Vacuum infiltration device and method for pretreatment in animal and plant extraction processes

An extraction process and infiltration device technology, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the problems of insufficient infiltration of solvents, lack of infiltration devices, and reduced production efficiency. Eliminate microbial growth, good infiltration effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

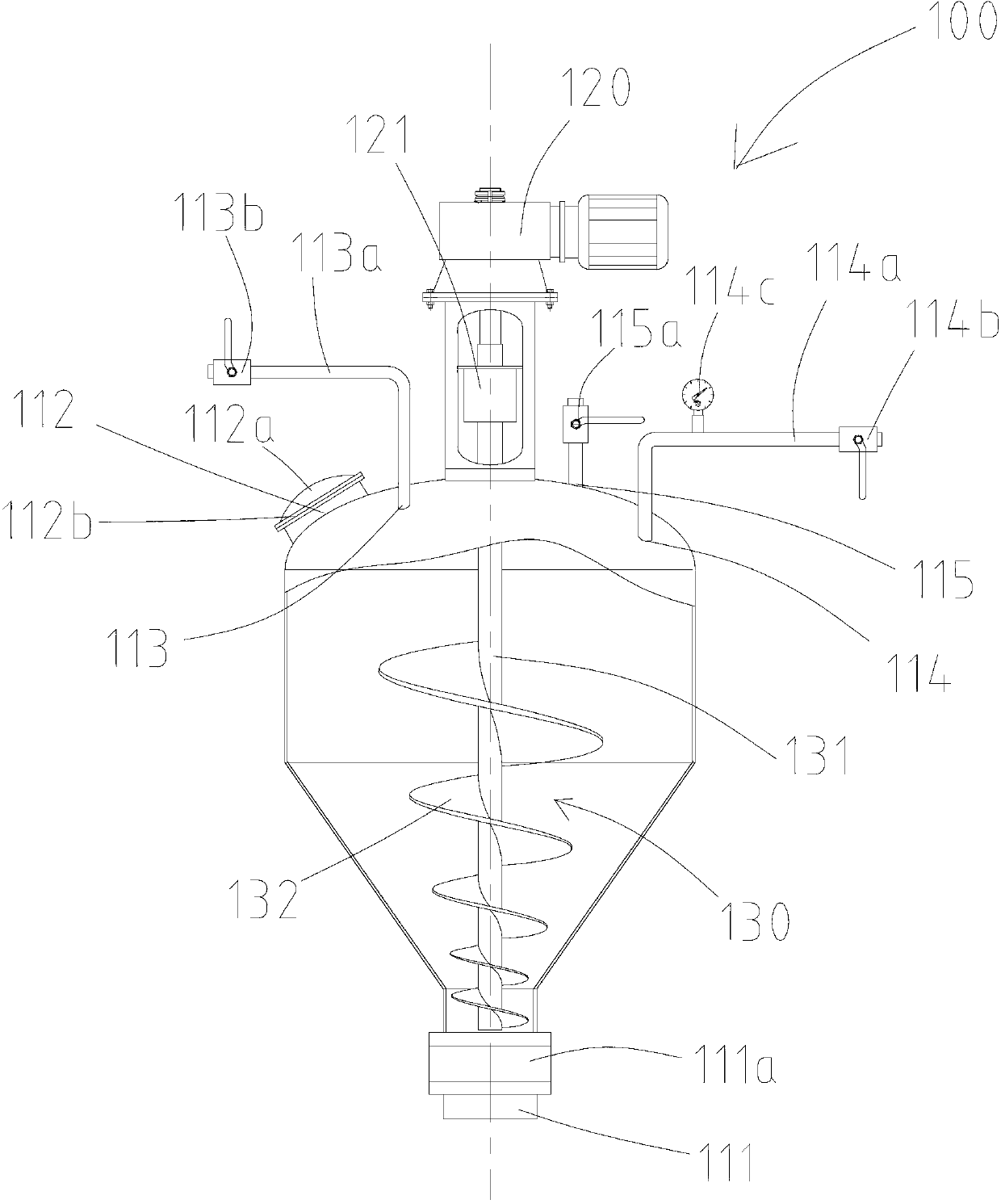

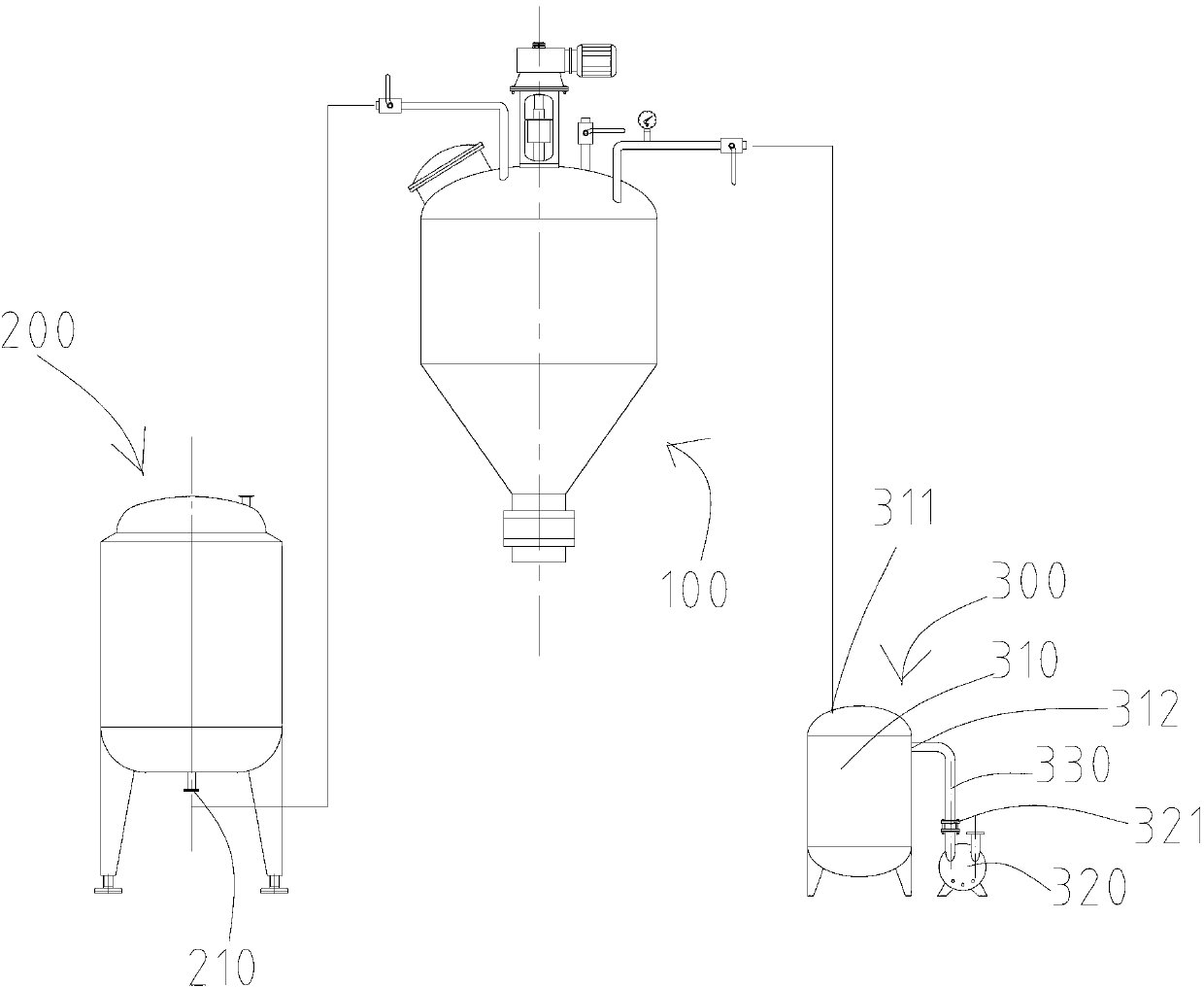

[0045] see figure 1 and figure 2 As shown, a vacuum infiltration device used for pretreatment of animal and plant extraction process includes an infiltration tank 100, a liquid storage tank 200 and a vacuum device 300, and the infiltration tank 110 is provided with a discharge port 111, a vacuum release port 115, and a feed port 112 , liquid filling port 113 and vacuum pumping port 114, discharge port 111, vacuum release port 115, liquid filling port 113 and vacuum pumping port 114 are respectively provided with switch valves 111a, 115a, 113b, 114b, and feeding port 112 is equipped with The cover 112a is sealed and sealed by a sealing ring 112b. The lower part of the infiltration tank 1000 is in an inverted cone shape, so that the extracted ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com