Feeding device for winding machine

A technology of feeding device and winding device, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems such as the inability to convey the steel belt, the inability to achieve positioning, and the easy occurrence of deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

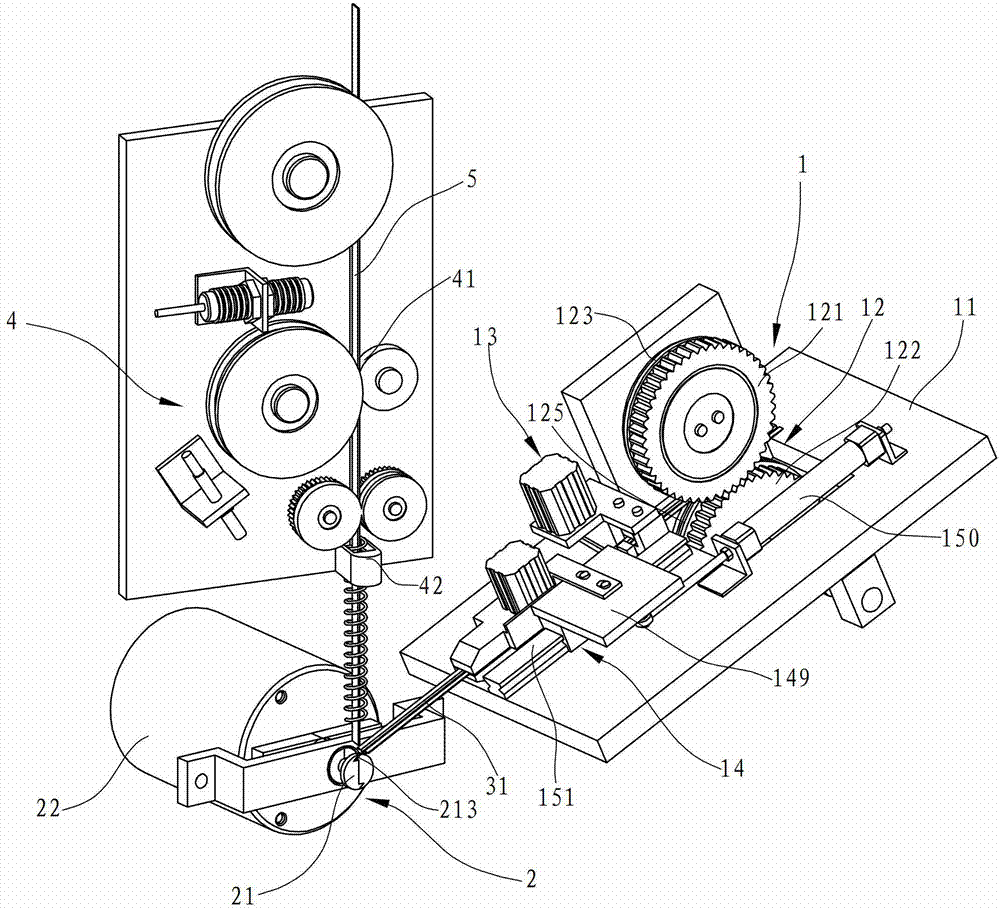

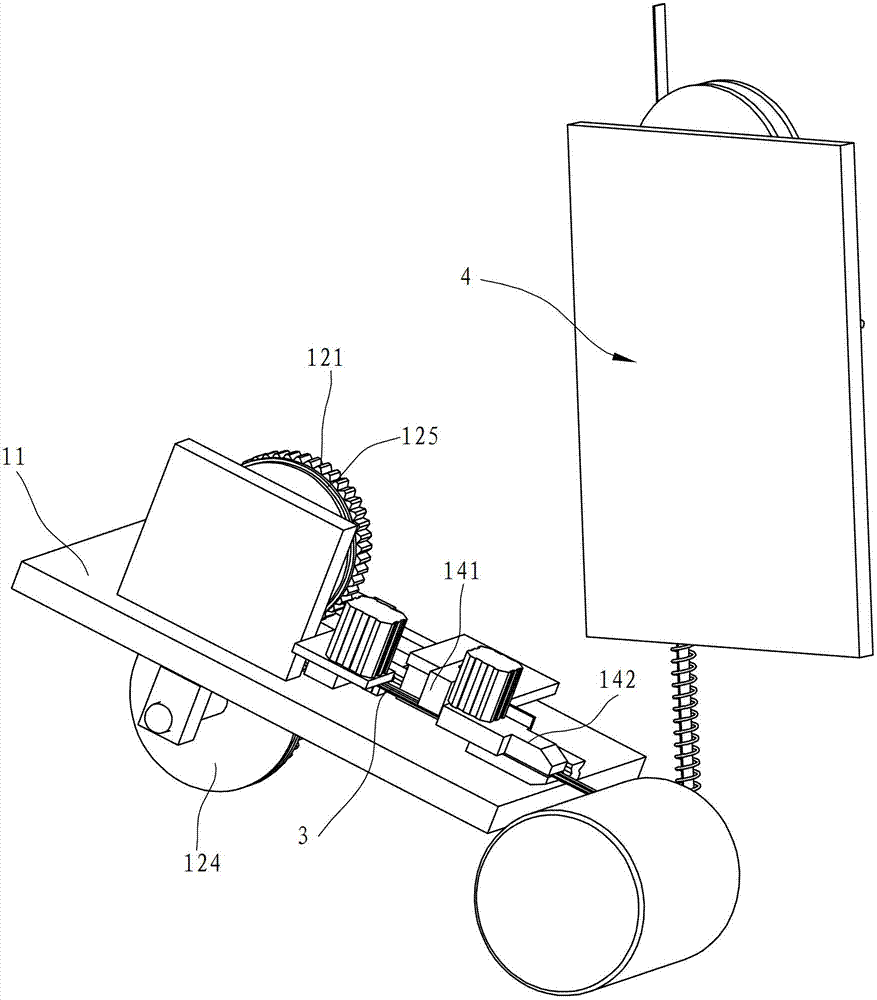

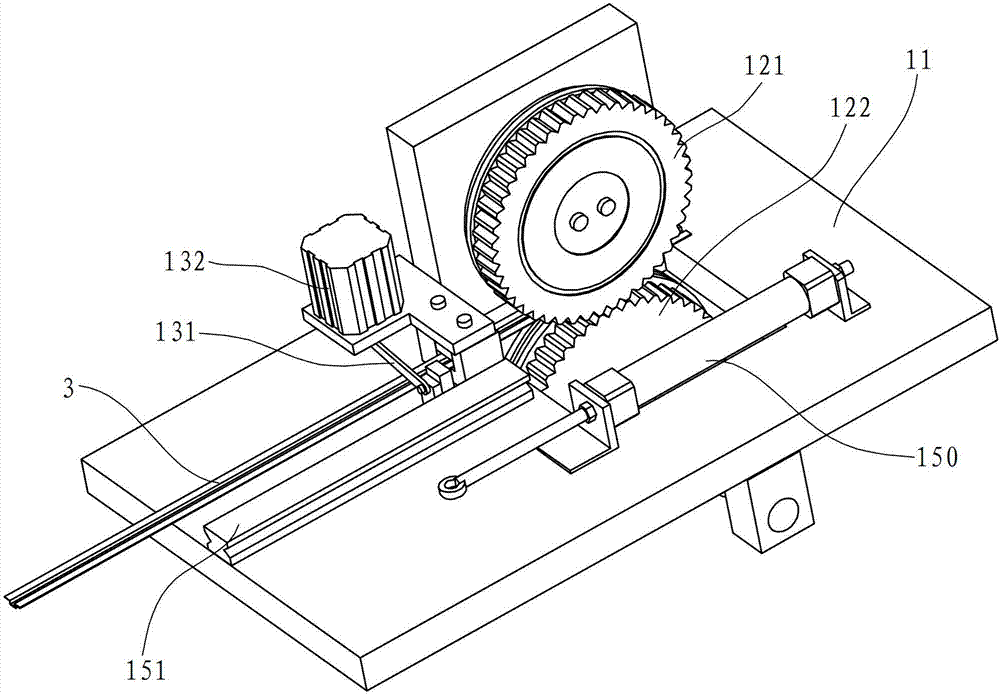

[0020] see Figure 1-Figure 3 , a fully automatic winding machine, comprising a feeding device 1 and a winding device 2 arranged adjacently. The feeding device 1 includes a main frame 11 inclined to the direction of the winding device 2 , a punching mechanism 12 , a shearing mechanism 13 and a guiding mechanism 14 arranged on the main frame 11 in sequence.

[0021] The notching mechanism 12 includes a first gear 121 and a second gear 122 which are arranged up and down and mesh with each other, and a first wheel 123 which rotates synchronously with the first gear 121, a second wheel 124 which rotates synchronously with the second gear 122, The peripheral edges of the first rotating wheel 123 and the second rotating wheel 124 are in contact, and one of the rotating wheels has a protruding portion 125 on the peripheral edge, which can drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com