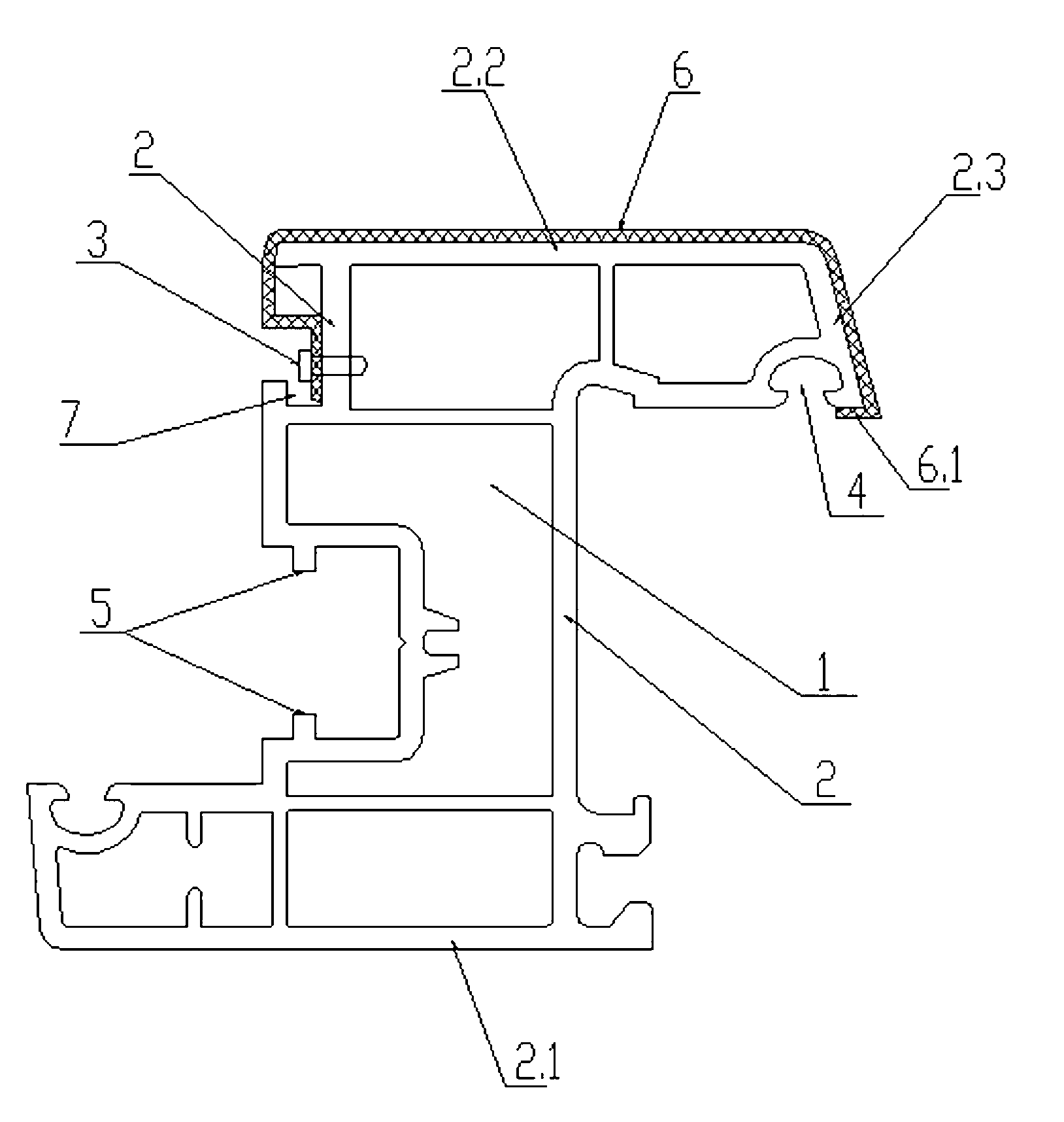

[0043] Embodiment 2: as attached figure 2 As shown in , a plastic-steel window profile includes a plastic-steel profile body 1, which is provided with an outer visible surface 2.2, an inner visible surface 2.1, and two bars for connecting the inner visible surface 2.1 and the outer visible surface 2.2. The connecting plate 2 is provided with a metal plate 6 on the visible outer surface 2.2; a slope 2.3 is provided at the right edge of the visible surface 2.2 of the body 1, and the metal plate 6 extends along the slope 2.3, To the chamfer of the lower edge of the inclined surface 2.3, and bend inward to form the hook edge 6.1; the connecting plate 2 on the right side of the body 1 near the hook edge 6.1 has a T-shaped rubber strip inlay groove 4, and the T-shaped structure The groove bottom of the rubber strip inlay groove 4 is a semicircular structure; the connecting plate 2 on the left side of the body 1 is provided with an edge-holding groove 7 with an opening facing the vi...

