A kind of preparation method of near-infrared photoelectric silicon material

A near-infrared optical and electrical material technology, which is applied in the preparation of near-infrared optoelectronic materials, can solve the problems of affecting optoelectronic properties and the decrease of sulfur ion concentration, and achieves the effect of high near-infrared absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

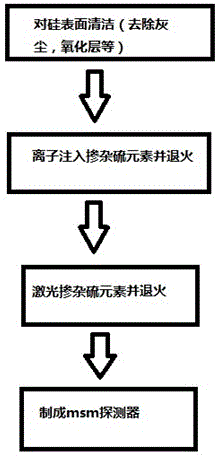

[0031] Such as figure 1 As shown in, the preparation method of the near-infrared photoelectric silicon material provided in this embodiment includes the following steps:

[0032] (1) Clean the surface of the single crystal silicon. The cleaning process includes placing the silicon in an acetone solution, placing the acetone solution soaked with the silicon wafer in the ultrasonic chamber, turning on the switch of the ultrasonic chamber, and taking out the cleaned silicon after 20 minutes. slice, and load it on the stage of the vacuum chamber;

[0033] (2) Perform heavy sulfur doping on the crystalline silicon wafer, vacuumize the vacuum chamber, and adjust the pressure to 1×10 -3 Below Pa, open the inflation valve and flush into the background gas SF at a flow rate of 40 sccm 6 , until the pressure in the vacuum chamber is 0.5±0.01pa, after the pressure in the vacuum chamber is stable, turn on the femtosecond (or nanosecond) laser and adjust the laser intensity to 1.8J / cm 2...

Embodiment 2

[0039] like figure 1 As shown in, the preparation method of the near-infrared photoelectric silicon material provided in this embodiment includes the following steps:

[0040] (1) Clean the surface of monocrystalline silicon. The cleaning process includes placing the silicon in acetone solution for several minutes, placing the acetone solution soaked with silicon wafers in the ultrasonic chamber, turning on the switch of the ultrasonic chamber, and taking it out for 20 minutes to complete the cleaning. The silicon wafer is loaded on the stage of the vacuum chamber;

[0041] (2) Perform heavy sulfur doping on the crystalline silicon wafer, vacuumize the vacuum chamber, and adjust the pressure to 1×10 -3 Below Pa, open the inflation valve and flush into the background gas SF at a flow rate of 40 sccm 6 , until the pressure in the vacuum chamber is 0.5±0.01pa, after the pressure in the vacuum chamber is stable, turn on the femtosecond (or nanosecond) laser and adjust the laser in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com