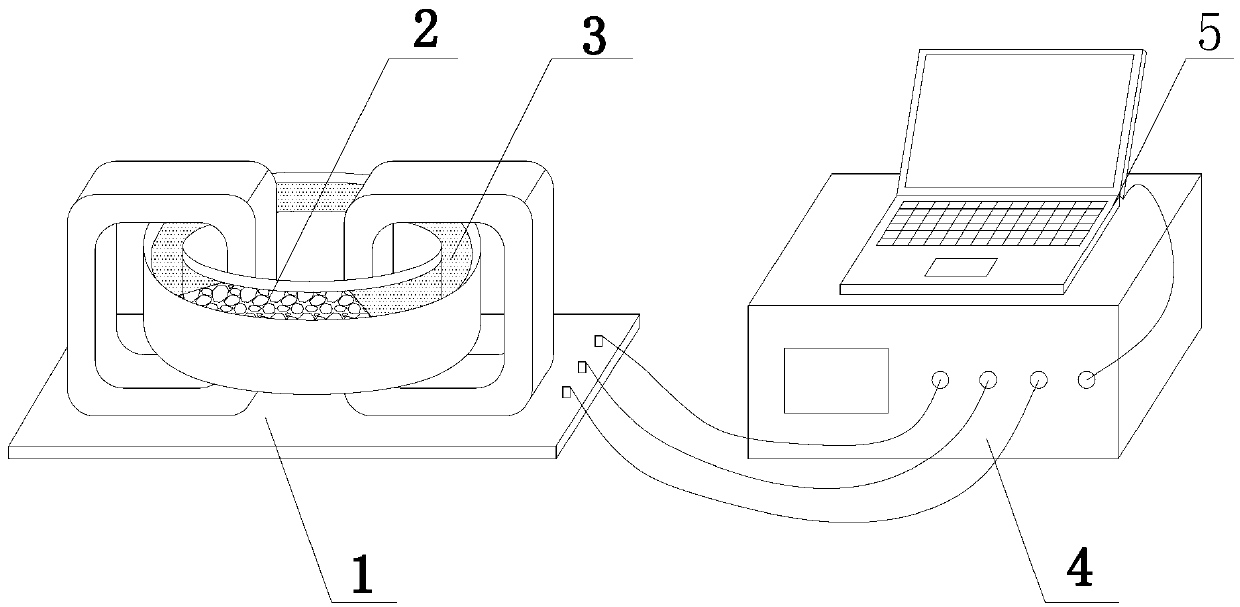

Method and system for non-contact electrical resistivity-based evaluation of permeability of cement-based material

A cement-based material, non-contact technology, applied in the direction of permeability/surface area analysis, suspension and porous material analysis, measurement devices, etc., can solve the problems of long test time, affecting test results, large test errors, etc., and achieve test results The effect of short cycle, low test cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

