Automatic spherical surface coating machine

A spraying machine, fully automatic technology, applied in the direction of spraying device, can solve the problems of unguaranteed quality, low production capacity, poor production environment for workers, etc., to achieve the effect of saving capital, stable quality, easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

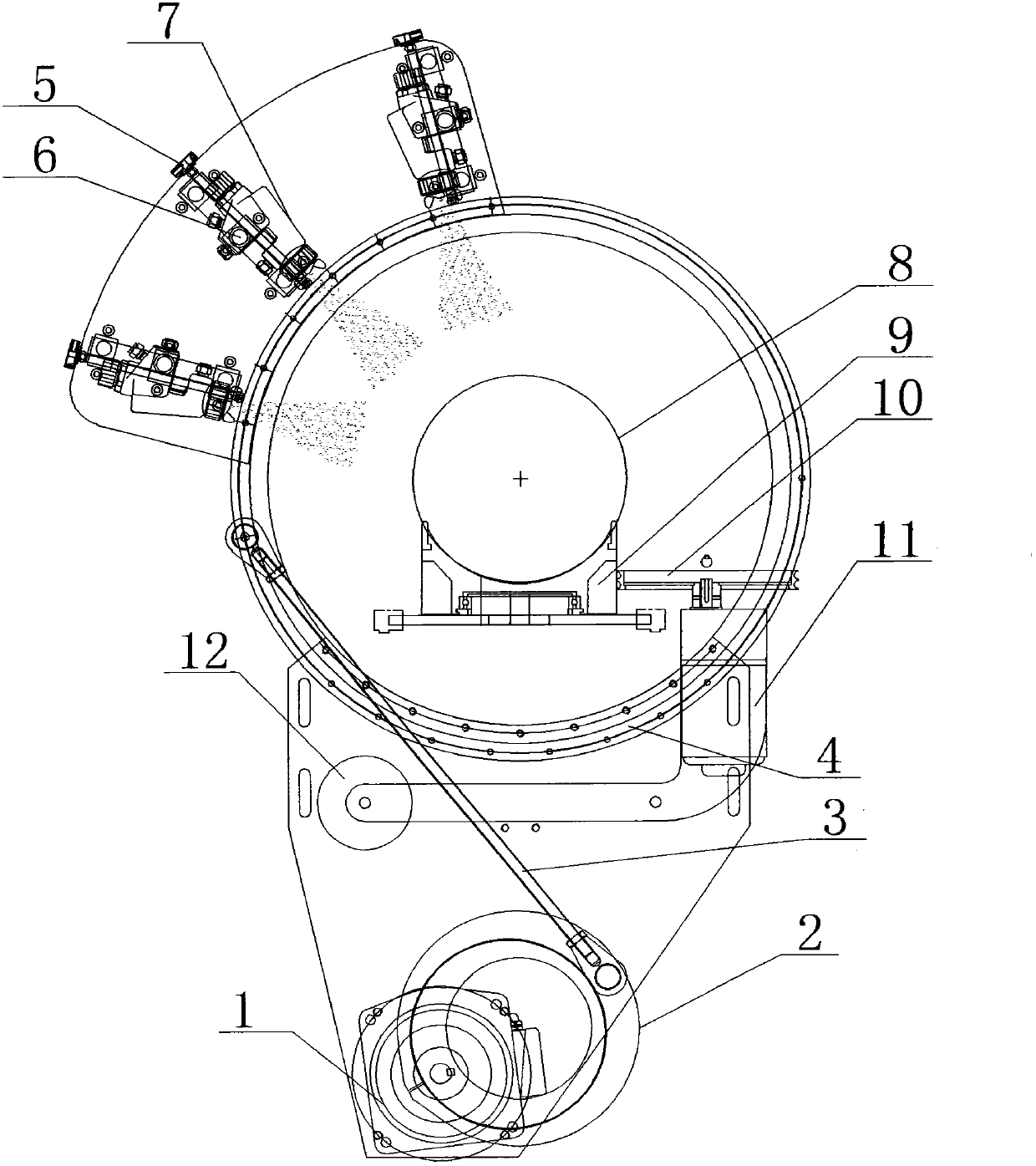

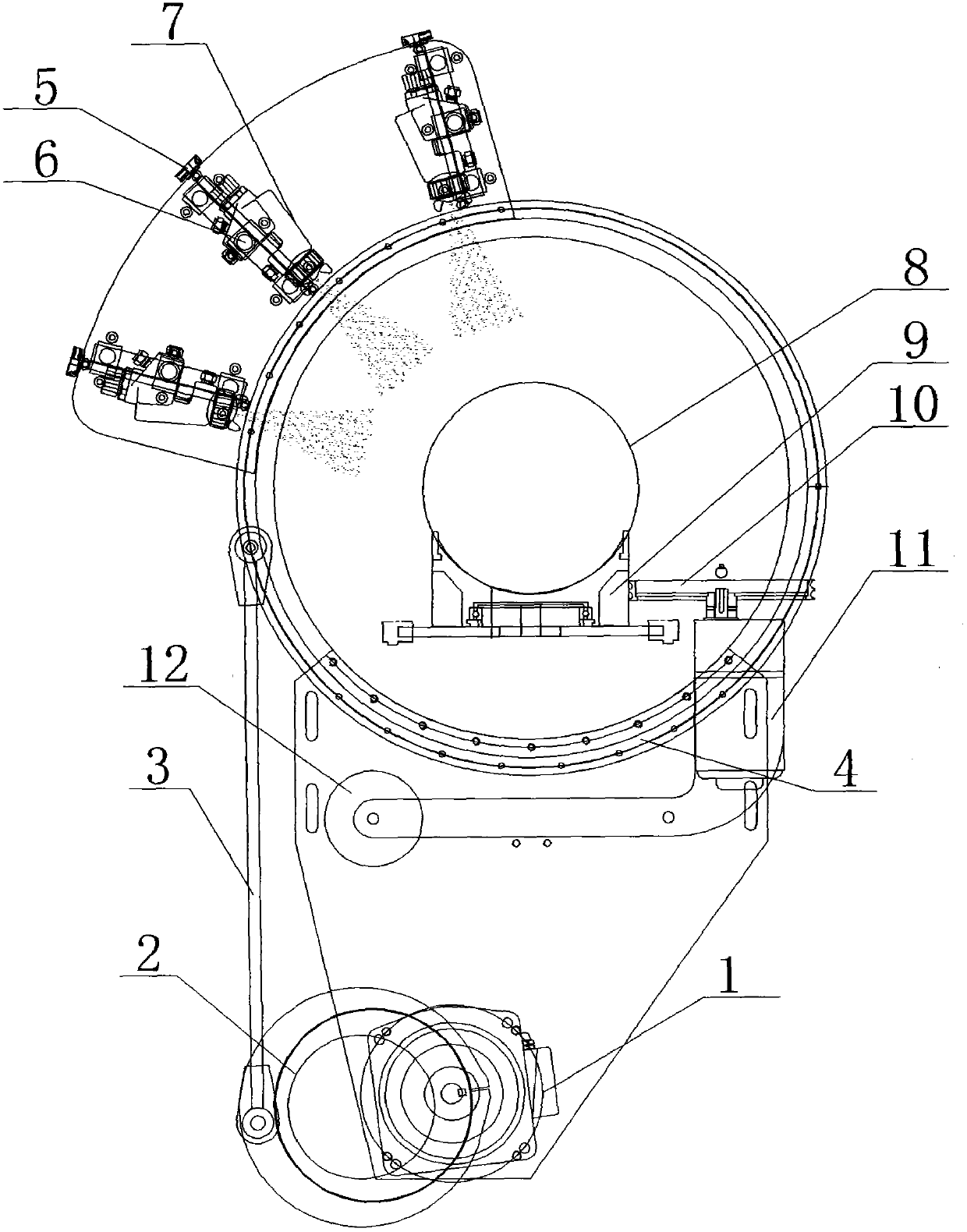

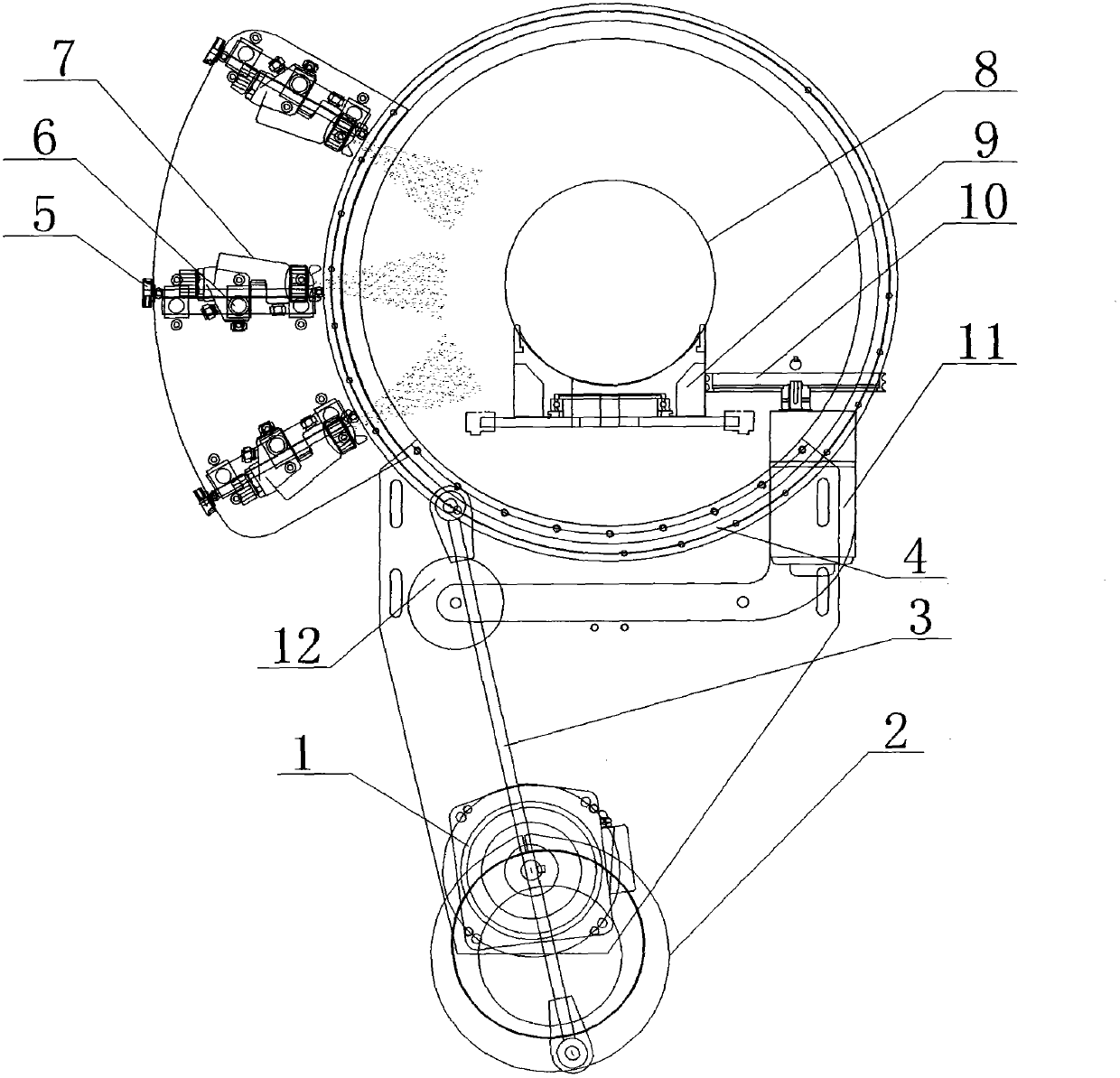

[0011] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the drawings, the structure of the present invention includes a swing motor 1, an eccentric 2, a connecting rod 3, a disc bearing 4, a regulator 5, a mounting rod 6, a spray gun 7, a spherical workpiece 8, a self-priming fixture 9, a friction wheel 10. The rotating motor 11 and the tightening device 12 are characterized in that the disc bearing 4 is provided with three regulators 5, the regulator 5 is provided with a mounting rod 6, and the mounting rod 6 is provided with a spray gun 7, and the regulator 5 can Adjust the distance from the spray gun 7 to the surface of the spherical workpiece 8. The angle of the spray gun 7 can also be adjusted through the regulator 5. An eccentric 2 is arranged under the disc bearing 4. The disc bearing 4 is connected with the eccentric 2 through a connecting rod 3. The eccentric 2 Set on the rotating shaft of the swing motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com