Lead shear damper

A technology of damper and lead block, which is applied in the direction of building components, shockproof, etc., can solve problems such as difficult reset and replacement, achieve high practical value and economic benefits, avoid difficult replacement, and simple factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a further description of the technical content of the patent of the present invention, but it is not a limitation to the essential content of the patent of the present invention.

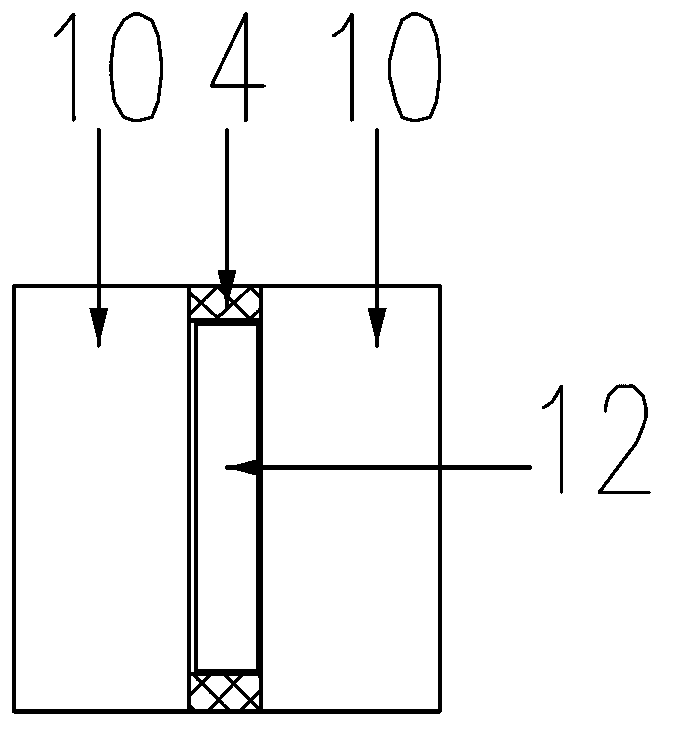

[0023] The lead shear damper comprises an upper cover plate 2 and a lower cover plate 3, one end of the upper cover plate 2 is provided with a fixed end plate 9, and the other end is provided with an upper return spring 5, and the upper return spring 5 is fixed on the sliding end end plate 7 One end of the lower cover plate 3 is connected to the sliding end plate 7, the other end is connected to the lower return spring 6, the lower return spring 6 is fixed on the fixed end end plate 9, the upper cover plate 2 is superimposed on the lower cover plate 3, and the upper cover plate 2 The part connected with the lower cover plate 3 is provided with a shearing lead block 1 .

[0024] It also lies in that the restraint cylinder 4 is wrapped around the upper cover plate 2, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com