Flue gas desulfurization synergist for wet desulfurization system, and preparation method and application thereof

A wet desulfurization and synergist technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem that the desulfurization system cannot operate normally, the absorption tower equipment is blocked and fouled, and the sulfur content of coal is poorly adapted. and other problems, to achieve the effect of shortening the desulfurization reaction time, good environmental and economic benefits, and slowing down the fouling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A flue gas desulfurization synergist for a wet desulfurization system, calculated by weight percentage, its composition and content are as follows:

[0036] Magnesium salt 23%

[0037] Sodium salt 46%

[0038] Organic amines 31%.

[0039] Described magnesium salt is magnesium sulfate;

[0040] The sodium salt is disodium EDTA;

[0041] The organic amine is ethylene bismorpholine.

[0042] The preparation method of the above-mentioned flue gas desulfurization synergist for a wet desulfurization system, the steps are as follows:

[0043] The flue gas desulfurization synergist for wet desulfurization system is obtained by mixing magnesium salt, sodium salt and organic amine and stirring evenly.

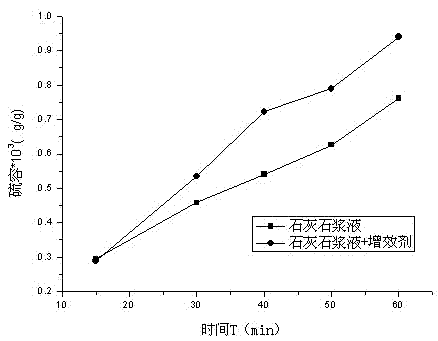

[0044] Determination of the effect of the flue gas desulfurization synergist of the wet desulfurization system obtained in Example 1 on the sulfur capacity of the limestone slurry.

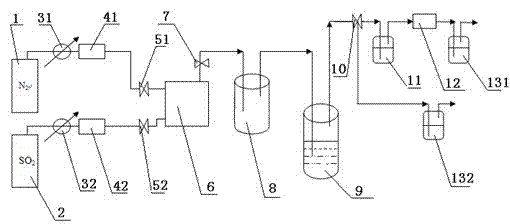

[0045] A schematic diagram of the apparatus used for the determination of figure 1 as sho...

Embodiment 2

[0052] A flue gas desulfurization synergist for a wet desulfurization system, calculated by weight percentage, its composition and content are as follows:

[0053] Magnesium salt 1%

[0054] Sodium salt 66%

[0055] Organic amine 33%;

[0056] Described magnesium salt is magnesium sulfate;

[0057] Described sodium salt is sodium humate;

[0058] Described organic amine is methyldiethanolamine.

[0059] The preparation method of the above-mentioned flue gas desulfurization synergist for a wet desulfurization system, the steps are as follows:

[0060] The flue gas desulfurization synergist for wet desulfurization system is obtained by mixing magnesium salt, sodium salt and organic amine and stirring evenly.

Embodiment 3

[0062] A flue gas desulfurization synergist for a wet desulfurization system, calculated by weight percentage, its composition and content are as follows:

[0063] Magnesium salt 49%

[0064] Sodium salt 8%

[0065] Organic amine 43%;

[0066] Described magnesium salt is magnesium sulfate;

[0067] Described sodium salt is disodium EDTA;

[0068] The organic amine is ethylene bismorpholine.

[0069] The preparation method of the above-mentioned flue gas desulfurization synergist for a wet desulfurization system, the steps are as follows:

[0070] The flue gas desulfurization synergist for wet desulfurization system is obtained by mixing magnesium salt, sodium salt and organic amine and stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com