Embodiment 3

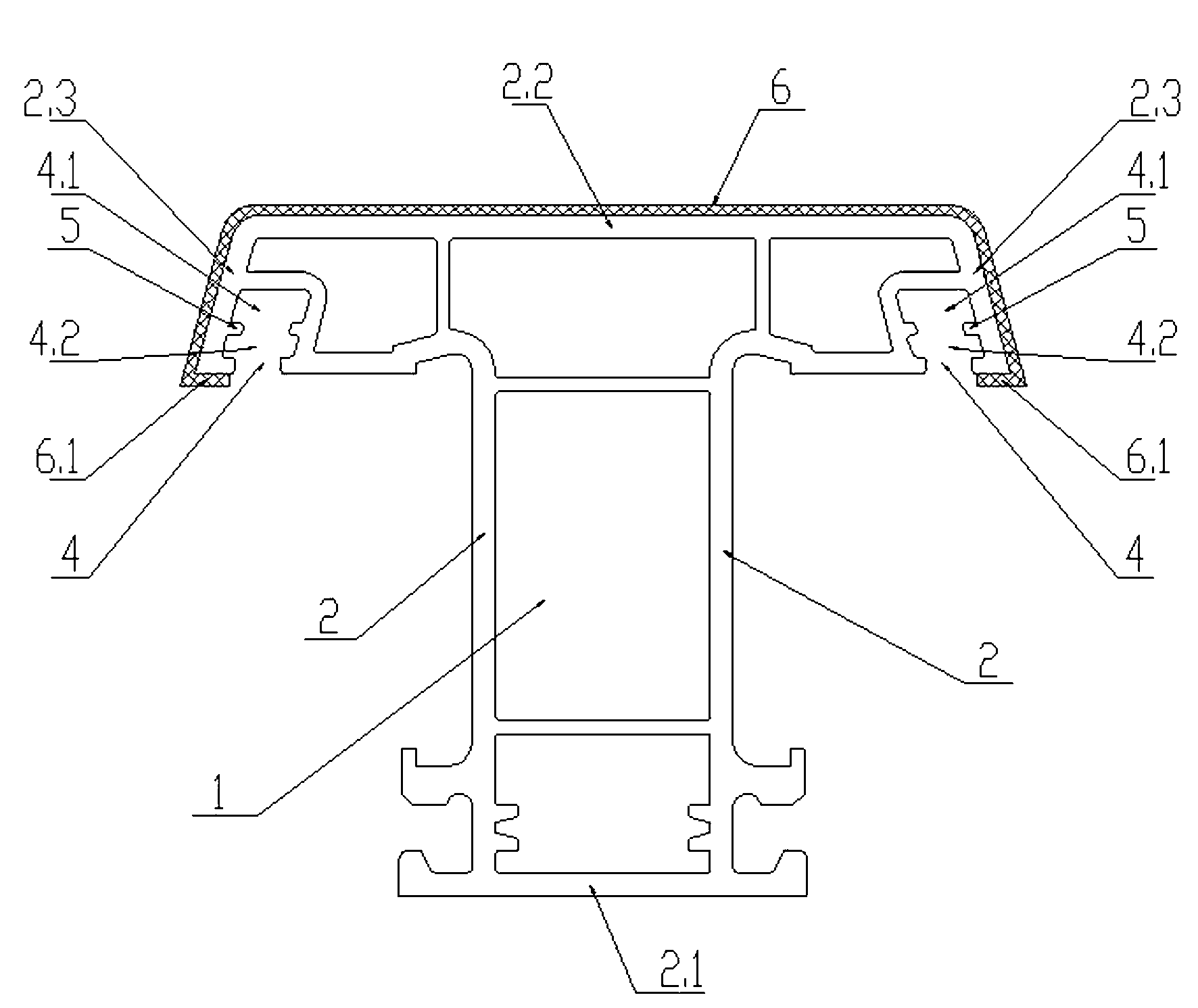

[0055] Embodiment 3: as attached image 3 As shown in , a plastic steel profile includes a plastic steel profile body 1, which is provided with an outer visible surface 2.2, an inner visible surface 2.1, and two connections for connecting the inner visible surface 2.1 and the outer visible surface 2.2 plate 2, the outer visible surface 2.2 is provided with a metal plate 6; the right edge of the outer visible surface 2.2 of the body 1 is provided with a slope 2.3, and the metal plate 6 extends along the slope 2.3 to The lower edge of the slope 2.3 is chamfered and bent inward to form the hook edge 6.1; the connecting plate 2 on the right side of the body 1 near the hook edge 6.1 is provided with a T-shaped rubber strip inlay groove 4, and the rubber strip inlay groove 4 There is a protrusion 5 on the groove wall, and the protrusion 5 divides the rubber strip inlay groove 4 into a gauze installation groove 4.1 near the bottom of the groove and a rubber strip installation groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com