Low-torque valve switching device and application

A technology of valve switching and low torque, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc. It can solve the problems of valve drive that cannot achieve low power consumption, large drive torque of the spool, and low cost, and achieve torque Small, easy to drive, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

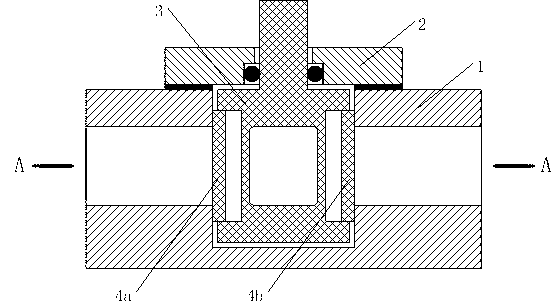

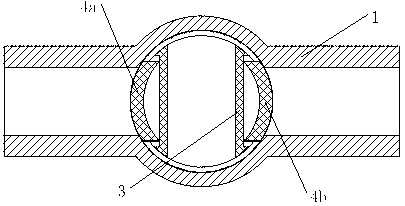

[0024] see figure 1 , is a cross-sectional view of an embodiment of the valve switch device of the present invention,

[0025] This embodiment includes a valve body 1, a valve cover 2, a valve core 3, a first blocking piece 4a, and a second blocking piece 4b. The valve body 1 and the valve cover 2 form a cylindrical valve cavity with top and left and right openings, and the valve core 3 is located in the valve cavity. The middle part of the spool 3 is provided with a horizontal through hole connecting the left and right openings; the horizontal sides of the spool 3 perpendicular to the opening direction of the through hole are respectively provided with grooves; the first baffle 4a and the second baffle 4b are respectively located In the grooves on both sides of the core 3.

[0026] The valve core 3 includes a rotating shaft at the top, and the rotating shaft is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com