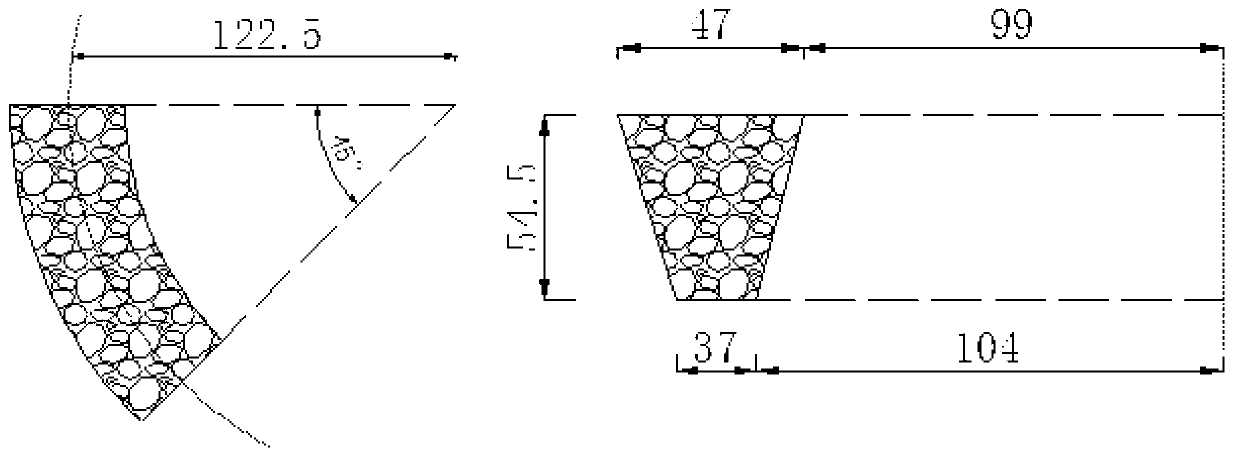

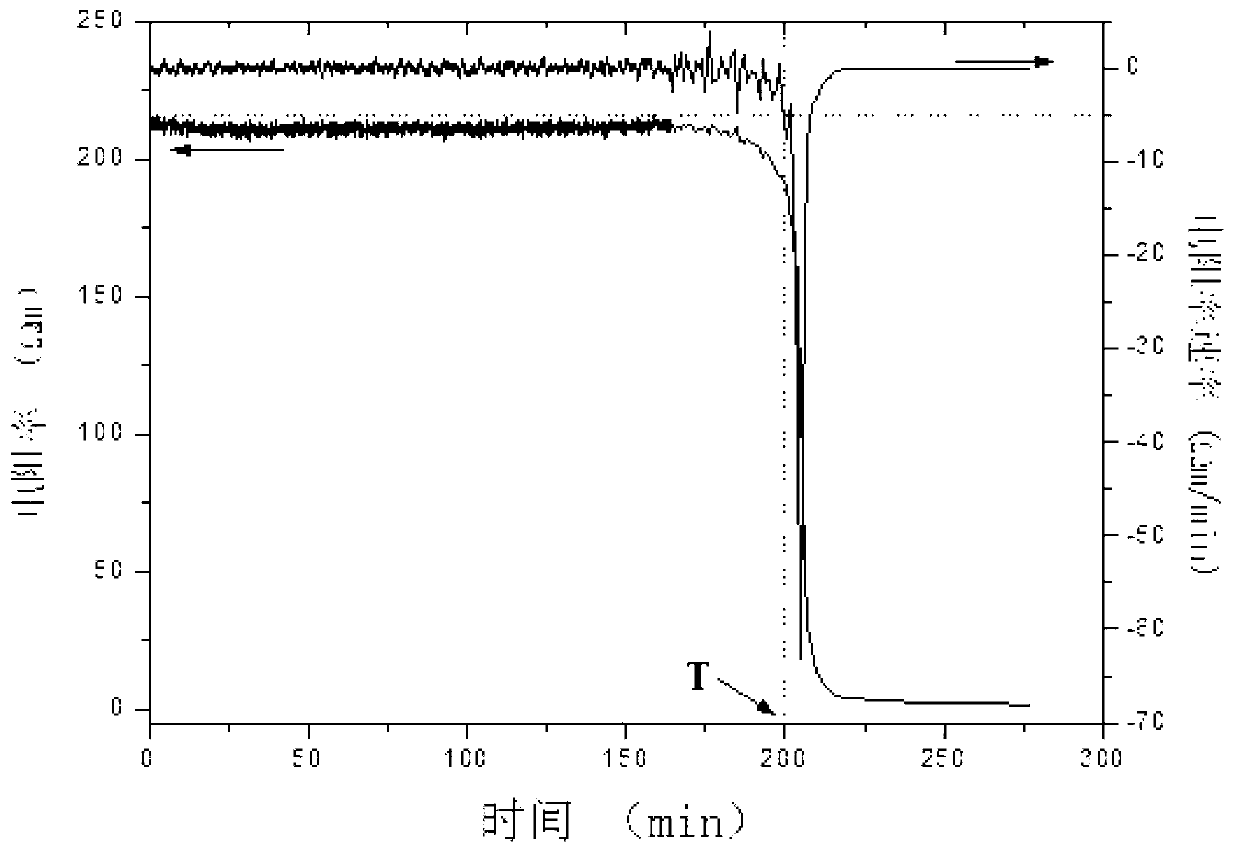

Embodiment example 1

[0045] The detection method of the present invention is used to investigate the permeability of cement slurry. The non-contact resistivity tester used is the CCR2 tester produced by Zhongheng Gangke (Shenzhen) Technology Co., Ltd. The water-cement ratio of the cement paste is 0.60, and the curing period is 7 days. Two test pieces are used for each group of cement slurry, the arc angle of the test piece is π / 2, the concentration of sodium chloride solution is 1mol / L, and the sampling frequency is 0.167Hz. Among them, the cement is P·O 52.5 grade ordinary Portland cement produced by Hubei Huaxin Cement Factory, with a specific surface area of 350 m 2 / kg; water is tap water. The test results of resistivity mutation time and permeability rate of cement paste samples are shown in Table 1.

[0046] Table 1 Test results of cement slurry penetration rate

[0047] Sample serial number Resistivity mutation time T (s) Permeation rate V (10 -6 m / s) 1 12006 4.00...

Embodiment example 2

[0050] The detection method of the present invention is used to investigate the permeability of cement slurry. The non-contact resistivity tester used is the CCR2 tester produced by Zhongheng Gangke (Shenzhen) Technology Co., Ltd. The water-cement ratio of the cement slurry is 0.60, 0.53 and 0.45 respectively, and the curing period is 28 days. Two test pieces are used for each group of cement slurry, the arc angle of the test piece is π / 2, the concentration of sodium chloride solution is 1mol / L, and the sampling frequency is 0.167Hz. Among them, the cement is P·O 52.5 grade ordinary Portland cement produced by Hubei Huaxin Cement Factory, with a specific surface area of 350 m 2 / kg; water is tap water. The test results of resistivity mutation time and permeability rate of cement paste samples can be seen in Table 2.

[0051] Table 2 Resistivity mutation time and permeability performance of cement slurry with different water-cement ratios

[0052]

[0053] Table 2 show...

Embodiment example 3

[0055] The detection method of the present invention is used to investigate the permeability of concrete. The non-contact resistivity tester used is the CCR2 tester produced by Zhongheng Gangke (Shenzhen) Technology Co., Ltd. The mix ratio of concrete can be seen in Table 3, and the penetration rates of concrete 12h, 18h, 1d, 2d, 3d, 7d, 14d and 28d were tested respectively. Two test pieces are used for each group of cement slurry, the arc angle of the test piece is π / 2, the concentration of sodium chloride solution is 1mol / L, and the sampling frequency is 0.167Hz. Among them, the cement is P·O 52.5 grade ordinary Portland cement produced by Hubei Huaxin Cement Factory, with a specific surface area of 350 m 2 / kg; river sand is used as fine aggregate, and the fineness modulus is 2.5-2.6; coarse aggregate is crushed stone with continuous grading of 5-20 mm; tap water is used as water. The test results of resistivity mutation time and permeability rate of cement slurry sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com